In a smart compressed air system, compressors, blowers, dryers, and other equipment maintain a real-time link with Atlas Copco’s central controllers, allowing for ongoing data visualization and supervision.

Intelligent monitoring of your installation

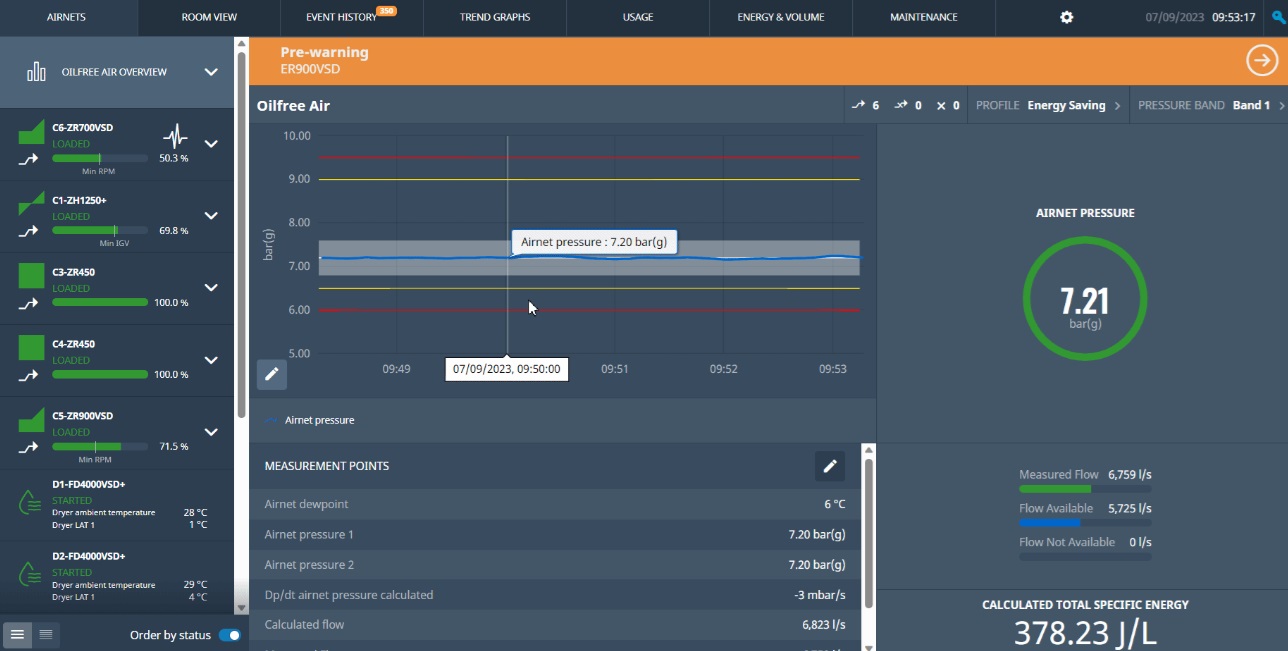

Airnets & event history

This section provides a summary of your installation. From this screen, you can access all essential information regarding your compressed air network or process.

- Quickly view the flow and pressure readings for your airnets and the machines connected to them..

- Conveniently integrate or disconnect machines using the Optimizer 4.0 or Equalizer 4.0 PRO.

