High reliability

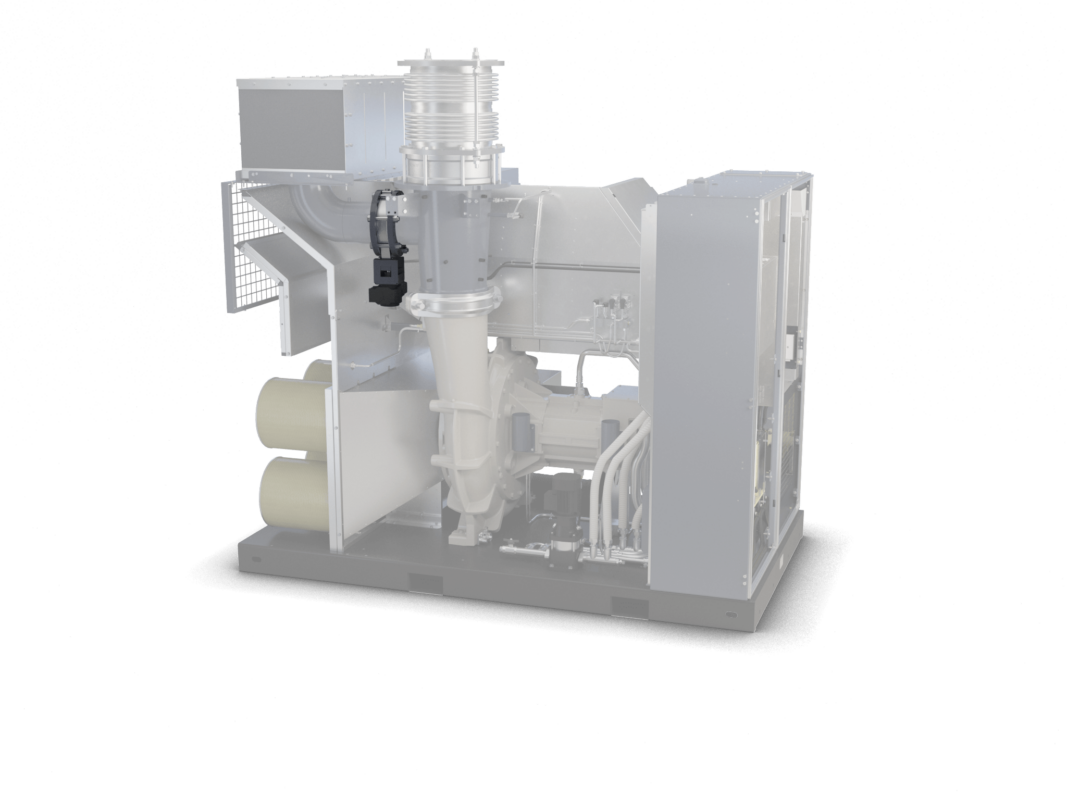

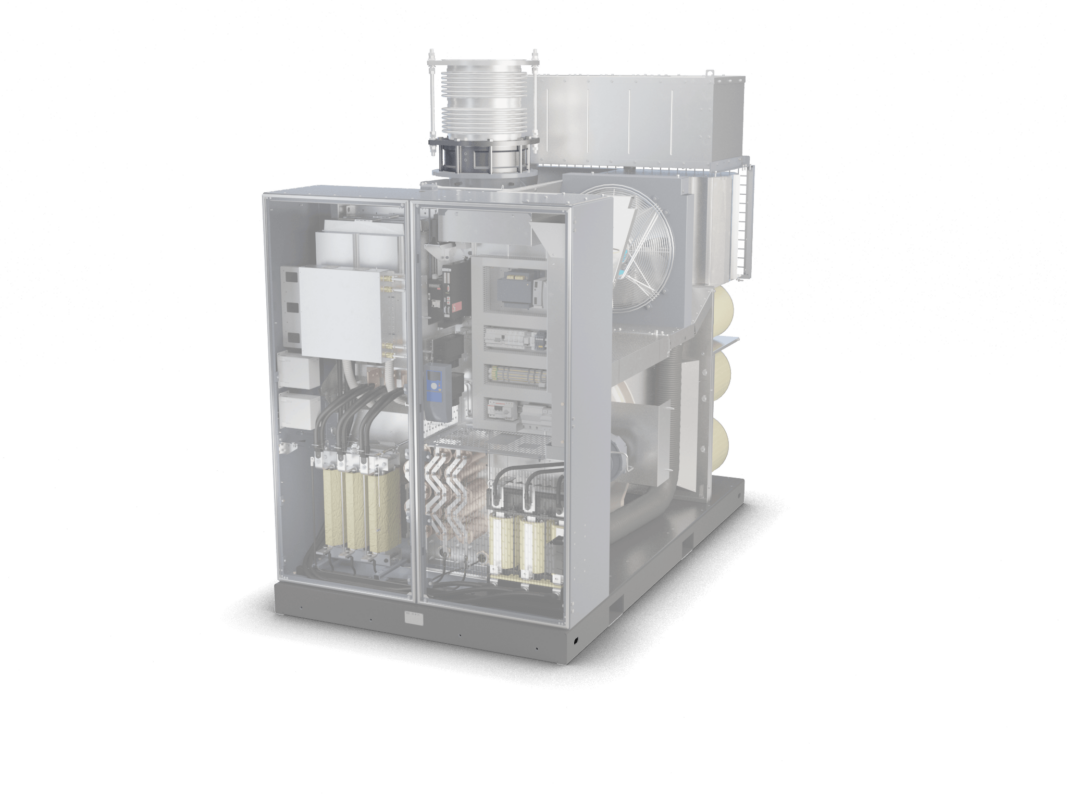

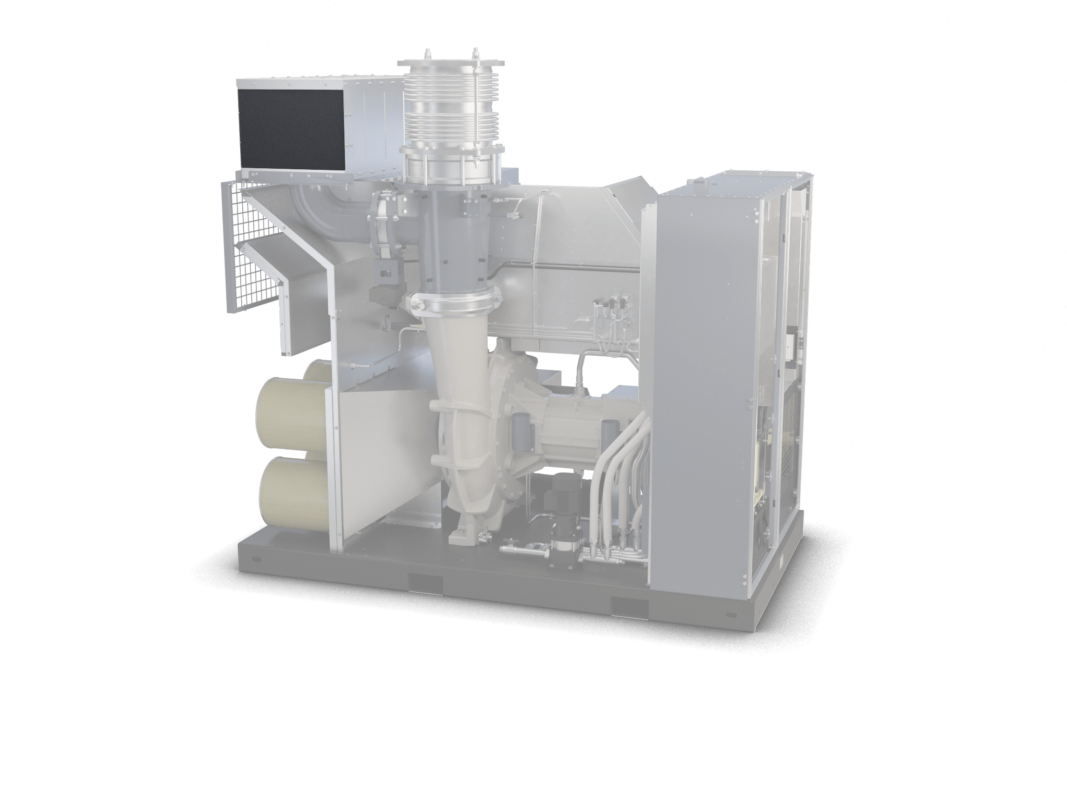

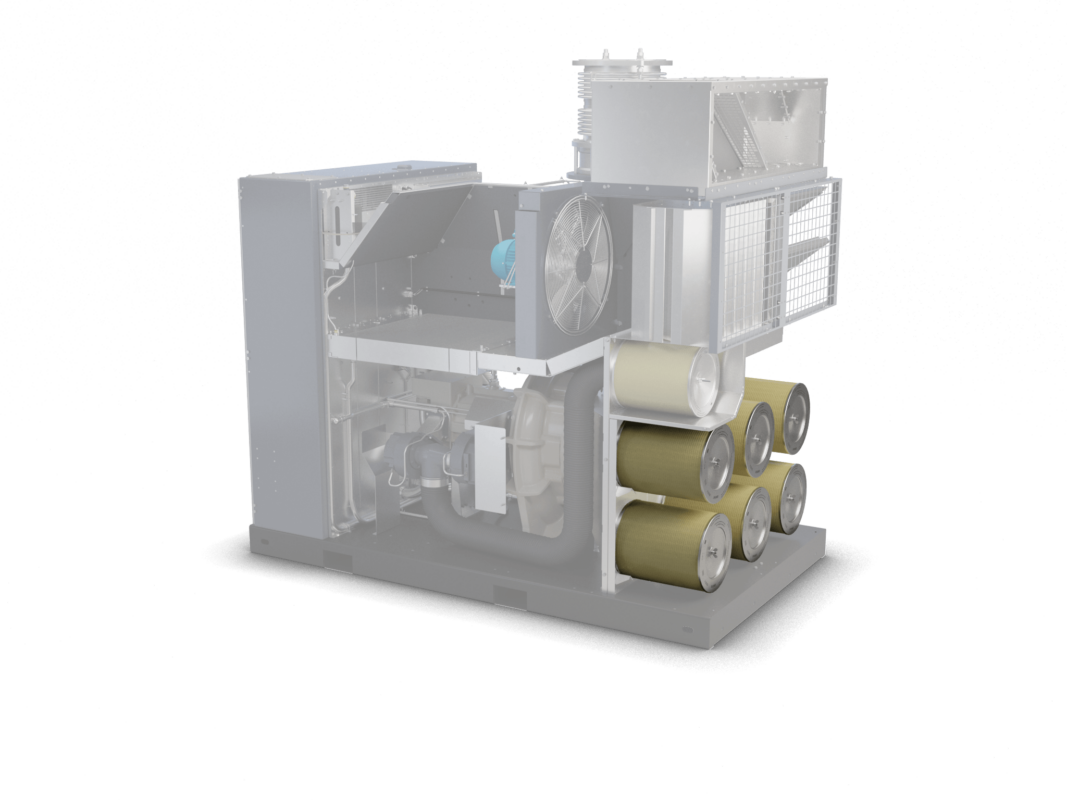

ZB 5-6 VSD⁺

front view

back view

-

1

Protecting electrical cubicle

-

2

Compact and low heat rejection frequency drive

-

3

Magnetic bearing controller

-

4

Minimum internal temperature with heat exchanger cooling fan

-

5

Actuated modulating blow-off valve

-

6

Integrated blow-off silencer

-

7

High-efficient process air filters

-

8

Separated process air inlet

-

9

Magnetic bearing turbo blower

-

10

Check valve

-

Protecting electrical cubicle

The electrical cubicle combines one of the most advanced systems to ensure the machine’s reliability as well as the network in which it is connected to:

