Engineered for reliability

GG compressors are designed specifically to meet the high demands of biogas upgrading and gas grid applications. Along with maximum efficiency, we prioritized safe handling and reliable generation with the quality you need. Explore the highlights below to find out more.

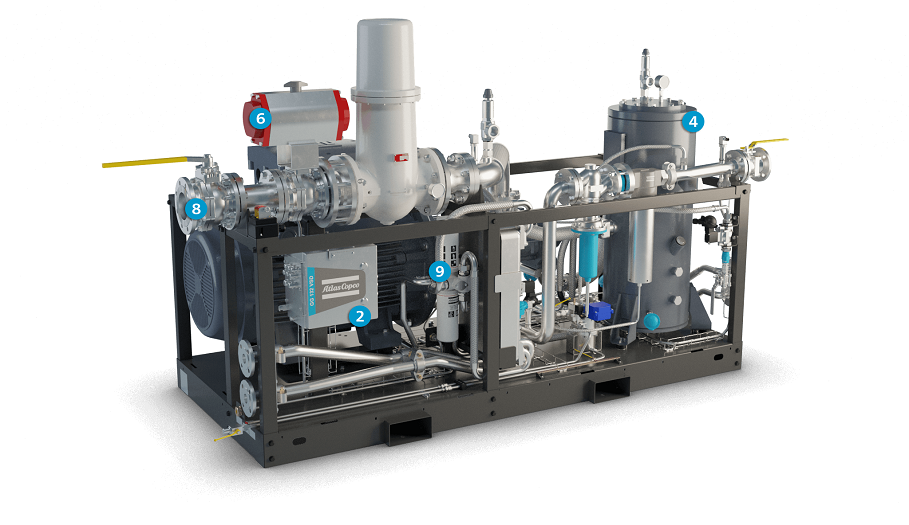

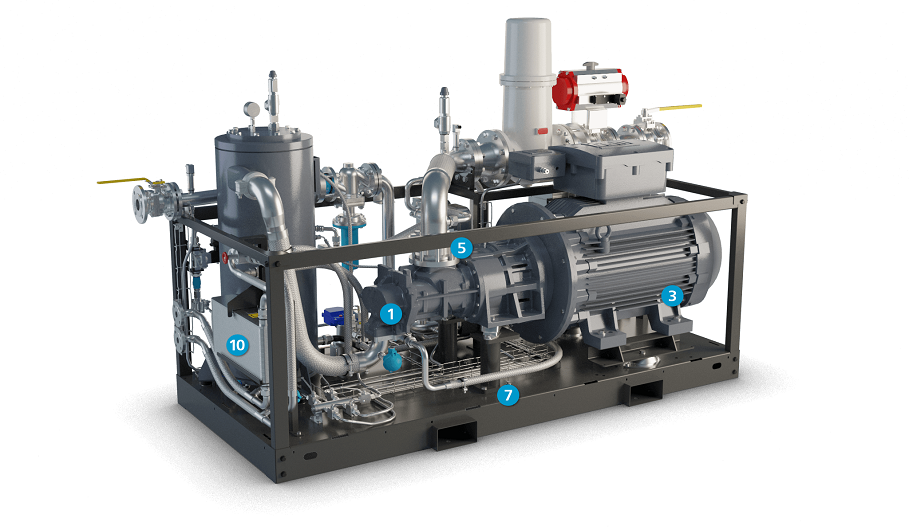

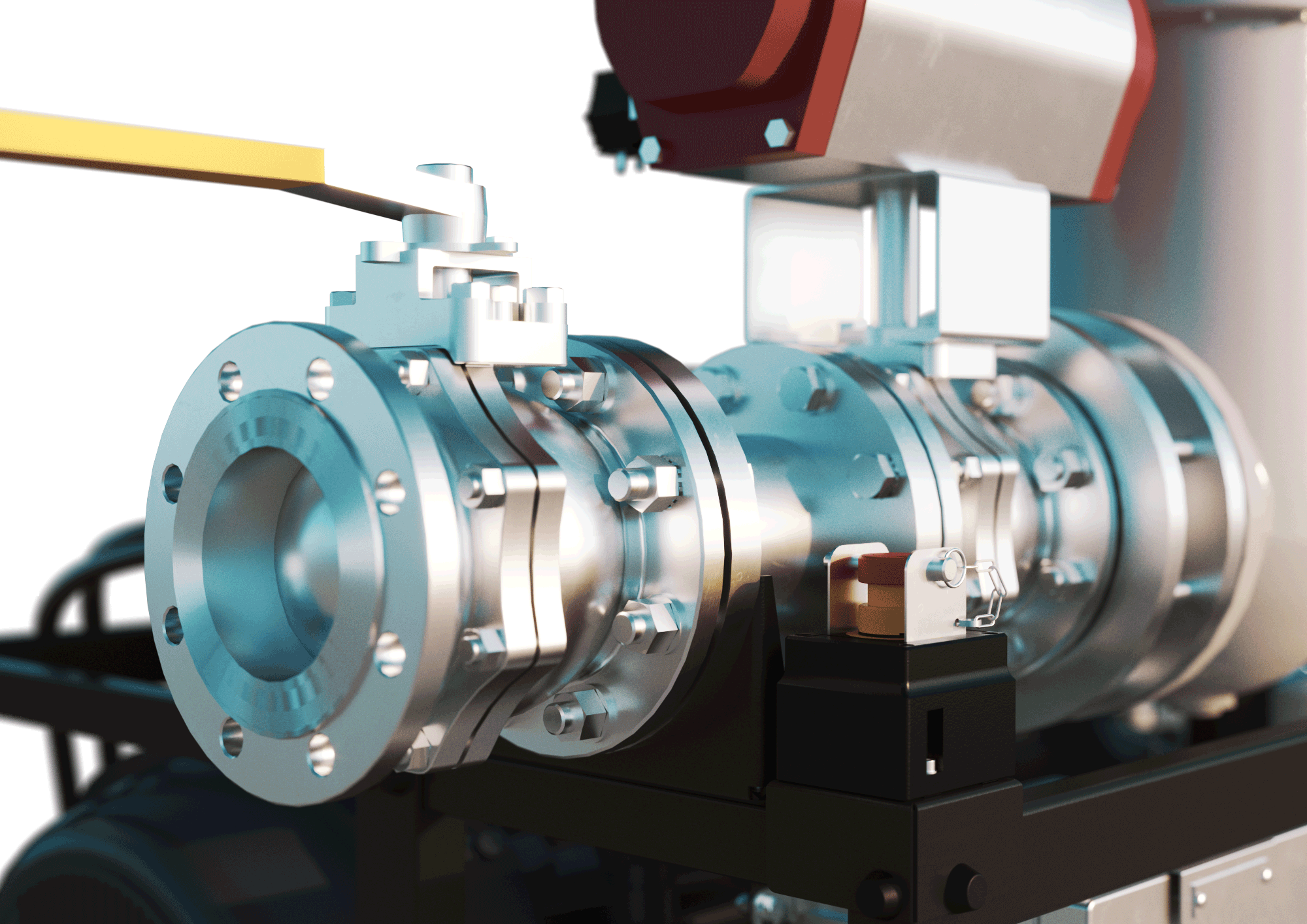