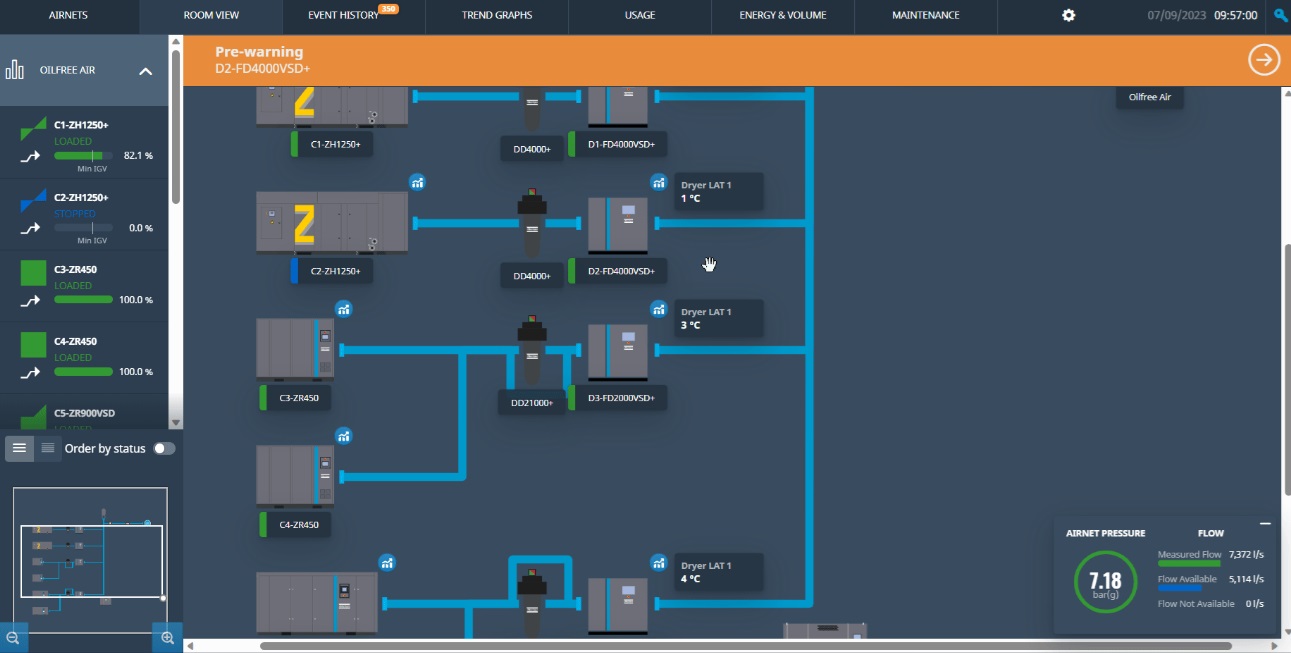

Room view

This SCADA interface provides a clear display of which machines are running, their operational settings, and offers valuable information about consumption.

- A user-friendly and comprehensive overview of your system

- The ability to monitor various measurements and computed values, including data from your own measurement devices.

Trend graphs & maintenance

Create customized trend graphs for the key parameters relevant to your production facility.

- Generate graphs effortlessly using data from machines and the airnet. You can also integrate your own measurement devices, like flow meters, through analogue inputs to monitor those data points.

- Export all collected and calculated data for comprehensive analysis.

- Easily track upcoming services, with the overview clearly showing the next required service type and the number of running hours remaining before it’s due.

