The unique modular concept means that H2Y compressors can be installed in a range of systems and combinations. This offers you maximum flexibility as well as the potential to scale up as requirements change.

Smart gas solutions for your process

A constant supply of compressed gas

Fast fill for a range of inlet pressures with constant supply of compressed gas. A reliable hydrogen fueling installation is key, as any downtime of your compressed gas installation will immediately impact your revenue.

From ‘fast fill’, large flow H2 fill station solutions to daughter stations in a virtual pipeline, Atlas Copco protects your hydrogen booster delivery chain with efficient, reliable, and safe solutions. Our containerized Plug & Play units are factory tested to ensure a long lifetime of trouble-free operation and 100% oil-free compressed hydrogen.

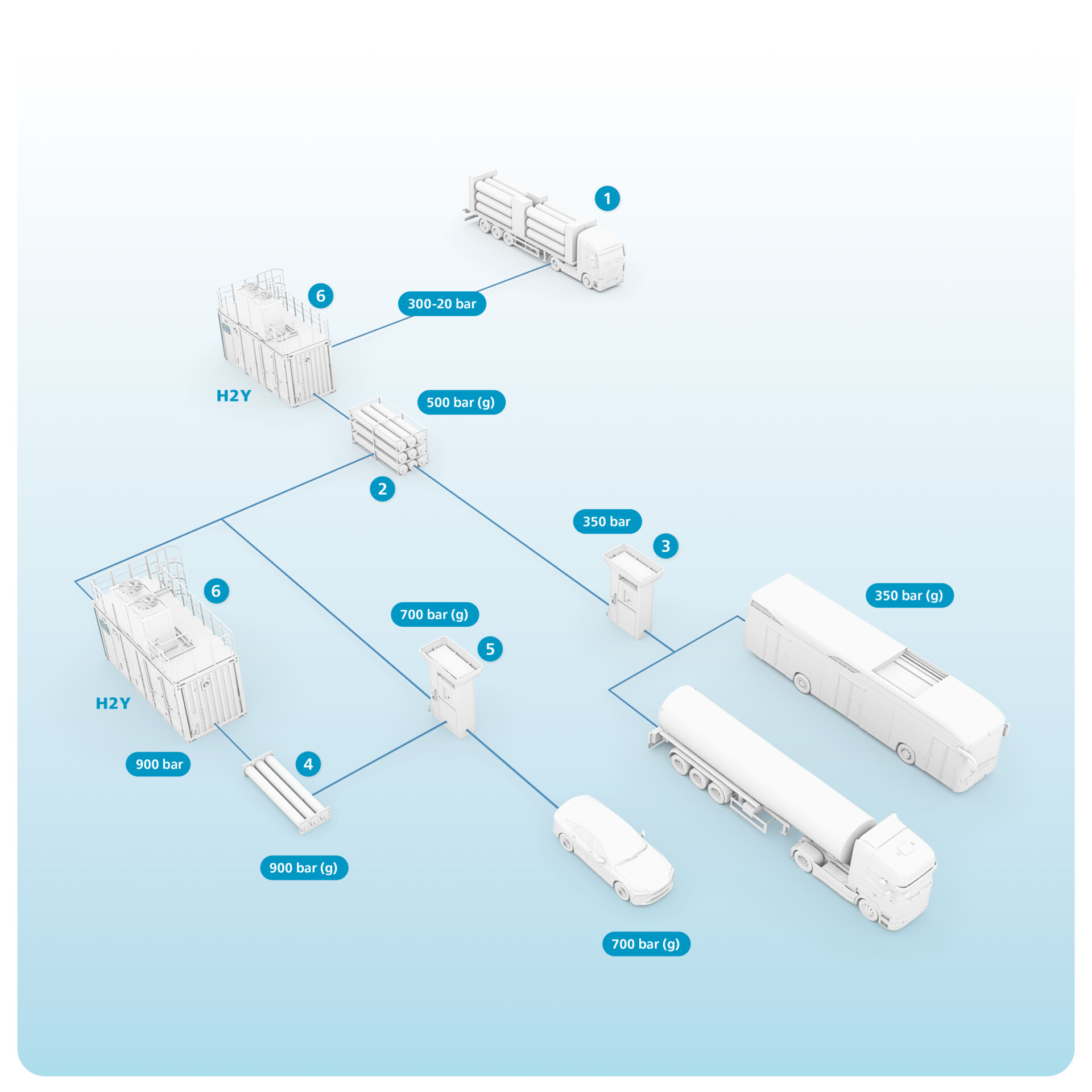

Mother and daughter hydrogen stations

