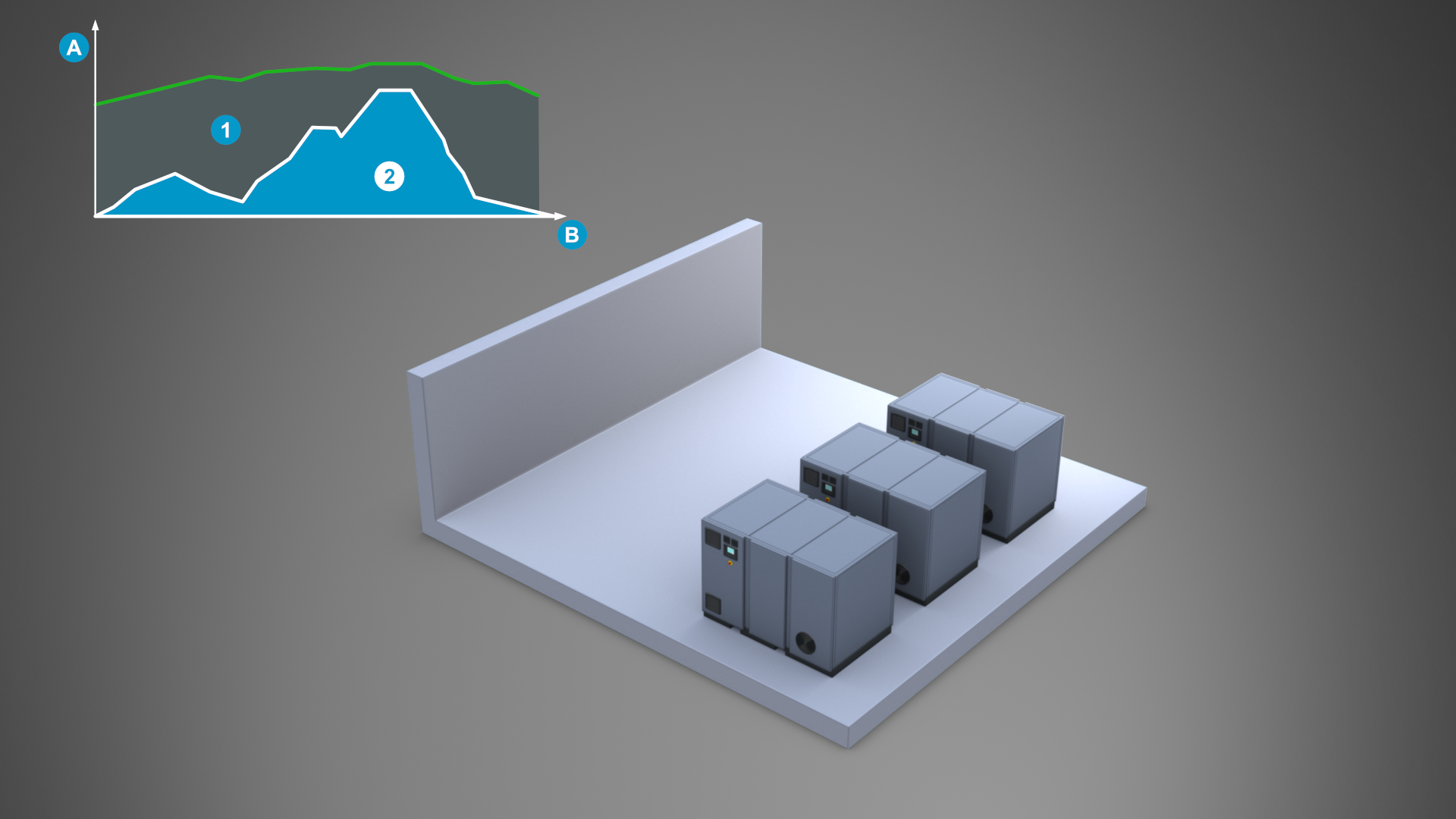

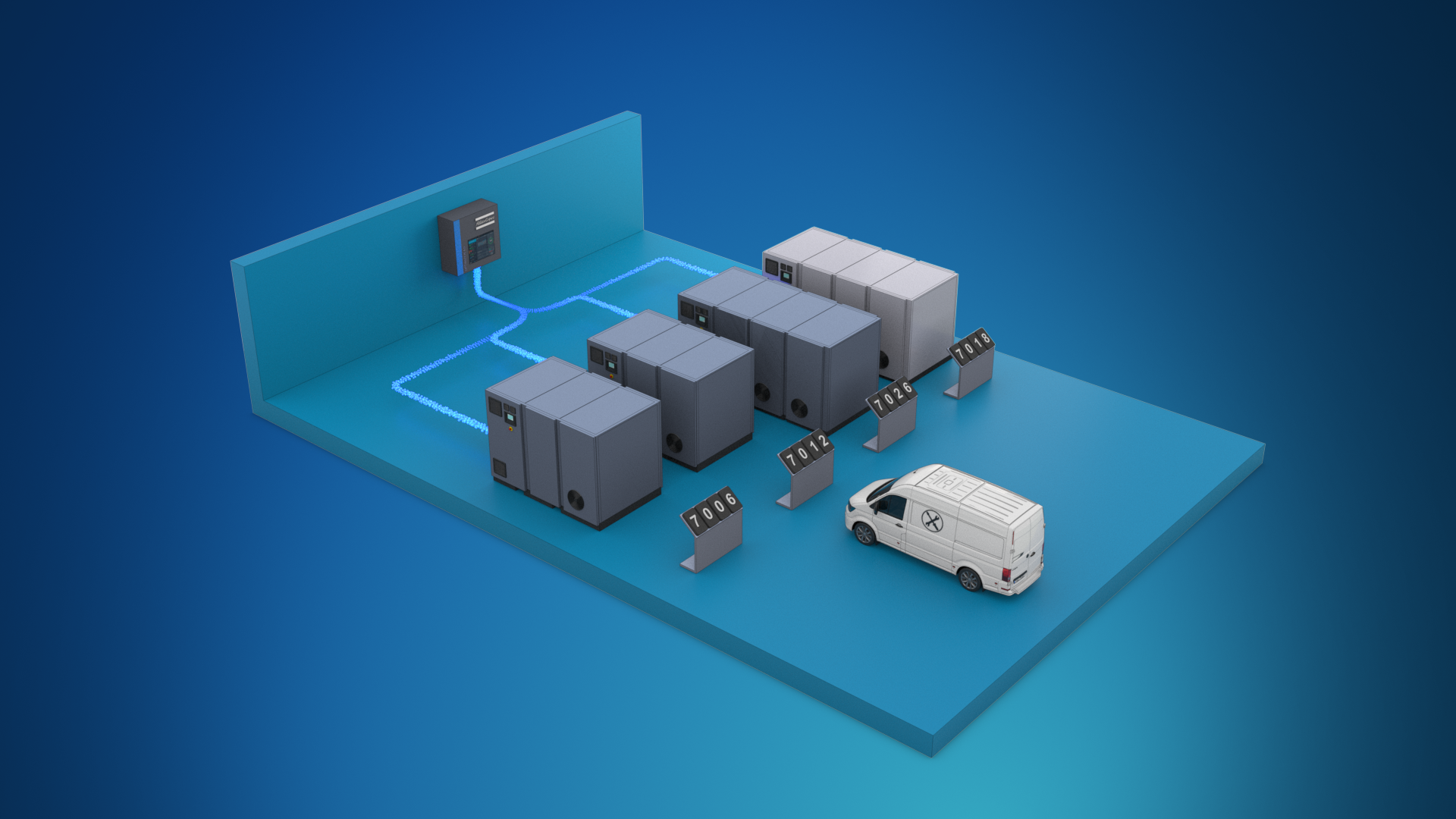

In a well-designed compressed air and blower setup, centralized management of the equipment leads to maximum overall efficiency.

Conserve energy with intelligent control systems

1. Energy Management System

Both the Optimizer 4.0 and Equalizer 4.0 PRO comply with ISO50001 standards as centralized energy and maintenance management solutions. These intelligent central controllers effectively manage all connected equipment to minimize energy consumption.

- The Optimizer 4.0 and Equalizer 4.0 PRO communicate with various machines, continuously monitoring their real-time operating points.

- Variable Speed Drive (VSD) machines function within their optimal ranges, while fixed-speed machines minimize unload time, maximizing overall system efficiency.