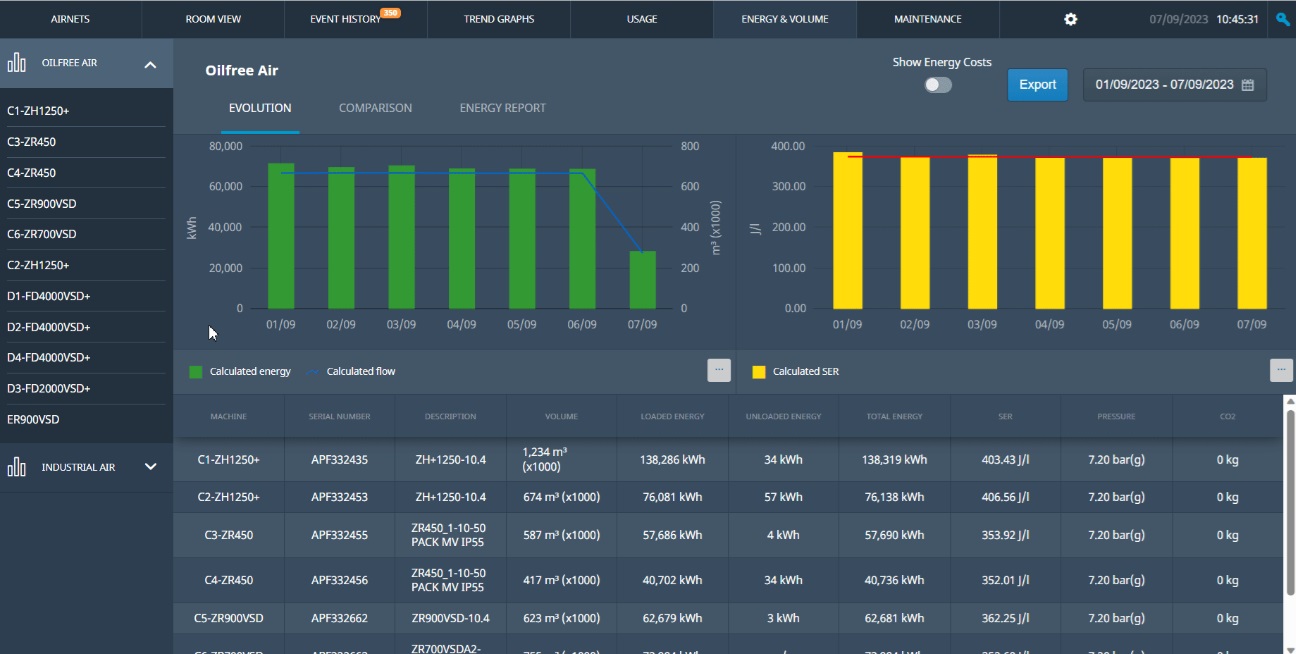

Energy & usage insights

This overview provides comprehensive information on machine parameters, compressed air and flow demand, power consumption, and other alerts accessible remotely through the Local Area Network.

- Transparent details on your installation’s power usage, consumption, and CO2 emissions..

- Energy Report: Conveniently export a detailed report covering a selected timeframe within your production schedule.

- Data logging includes at least 30 days of recorded and calculated data, with energy information stored for up to two years in compliance with ISO50001 standards.

Smart page

- This unique perspective provides additional information regarding the overall performance of your installation.

- Energy savings and CO² reductions are measured against local control benchmarks.

- These savings can be shown not only in standard units but also converted into the corresponding currency.

- Gain further understanding of energy efficiency and operational enhancements happening behind the scenes.

Prepare for the future with connectivity

Once your equipment is enabled for the Internet of Things (IoT), the machines within your compressed air and blower system can collect and transmit data to your facilities management team, allowing for quicker and more customized analysis. All devices and machinery remain linked, constantly transmitting information to a centralized SCADA, DCS, or Cloud platform through a secure LAN network.

Remoteview

Monitoring is not only restricted to the compressor or blower room anymore. REMOTEVIEW mirrors the Optimizer 4.0 and Equalizer 4.0 PRO user interface to any monitoring device through a Local Area Network (LAN). Remote control of the central controller itself is also possible. You are able to change pressure/flow setpoints, integrate & isolate units and select the optimization profile that can done with sufficient access rights.

Smartlink

Get insights and access to compressed air & blower equipment, anytime of the day or anywhere you are through Atlas Copco’s cloud-based monitoring system, SMARTLINK. A customized report on energy efficiency is always ready to be downloaded. Early warning notifications to replace maintenance parts on time avoid unnecessary breakdown and production loss. Besides customer access, SMARTLINK is monitored in key strategic areas around the globe by a dedicated Atlas Copco specialists.

Embedded Gateway

Both the Optimizer 4.0 and Equalizer 4.0 PRO are communication gateways. Via the SMART2SCADA functionality you can easily set up different communication protocols among the central controller and your SCADA/DCS platforms.

- Easily get all the machine and Airnet data from your installation.

- Broad range of embedded Communication Protocols.

- Get and process all the data in your own systems.