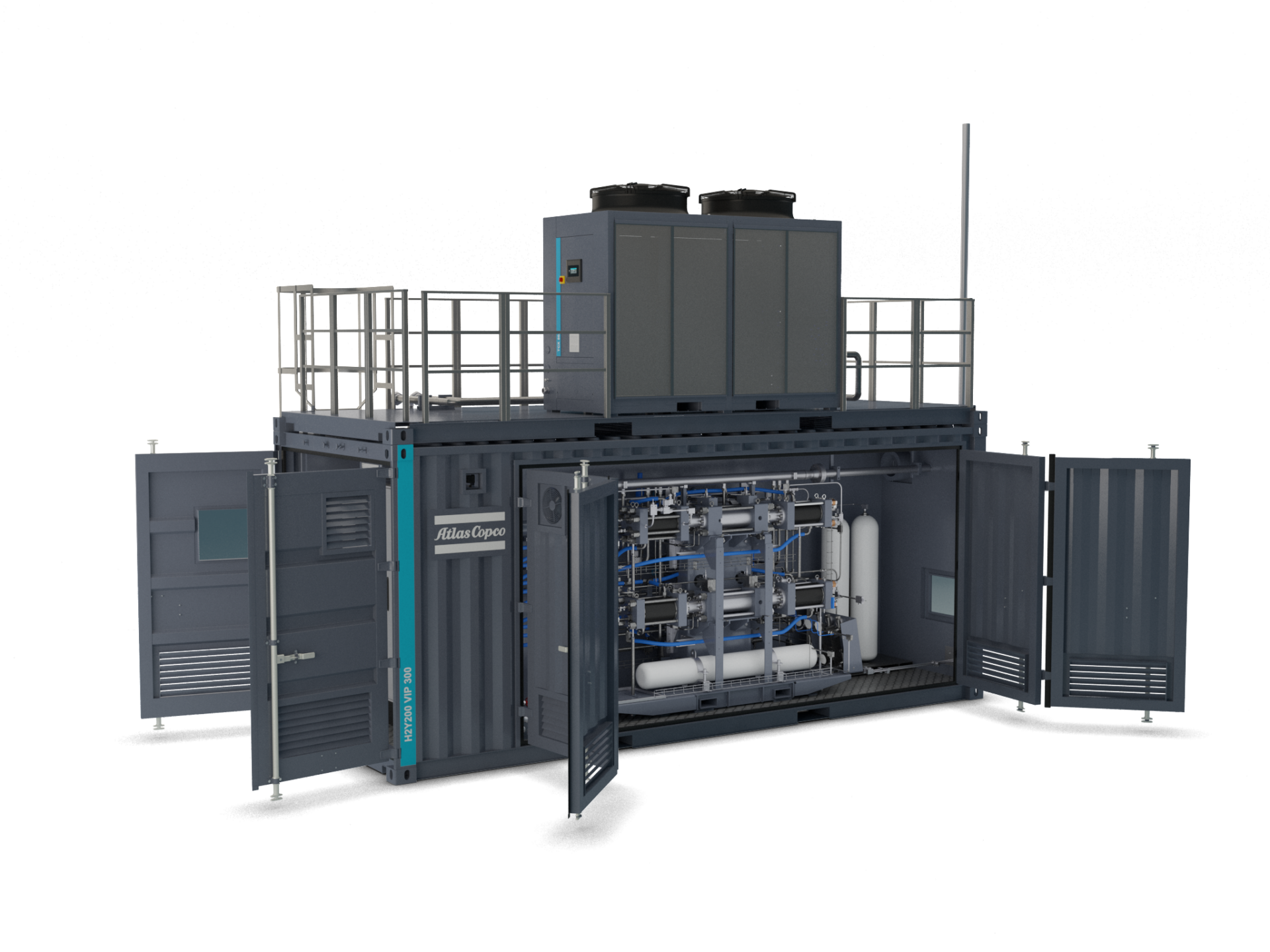

Like all Atlas Copco equipment, H2Y compressors are engineered to deliver exceptional value to our customers. Specifically designed for HRS and trailer filling applications, these compressors integrate essential features and qualities to optimize your setup, ensure reliable output, and drive your business growth.

Innovation for reliability and cost savings

Maximum safety in hydrogen handling

Safety is paramount when dealing with hydrogen. H2Y hydraulic hydrogen compressors are engineered to minimize risks associated with gas leakages, contamination, and other potential hazards. Each compressor package is equipped with advanced safety instrumentation and control loops to enhance reliability and provide peace of mind.

Our hydrogen compressors comply with major international and local safety codes. Each compressor undergoes rigorous testing at our facilities to guarantee optimal performance and safety. These measures reflect our commitment to providing safe and efficient hydrogen handling solutions that protect your operations and personnel.

Pure oil-free hydrogen to protect your HRS operation

Fuel cell operations depend on high quality oil-free hydrogen to avoid risks relating to product spoilage, vehicle failure, downtime, and legal issues. H2Y compressors ensure oil-free compression to maintain gas purity and integrity. Their advanced technologies deliver the hydrogen quality you need to protect your business and meet stringent industry standards.