- Utilizing a central controller allows for a narrower pressure band, leading to greater energy savings.

- The Optimizer 4.0 can include a Smart subscription, which incorporates artificial intelligence to further enhance energy efficiency.

Implementing an ISO50001-compliant Energy Management System can significantly reduce production costs and deliver the lowest Total Cost of Ownership.

2. Setpoint control

Systems that operate based on a pressure or flow setpoint can be seamlessly incorporated into the Optimizer 4.0. Since the Equalizer 4.0 PRO functions as a sequencer, it includes built-in pressure control capabilities.

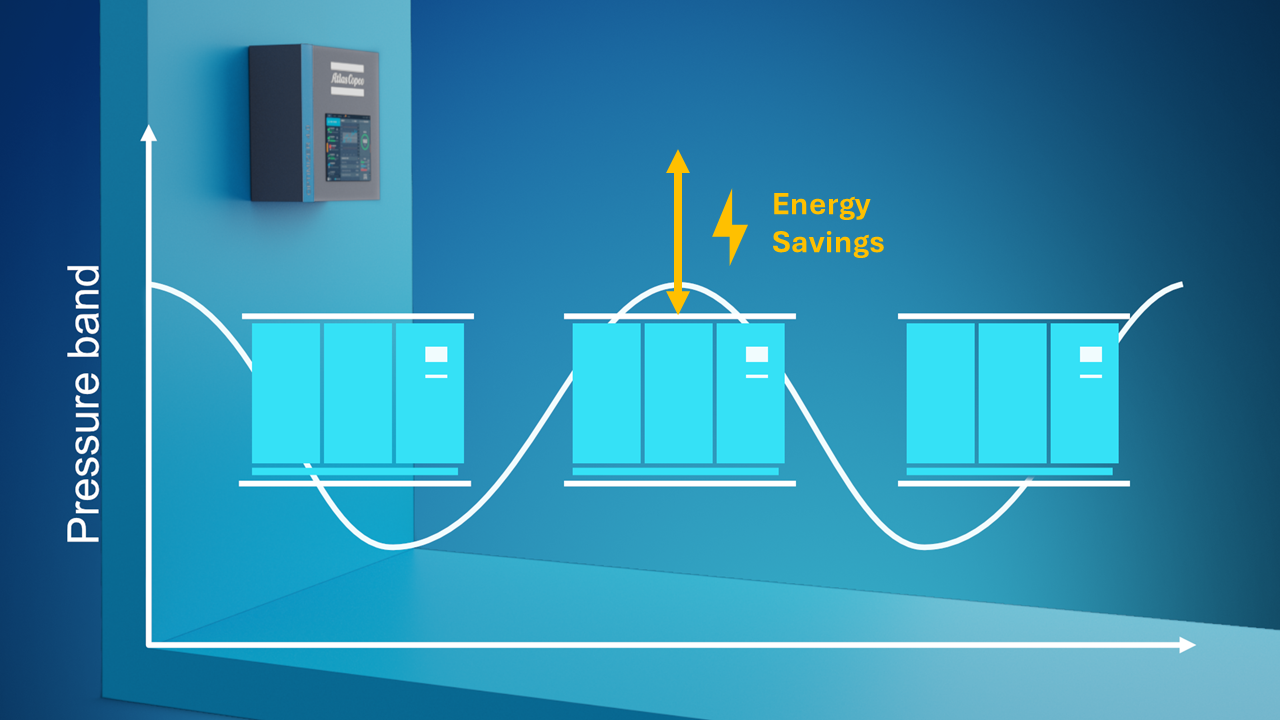

Pressure control

Unlike local control, where individual pressure setpoints are adjusted to ensure cascading, employing a central controller enables a much narrower pressure range. This centralized approach reduces pressure fluctuations and provides a more consistent output pressure for your application.

A tighter, combined pressure band also lowers the operating pressure for each machine:

- Decreasing the pressure by 1 bar(g) (14.5 psi) reduces energy consumption by 7%.

- Lowering the pressure by 1 bar(g) (14.5 psi) cuts air leakages by 13%.

- Pre-programmed pressure bands can be easily switched as needed.