When operating a virtual gas pipeline from the supply line to a daughter station, the focus is on speed and efficiency. Our systems are designed to achieve this by minimizing pressure losses and ensuring the same high efficiency as you would expect when filling directly from a supply line. H2Y hydraulic compressor packages for daughter stations support the virtual pipeline segment by:

- eliminating the need for an external PRV (they accept variable inlet pressures from 300 bar to 20 bar)

- decreasing trailer unloading time by managing high inlet pressures and flows

- significantly reducing energy consumption by automatically adjusting to possible variations in inlet pressure, preventing pressure losses through regulators

- maintaining a constant flow rate

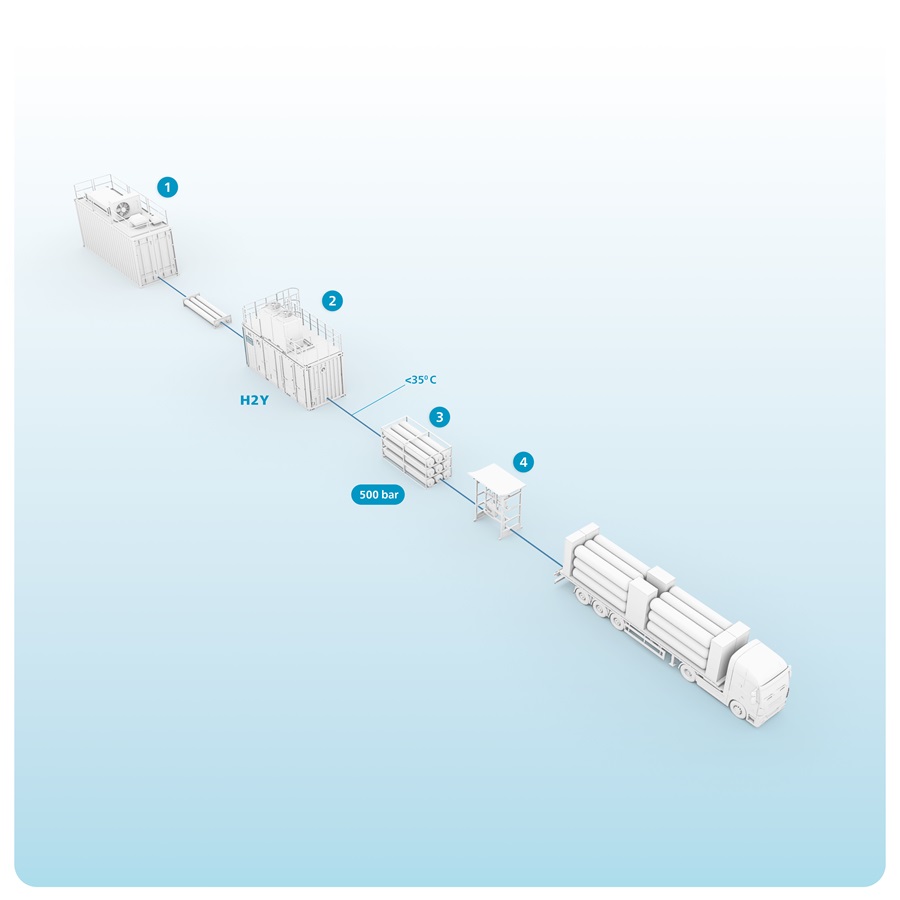

Mother station to truck (VPP)

Daughter station from truck (VIP)

1. Electrolyzer

2. Atlas Copco H2Y

3. Medium pressure storage

4. Filling panel

1. Trailer storage

2. Medium pressure storage

3. Dispenser

4. High pressure storage

5. Dispenser

6. Atlas Copco H2Y