Did you know that compressed air generation amounts to over 60% of a plant’s total electricity bill? And that energy consumption can account for over 90% of a blower’s lifecycle cost? With Atlas Copco’s new generation of ZB magnetic turbo blower, it helps businesses reduce energy consumption and increase their profits.

Design & control algorithms for optimal efficiency

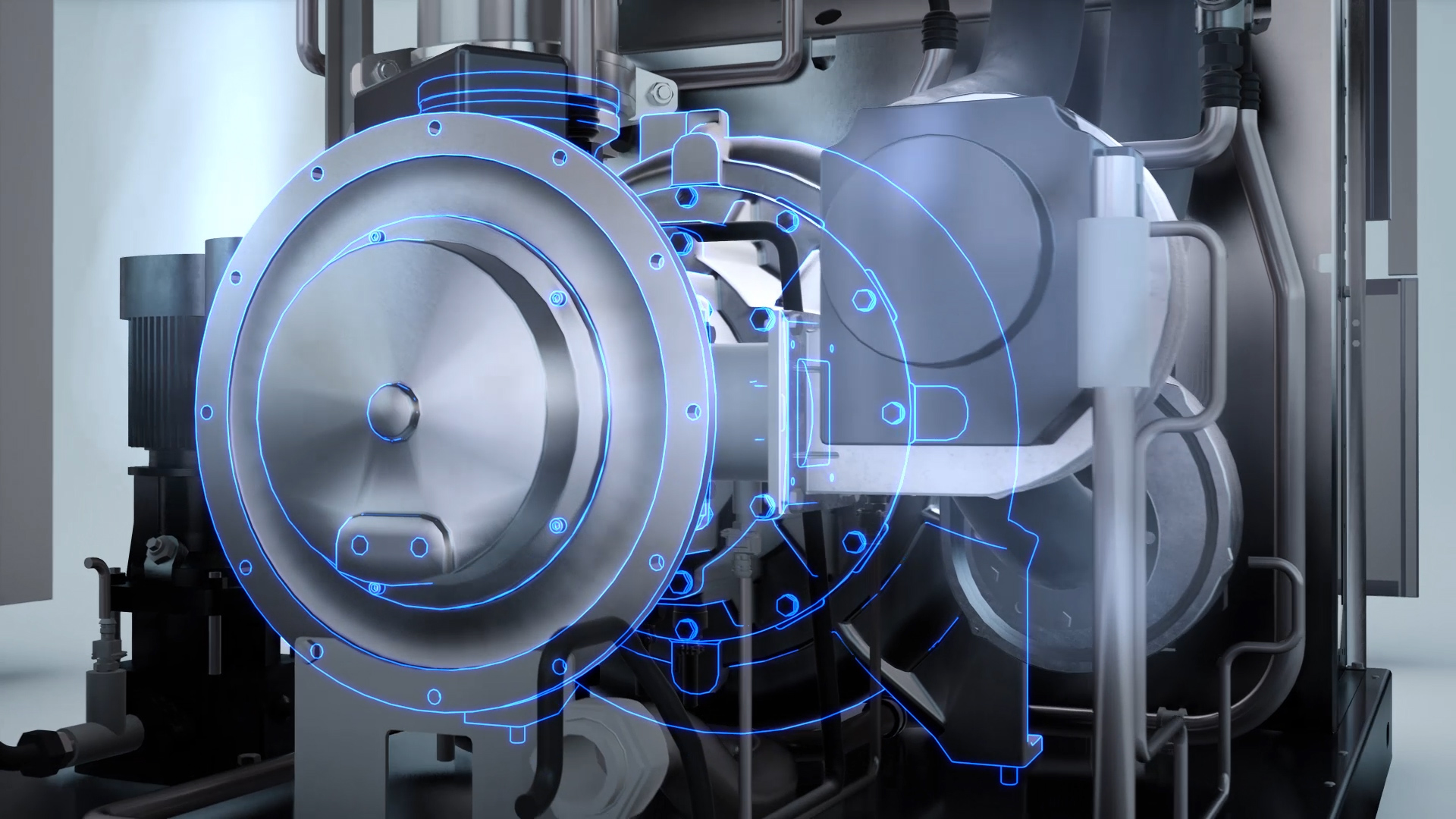

• Magnetic bearing technology for high efficiency operation without any physical contact means no mechanical friction or wear

• Direct connection of the impeller and motor, minimize the loss compared to conventional gear or belt drive.

• Premium labyrinth seal reducing leakages and energy losses over the compression stage

Optimal cooling

Heat is a component’s biggest enemy. It not only affects the lifetime but also the efficiency of the component. With the combination of both air cooling and water cooling, we offer you a high power range within one of the most compact and reliable designs. All key components (from the motor to the magnetic bearings) are operating at a low temperature, extending their lifetime compared to the typical existing cooling systems in the market. Both cooling systems are working independently from each other and from the external conditional fluctuations, making the module’s internal temperature to be maintained constant at any conditions. The thermostatic valve together with the VSD driven cooler fan ensure that the cooling water of the motor and main frequency inverter reach an optimal temperature. By setting the temperature of the cooling water to an exact level, we optimize the efficiency and reliability of the motor and frequency inverter.

Choosing the right impeller design

The impeller type material is crucial in defining the turndown and efficiency of your unit. The material, weight and shape (e.g. back leaning) of the impeller define the efficiency of the airflow and the power needed. E.g. a rough surface will cause more turbulence whilst a heavy impeller requires more power, making it less efficient. By offering a broad range of backward leaning impeller types with a dedicated design for each flow and pressure variant, our specialists can always offer you the most energy efficient solution for your application.

IE 5 motor

All our units are equipped with motors reaching the IE 5 level. The IE 5 (International Efficiency 5) refers to a recognized and international standardized classification. The high IE 5 level of our motors helps to further reduce the energy consumption of the blower.