- Distance pieces equipped with oil sealing rings ensure physical separation between the transmission and the cylinders.

- The length of the piston rod is calculated so that no part in contact with oil enters the compression chamber.

- Packings with sealing rings ensure tightness between the cylinder and distance piece.

Smooth, reliable production with low maintenance

H2Y compressors are designed for 24/7 industrial service, ensuring a smooth and reliable hydrogen supply without constant supervision. With high-quality stainless steel components and minimized noise and vibration, they deliver continuous, dependable, and safe operation. Their low maintenance requirements reduce downtime and help keep costs in check.

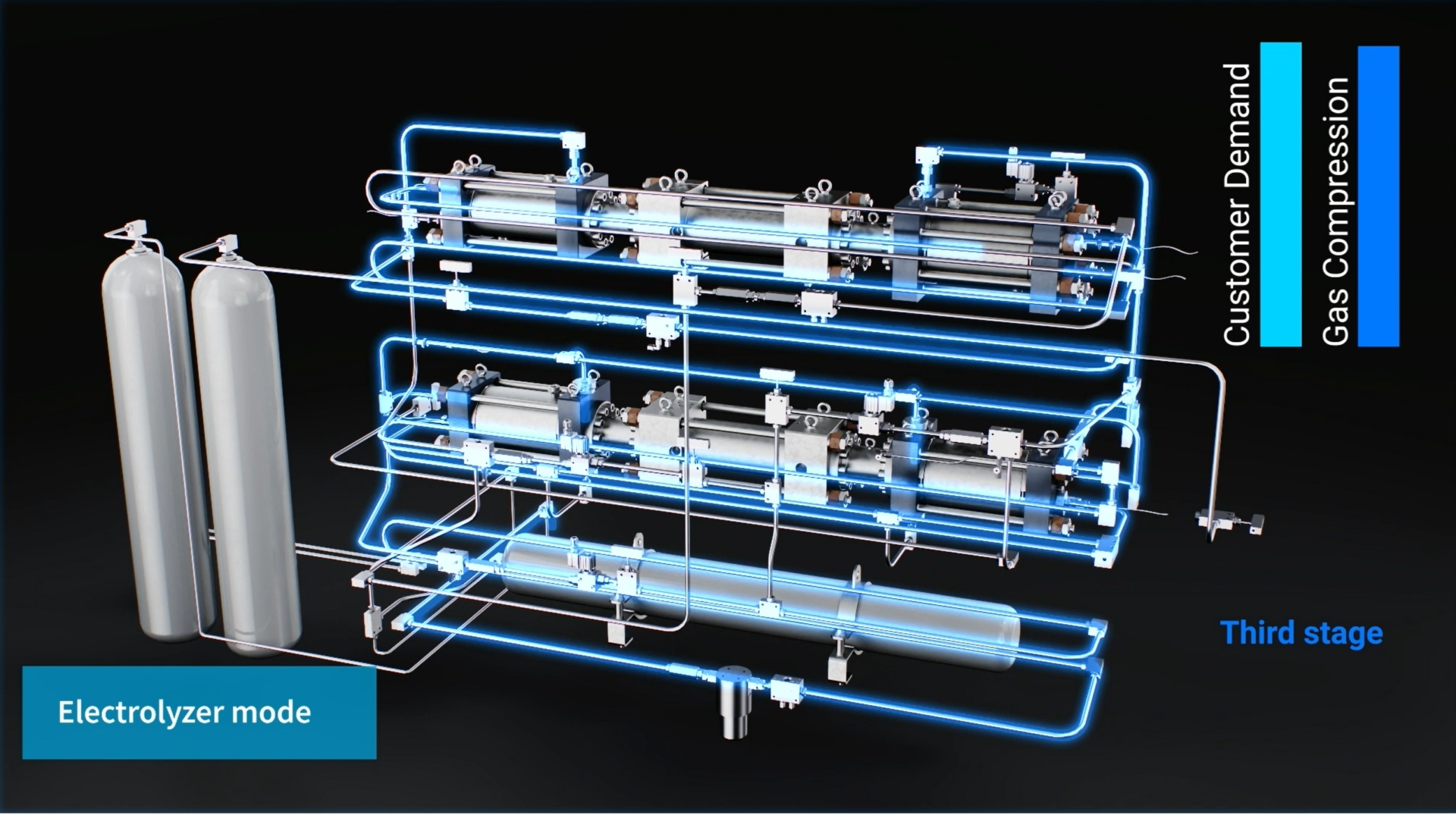

VPP (Variable Piston Pump)

A Variable Piston Pump version is available to maintain a set pressure at the inlet pressure vessel. This advanced technology ensures that the compression rate follows electrolyzer and SMR production rates, helping to drive greater efficiency and sustainability in hydrogen refueling and trailer filling operations.

