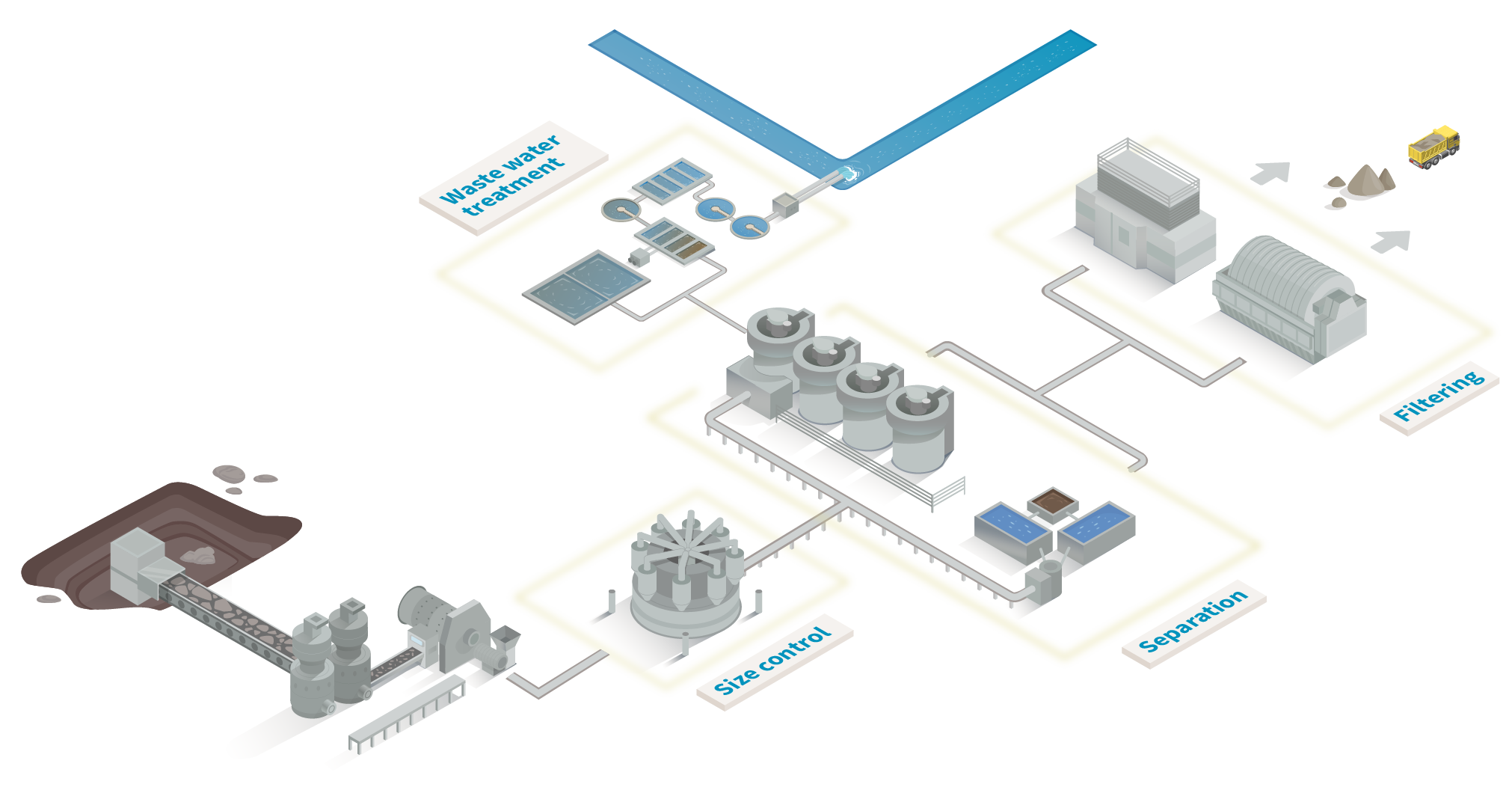

Mine

The production of metals starts with the extraction of raw materials, also called ores, from a mine containing the valuable metals. These can be in either open-pit (most common) or closed-pit mines.