GG oil-lubricated gas screw compressor

Left side

Right side

-

1

High efficiency gas screw

-

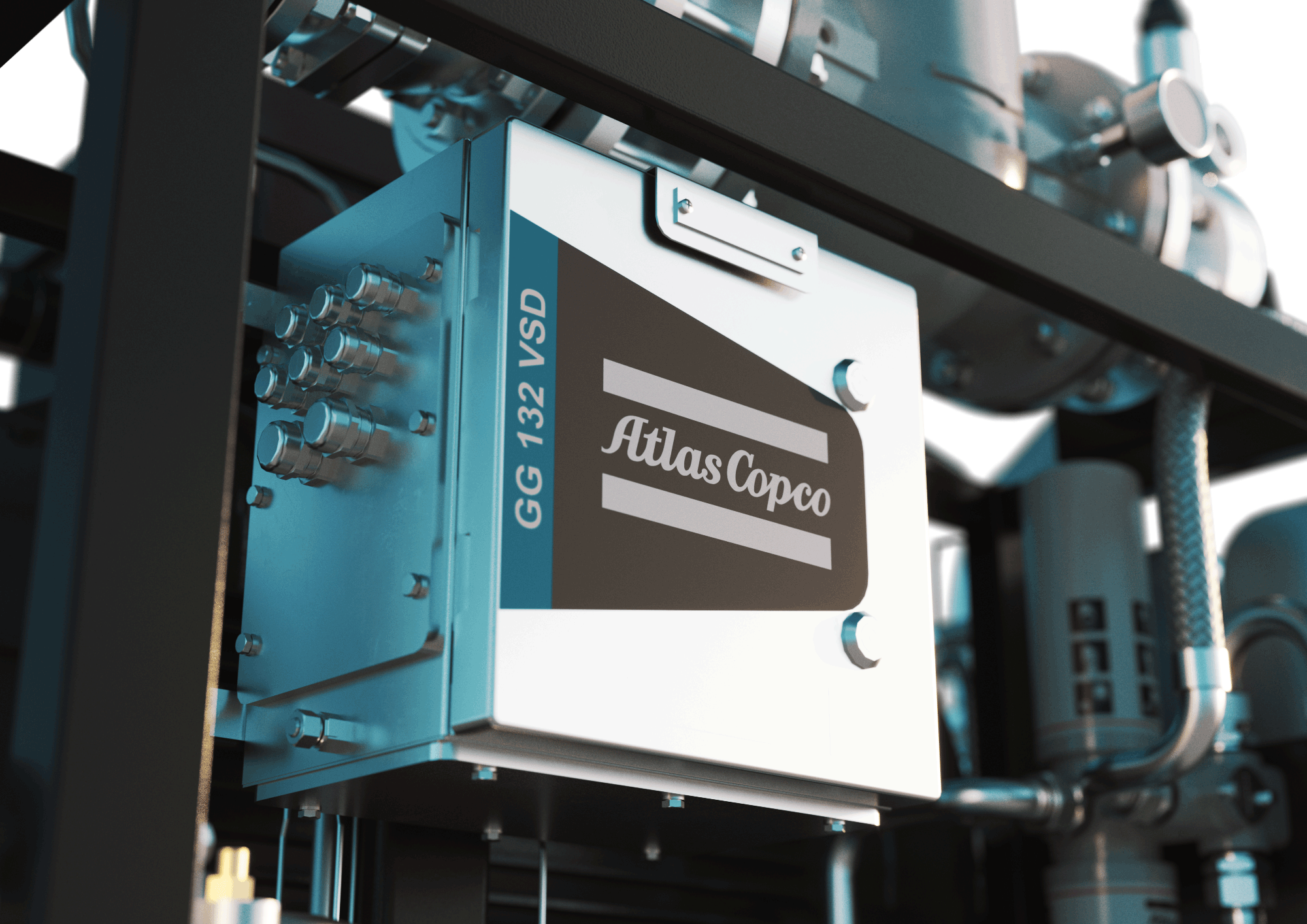

2

Junction box

-

3

Safe electric motor with Variable Speed Drive

-

4

High-performance oil separator

-

5

No back-flow

-

6

Gas inlet valve

-

7

Frame: compact, plug & play

-

8

Integrated inlet gas train

-

9

Oil filter & oil

-

10

Energy recovery

-

1

High efficiency gas screw

Single stage, oil lubricated, with superior mechanical shaft seal.

Rotors maximize gas flow at low energy cost.

-

2

Junction box

Safe, explosion-proof.

Stainless steel enclosure.

Easily accessible connections to control cubicle.

-

3

Safe electric motor with Variable Speed Drive

IP55 – IEC – 400 V/50 Hz – Eexd IIB T4.

Flexible coupling.