Flow control

Many applications require a variable flow setpoint, such as in aeration or fermentation processes. The Optimizer 4.0 supports managing multiple compressors and blowers for both variable and constant flow control.

- Integrated flow bands maintain the flow within the required demand, helping to reduce energy costs associated with excess airflow.

- Airflow fluctuations are kept to a minimum, even during sudden changes in demand.

- The operation of your VSD or centrifugal compressors and blowers is optimized for efficiency.

3. Control modes

The Optimizer 4.0 offers various control modes depending on the regulation needed. These modes can be combined for a group of compressors and blowers, known as group management.

Energy savings mode

Energy savings mode prioritizes maximizing energy efficiency while maintaining consistent pressure output.

- Load-Unload machines are managed to minimize unload time as much as possible.

- VSD machines are adjusted to operate within the optimal range of their performance curves.

- Centrifugal machines coordinate with other compressors to reduce excess blow-off air.

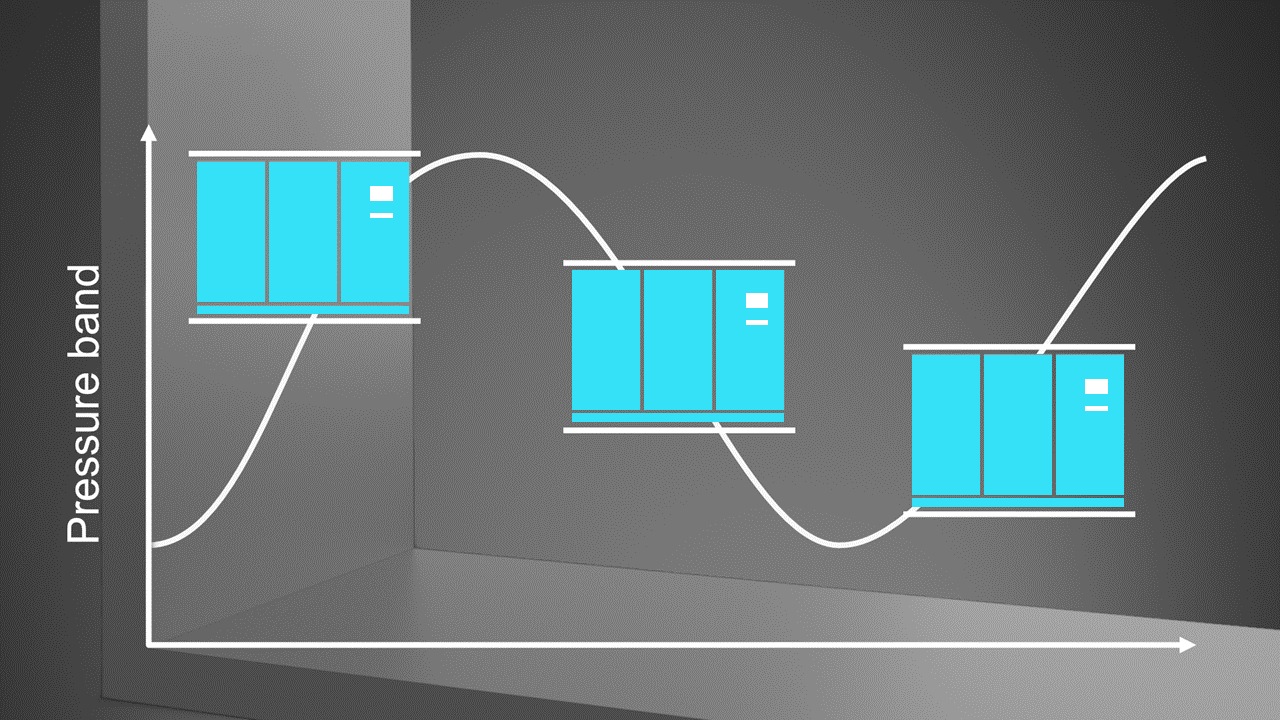

Multiple pressure bands

Atlas Copco central controllers play a key role in enhancing the efficiency of the entire compressed air network.

- The Optimizer 4.0 and Equalizer 4.0 PRO enable the configuration of Multiple Pressure Bands, allowing the air supply to be customized according to production needs. This also helps reduce energy consumption.