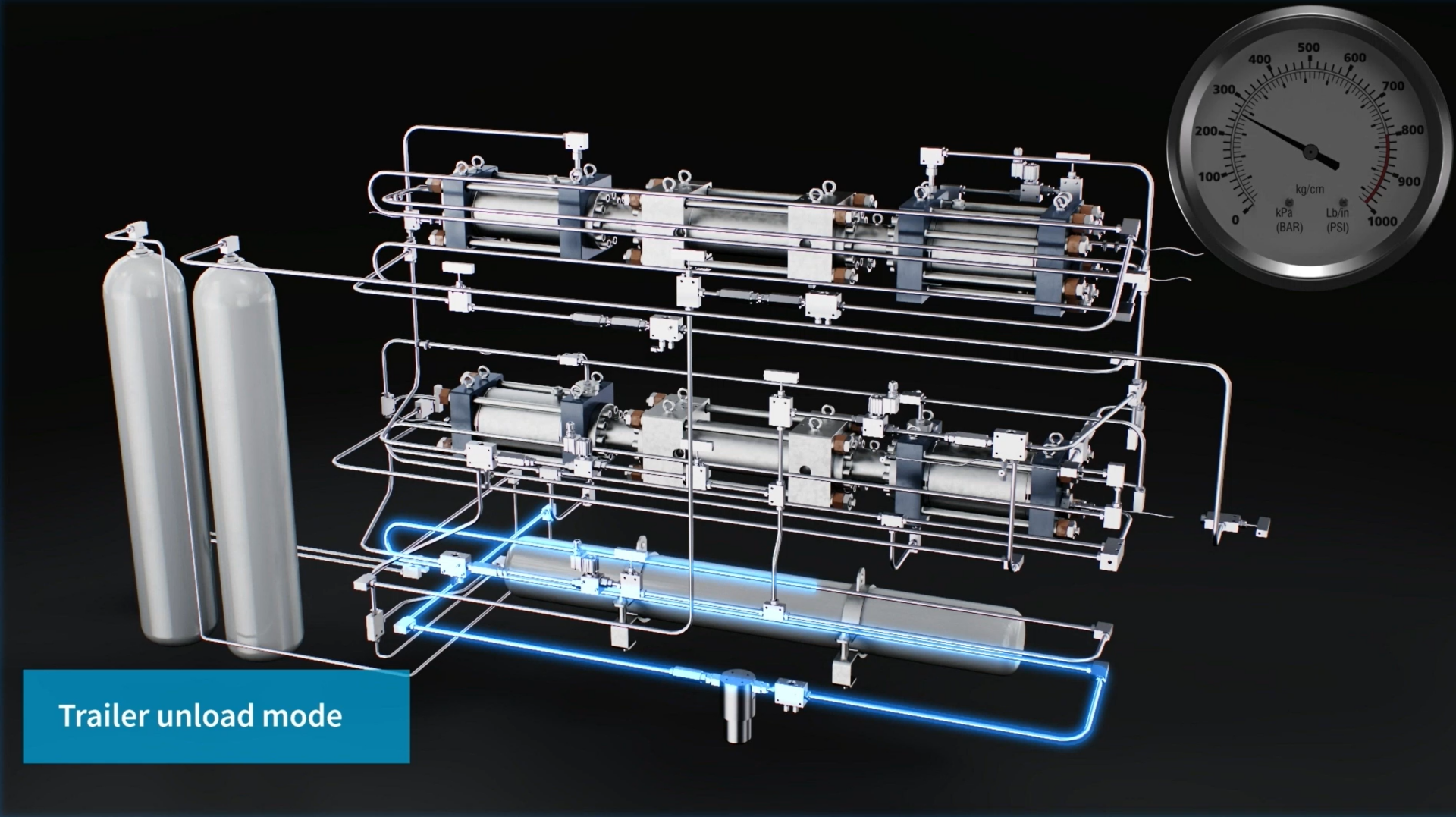

VIP (Variable Inlet Pressure)

H2Y compressors are available in a variable inlet pressure version suitable for trailer unloading. This version adapts to inlet pressures ranging between 300 to 20 bar. When the inlet pressure is high, the gas goes through a single stage of compression. If the inlet pressure drops (e.g. below 170 bar), a second stage of compression is activated. This system ensures consistent peak performance and maximum energy efficiency even when conditions are variable.

A name you can trust in a changing world

The industrial world is evolving fast as we transition towards new energy sources in an effort to meet ever more urgent climate targets. With over 150+ years of experience, Atlas Copco has built an enviable reputation as a master in compression technology. We are passionate about meeting all our customers’ needs, embracing new challenges with expertise, innovation, and outstanding product and component quality. Capably handling a wide variety of gases and gas mixtures, we can tailor our compressors to the specific requirements of your processes.

Always there for you

We care about the reputation of the business you have built. Along with first-class reliability to ensure uninterrupted production, we are committed to excellent service with strong local presence. Our expert teams are always on hand to answer questions, discuss solutions and take care of your servicing and maintenance needs.