-

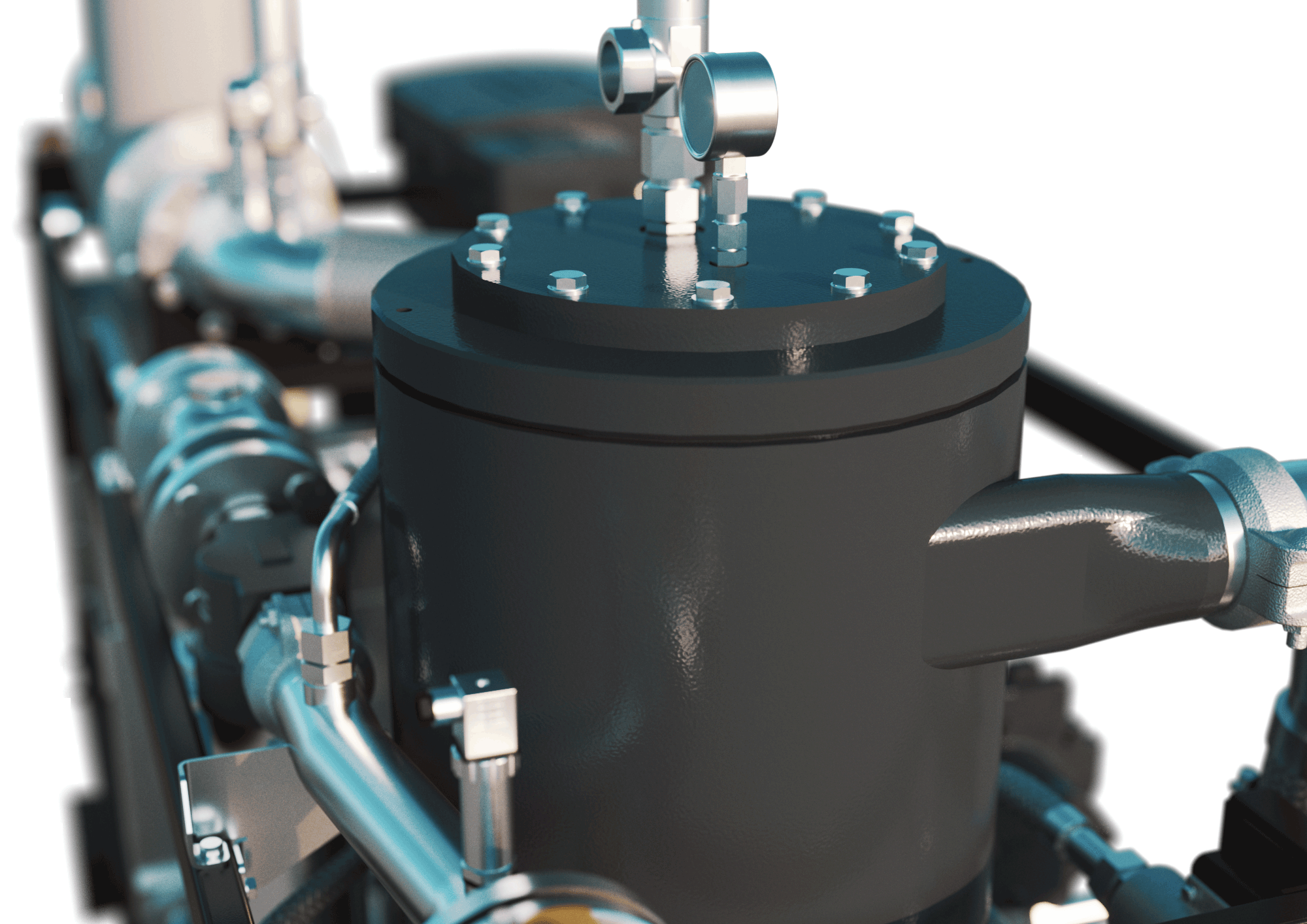

4

High-performance oil separator

Oil residue in gas down to 5 ppm.

Contributes to preserve the components in your gas upgrading process.

Longer interval between oil top-ups reduces maintenance costs.

-

5

No back-flow

Non-return valve prevents risk of back-flow of oil, protecting the gas net.

-

6

Gas inlet valve

Closed on emergency stop, isolating compressor from gas supply.

-

7

Frame: compact, plug & play

All equipment fitted on baseframe.

Cable protection with stainless steel trays.

Slots for forklift handling.

Easily accessible connections for water, gas, and power.

-

8

Integrated inlet gas train

Straightforward connection with easy access for gas inlet valve and optional gas filter.

Gas filter:

High filtration rate (efficiency).

Upstream particle separation.

Replaceable filter cartridges.

-

9

Oil filter & oil

The high efficiency oil filter provides superior filtration compared to conventional filters resulting in cleaner lubricant. The thermostatic bypass valve ensures that the compressor quickly reaches optimum operating temperature and maintains temperature during periods of low load. The lubricant is specifically formulated to provide limited dilution with hydrocarbon gases and features excellent protection against hydrogen sulfide in the gas stream.

-

10

Energy recovery

The energy recovery system consists of a built-in heat exchanger and thermostatically controlled system to recover the heat from the compressor in the form of warm water without any adverse influence on the compressor performance.