In open-pit mines this is done by blasting while for closed-pit mines this can be done by a combination of blasting and drilling. Today, open-pit mines are the most common.

The ores extracted can have dimensions up to one meter and the concentration on valuable minerals and metals depends on the type of metal explored. Extracted ores are transported to the crusher at the mining plant to start further processing.

Compressed air applications involved at this stage are mainly portable air applications as pneumatic tools, drilling and instrumentation air & utilities.

Crushing

The ores extracted in the extraction phase contain the valuable materials that we want to obtain.

At this stage the minerals cannot be separated yet out of the ore as these are still trapped in gangue or waste material. To allow separation of the useful material (minerals) from the useless material (gangue) the material needs to be crushed to liberation size. Most of the times this takes place in multiple steps by multiple crushers whereby the crusher gap reduces downstream.

Liberation size is the size whereby the valuable materials can be easily separated from the gangue material in the later production steps and typically has dimensions from 5 to 20mm.

At this stage the concentration of the material does not change compared to the initial raw material extracted.

Compressed air applications to be found at this stage are crush bar setting and dust bag filter purge to clean the filters that are collecting the dust generated in the crushers.

Grinding

Grinding is the second step of size reduction and pulverizes the ore up to dimensions of 10 to 75µm.

Grinding is done in a tumbling mill and can be differentiated

- Grinding in dry (powder) or wet condition (slurry).

- Grinding by the material itself (AG mill) or by metal balls in the mill (ball mill) or by both (SAG mill).

At this stage the concentration of the material does not change compared to the initial raw material.

Grinding in dry condition generates a lot of dust which often is collected in dust bags. These bags need to be emptied regularly by dust bag filter purge.

When grinding is done in wet condition then the dust is trapped in the slurry and no specific dust bag is required.

Hydrocyclones

A requirement for the separation phase, is a constant particle size so separation of valuable and gangue materials can be done under stable conditions. Size control of these particles takes place after grinding and before separation.

During size control the slurry typically goes through two hydrocyclones to seperate too large particles from particles with the right size.

In the first hydrocyclone too large and heavy particles are separated from the particles with right size and weight and guided back to the mill via the underflow.

The particles with the right characteristics go with the overflow to the second hydrocyclone and finally to the next production step.

In this production step the concentration of the ore remains unchanged as there takes no separation place between valuable metals and gangue materials.

No or limited compressed air is used at this production step.

Leaching

Leaching is a chemical separation process used to dissolve minerals from the extracted ores and is another separation process next to flotation.

The leaching type used depends on the ore type and concentration, but leaching has two main types where compressed air is used:

- Heap leaching

In heap leaching the ores are stored outdoor on a pile and sprayed with an acid (e.g. cyanide).

Air is blown in a continuous operation through the piled ores to improve the interaction between the acid and the ores. Low pressure equipment typically used for this application is ZM. - Tank leaching

The ores are stored in a tank and sprayed with an acid (e.g. cyanide). An aeration process is again used to improve the interaction between the acid and the ores and typically a ZM is in continuous operation is used for this. The acid and other additives as for example lime required for the process are often delivered to the process through pneumatic conveying.

Flotation

Flotation is probably the most famous compressed air application in the enrichment process of metallic minerals. Flotation is a physical separation process that makes use of the differences in hydrophobicity of materials to separate valuable minerals and gangue materials from each other so a concentrate, containing the valuable minerals, is created.

In flotation the slurry is feed into a tank and agents are added into the tank to change the hydrophobic characteristics of the materials in the tank.

Air is blown at the bottom of the tank is creating bubbles going to the top of the tank.

