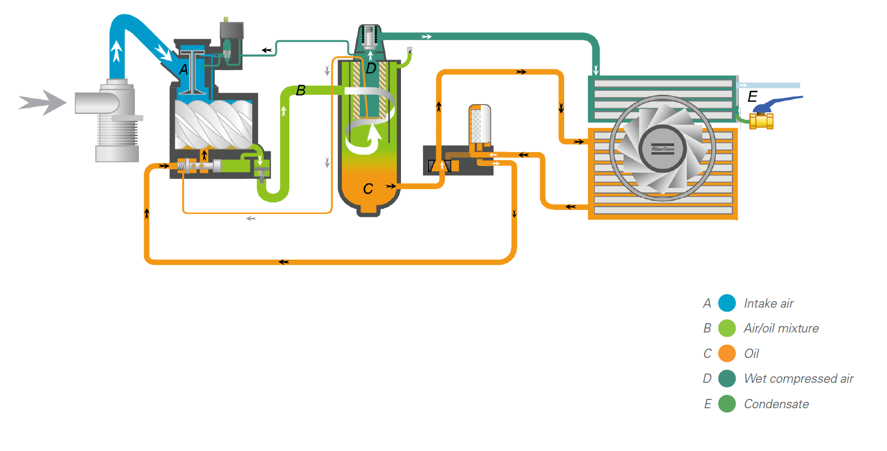

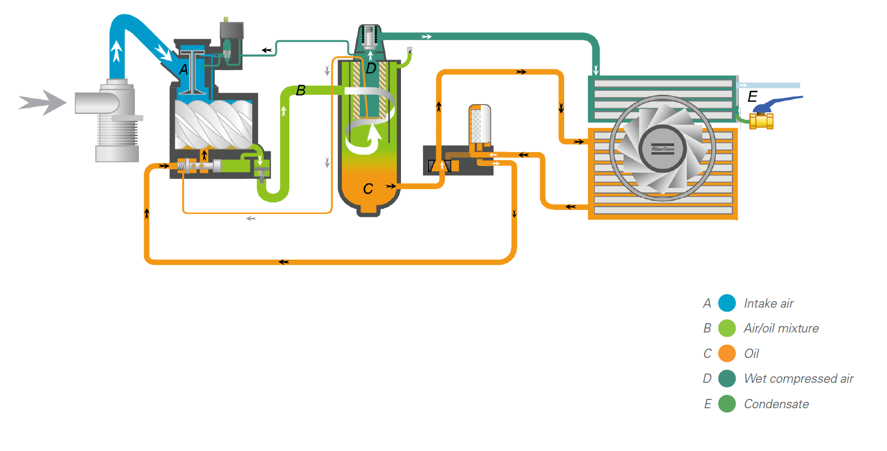

Flowchart

Air & oil flow of the oil-lubricated GA Xtreme compressor.

Air flow

Air enters the compressor through the inlet filter and is compressed in the oil-lubricated screw compressor element which has already passed through the inlet valve.

The lubricating fluid is injected into the air during the compression phase and the air/oil mixture passes from the check valve to the air/oil separator.

The air then passes through the minimum pressure valve and is cooled by an air-cooled aftercooler and the compressed air is delivered to the main pipeline.

Oil

The lubricating fluid contained in the separator (AR), due to the pressure difference, flows through the thermostatic by-pass valve, air-cooled oil cooler, high-efficiency oil filter and oil shut-off valve before being injected into the element. compressor (E) where it cools, seals and lubricates the compression process.

High efficiency filters provide superior filtration compared to conventional filters, resulting in a cleaner lubricant. The thermostatic by-pass valve ensures that the compressor quickly reaches the optimum temperature at start-up and maintains this temperature during the low load period, allowing the cold lubricant to bypass the oil cooler.

The Fan provides cooling air for the oil cooler and aftercooler, ensuring satisfactory operating temperatures.