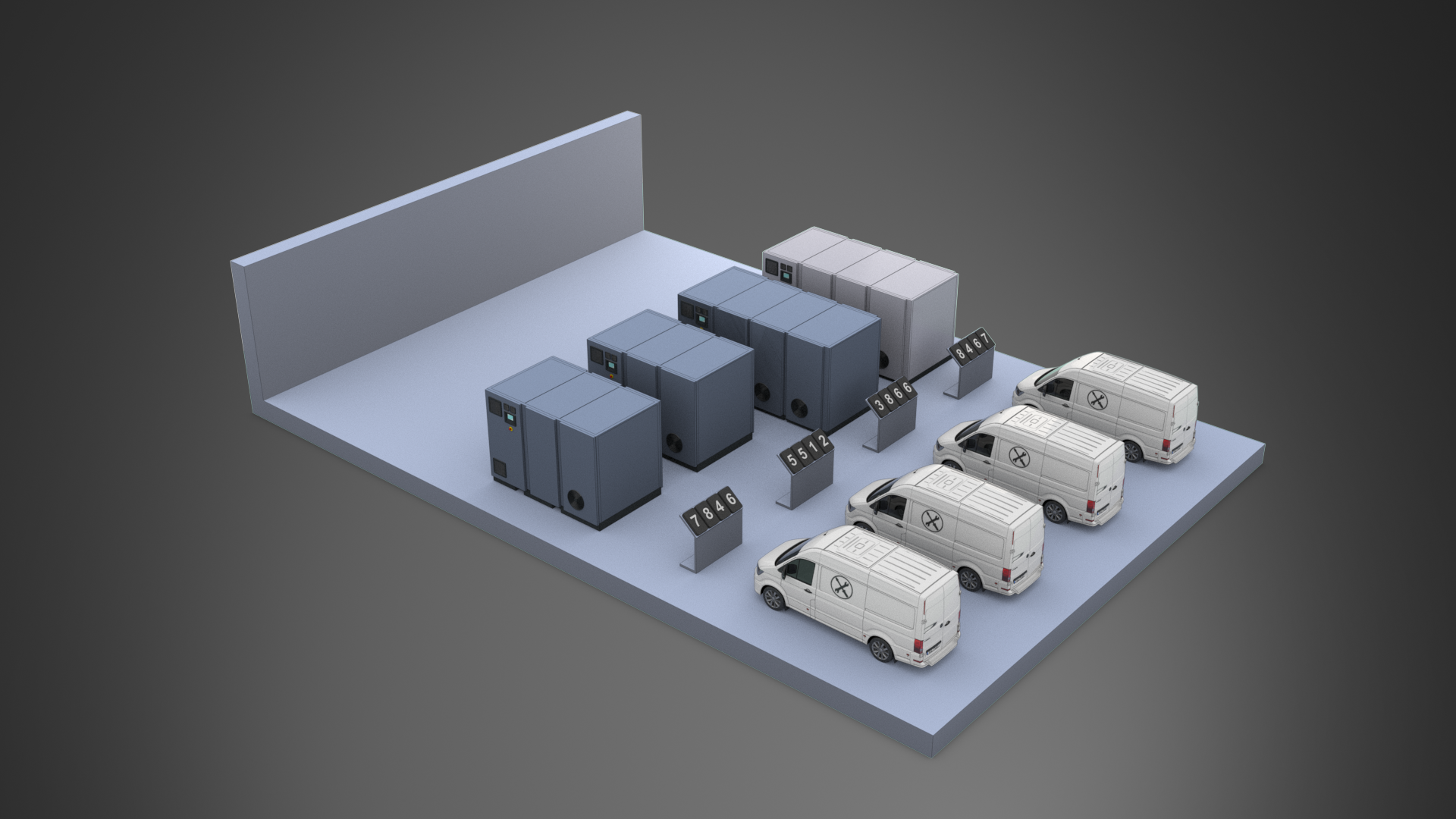

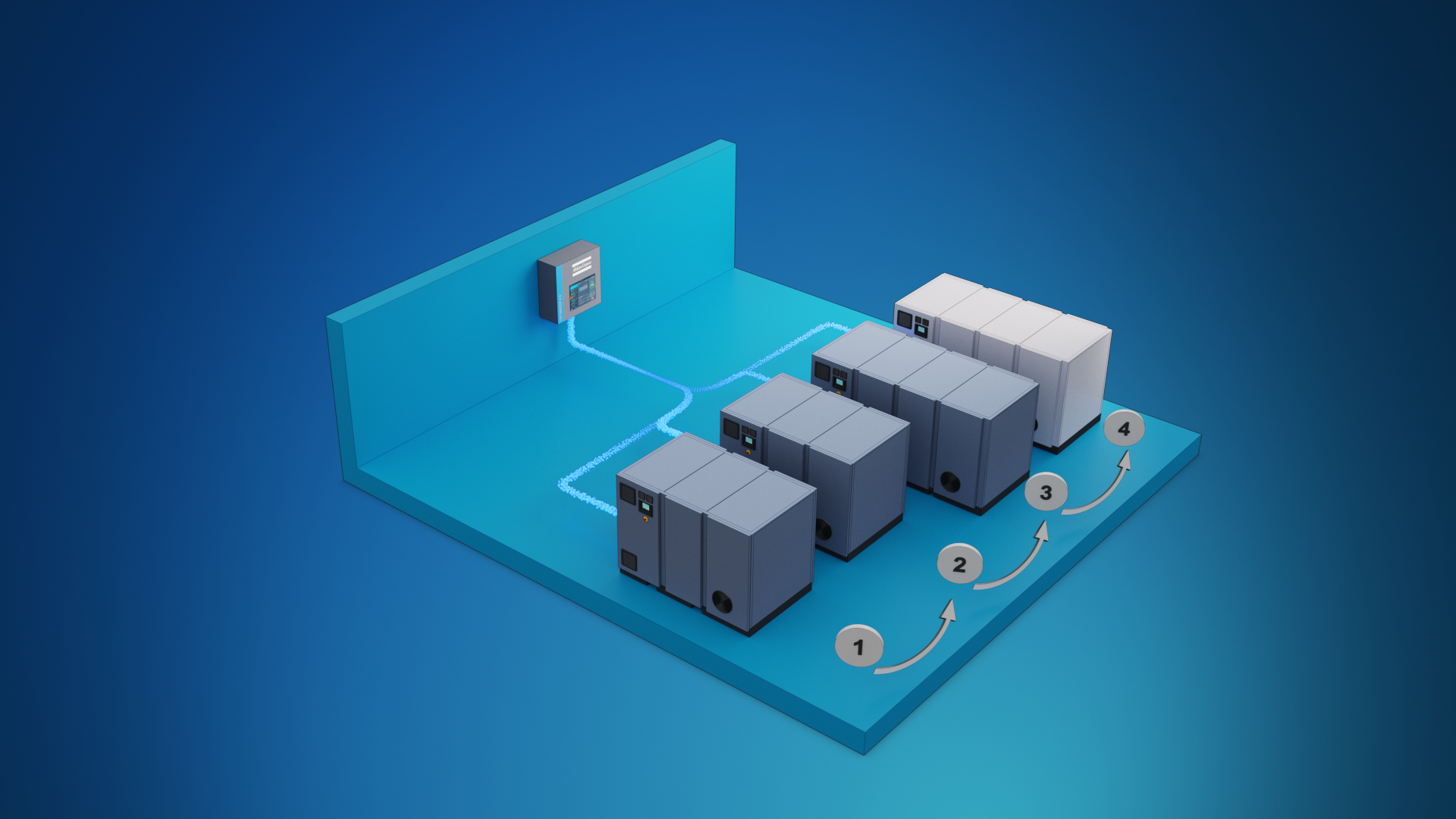

Forced sequence mode

Forced Sequence mode gives the full flexibility to select the order in which the compressors or blowers need to be operated and controlled. For example, you may want to prioritize the operation of newer equipment.

- Easily select the sequencing order.

- Have the full flexibility on how the machines are controlled.

4. Enhance energy savings using artificial intelligence

The Optimizer 4.0 can be upgraded with a Smart subscription, turning it into the Optimizer 4.0 S. This upgraded model improves performance in terms of Saving, Stability, and Service. Further savings are achieved through Dynamic Pressure control and Autotuning, which integrate artificial intelligence into your compressed air system.