Discover the different ways to control and monitor your unit

Visual monitoring & control of each unit

Elektronikon Mk5

The full color display gives you an easy-to-understand readout of the equipment’s running conditions.

- Clear icons and intuitive navigation provides you fast access to all of the important settings and data.

- Monitoring of the equipment running conditions and maintenance status; bringing this information to your attention when needed.

- Operation of the equipment to deliver specifically and reliably to your compressed air needs.

- Built-in remote control- and notification functions provided as standard, including simple to use integrated webpage.

- Support for 31 different languages, including character based languages.

Active control from start to end

Magnetic bearings are present to levitate the shaft but also to adjust its position. Sensors are located in three dimensions to measure the shaft’s position. This information is sent to the controller which will adjust the shaft’s position if needed by moving the magnetic force from one direction to another.

- In the starting phase, the shaft is levitated first. It avoids for the shaft to be rubbed to any part of the bearing, reducing its liftime as it’s the case with other turbo technologies.

- Once levitated, the shaft starts to spin until it reaches its targeted speed.

- To stop the shaft from spinning, the unit controller automatically brings it to a standstill position. After this, the shafts lands onto the back-up bearings which are mounted on damping material to soften this transition.

Controlling multiple units

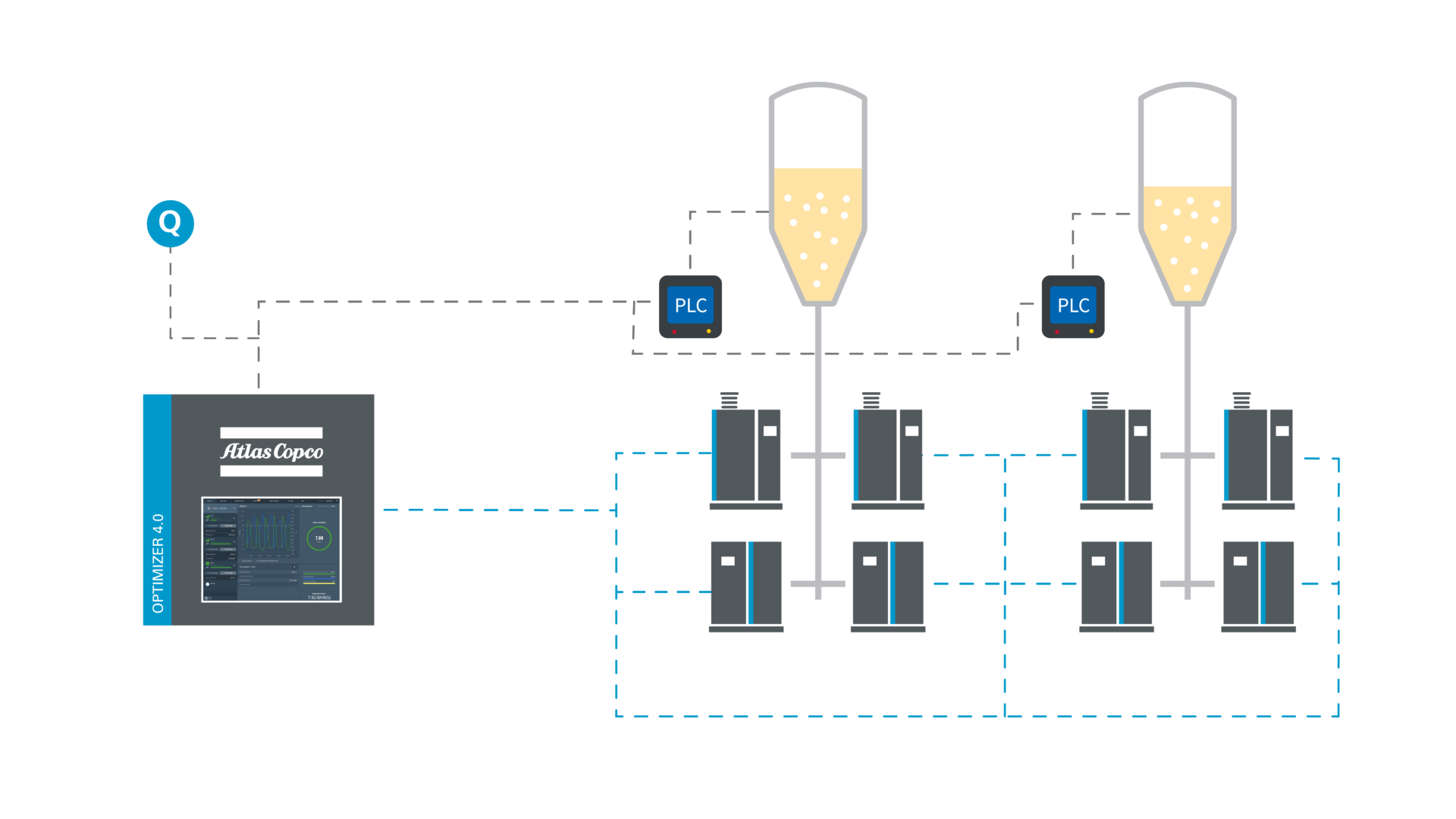

Optimizer 4.0

A properly managed compressed air network will save energy, reduce maintenance, decrease downtime, increase production and improve product quality. Our Optimizer 4.0 monitors and controls the flow of multiple blowers simultaneously; it is one central point of control for the whole compressed air network, ensuring all blowers provide optimum performance for your process. The result is a completely autonomous and energy-efficient network, giving you peace of mind and keeping your costs minimized. Moreover, with our Industry 4.0 applications, you can access the information from your Optimizer wherever you are.

Remote monitoring

Monitor your compressed air installation with SMARTLINK

Knowing the status of your compressed air equipment at all times is the surest way to achieve optimal efficiency and maximum availability.