The valuable minerals, having hydrophobic characteristics attach, to the air bubbles and go to the top of the tank where these create a concentrate or froth containing approximately 20% of valuable metals.

The gangue material, having hydrophilic characteristics, do not attach to the air bubbles and will go to the bottom of the tank where these will create tailings.

Different types of flotation usually require different types of compressed air as there are some differences in the process:

- Froth flotation: 0.5 to 1.5 bar(g) and blowers used can be ZM, ZS and ZB.

- Concord flotation: 1.35 to 2.5 bar(g) and low pressure screw compressors ZE/A can be used for this application.

- Column flotation: have a higher height requiring pressures up to 6.5bar(g), typically oil-injected screw GA are used for this type of flotation.

Disc filter

Disc filtering is an upgrading technique used to reduce the humidity of the concentrate.

Decreasing the humidity and limiting the amount of moisture in the concentrate limits shipment of useless material to the next production steps as refining.

To reduce the moisture content, a rotating disc is submerged in the slurry containing the valuable materials. The slurry is sucked on the disc by use of a vacuum and is subsequently captured and dried on the disc. In this way a cake gets formed.

To collect the cake containing the valuable materials the cake needs to be released from the disc. To achieve this, low pressure compressed air is used to blow off the cake from the disc. Typically, a low pressure screw compressor ZE/A at 3bar(g) running in a discontinuous operation is used for this application.

Filter press

Filter press is an upgrading technique used to reduce the humidity of the concentrate.

Decreasing the humidity and limiting the amount of moisture in the concentrate limits shipment of useless material to the next production steps as refining.

In a first step the slurry is fed into a mold. Once the mold is completely filled a diaphragm is inflated with compressed air to squeeze and remove as much as possible moisture out of the slurry.

In a second step the slurry gets dried by blowing air between the solids and diaphragm, so the moisture level gets further reduced and is creating a cake of required valuable materials.

At the end of the process the mold opens, and the cake gets discharged.

Compressed air at 8 to 16bar, dependent on the installation, is used for all compressed air requirements for this application. Typically, oil-injected screw GA or oil-free screw ZR/T can be used for this application.

Transport to refining

Once extracted and processed at the mine site, the concentrate—rich in valuable minerals—is securely loaded for transport to the refinery plant. Depending on geography and infrastructure, this journey may involve trucks, railcars, or conveyor systems. Throughout the route, careful attention is given to minimizing loss, contamination, and environmental impact. Upon arrival, the concentrate undergoes further refining processes to extract the target metals, turning raw potential into refined industrial-grade materials.

Lagoon

Lagoon systems are commonly used in mining sites to treat wastewater generated from mineral processing and site operations. These engineered basins allow for the natural and assisted breakdown of contaminants through sedimentation, biological activity, and sometimes chemical treatment.

Typically, wastewater flows into a series of lagoons where solids settle out, and microorganisms help degrade organic and inorganic pollutants. Aeration systems may be used to enhance oxygen levels, accelerating treatment efficiency. The final effluent—treated to meet environmental discharge standards—is either reused on-site, such as for dust suppression, or safely released into surrounding environments.

Aeration

Biological aeration is a process that uses oxygen-loving (aerobic) microorganisms to break down organic pollutants in wastewater. It’s widely applied in mining sites to treat effluents from processing plants, camps, and other facilities.

The treatment generally involves:

- Aeration Tanks: Oxygen is supplied—often through diffused aeration systems—to stimulate microbial activity. These microbes metabolize organic matter, reducing contaminants like BOD (biological oxygen demand).

- Biological Activity: A diverse community of aerobic bacteria digests dissolved and suspended waste material. This results in cleaner water and the formation of biomass (activated sludge).

- Clarification Stage: After treatment, water flows into settling tanks or clarifiers where solids and sludge are separated from the treated effluent.

- Sludge Handling: Some sludge is recycled to maintain a stable microbial population; the rest is removed and handled according to environmental protocols.