• RFI filters reducing harmonic disturbances in the network

• AC chokes against high voltage peaks

• Unit controller

• High-frequency variable speed drive

• DC/DC converter energizing the magnetic bearing controller in case of power failure

• Magnetic bearing controller dynamically adjusting the blower’s shaft position

• LC filters protecting the permanent magnet motor of harmonics

-

Compact and low heat rejection frequency drive

• The high-frequency variable speed drive is the component ensuring the motor’s optimum operation

• Water-cooled, it provides mimum heat rejection and space requirement

-

Magnetic bearing controller

• Compiles information from position sensors to dynamically adjust the shaft’s position

• Full control of the rotor is guaranteed by the magnetic force adjustment

• No external source required nor UPS in case of power failure. Energy is pulled from the variable frequency drive through a DC/DC converter.

-

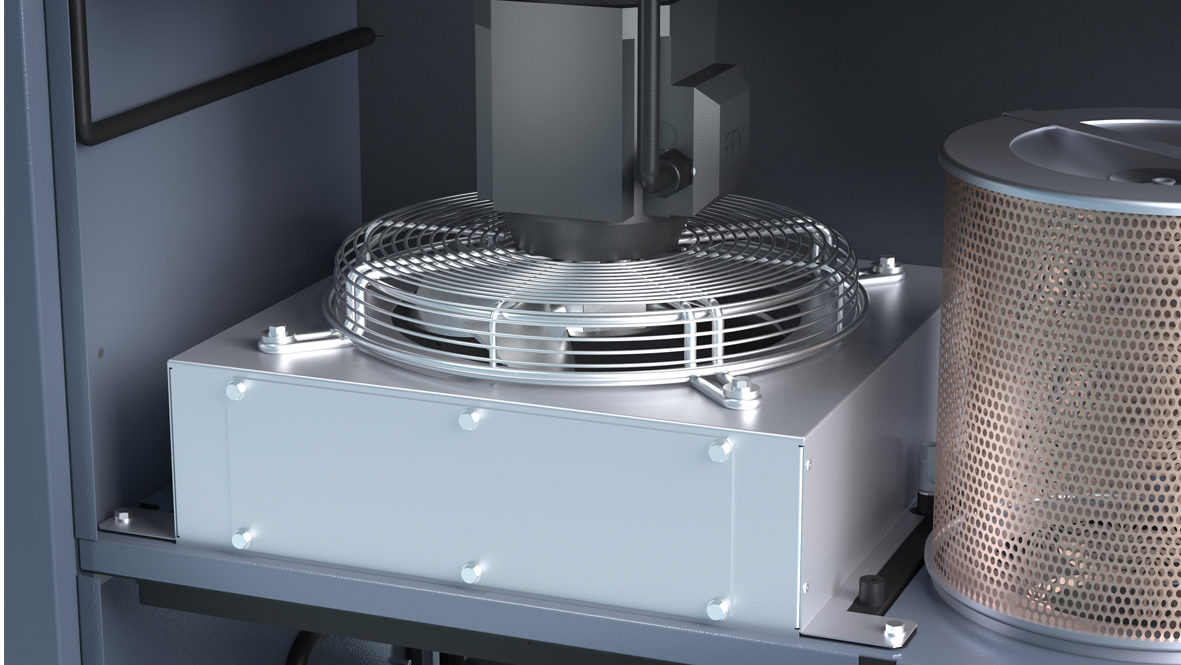

Minimum internal temperature with heat exchanger cooling fan

• Reduces cooling water temperature for the permanent magnet motor and drive

• Cools down mechanical components inside the machine to ensure the lowest opearting temperature and longest lifetime

• Centralized warm cooling air to one single common location on the machine’s roof to ease ducting and heat extraction

-

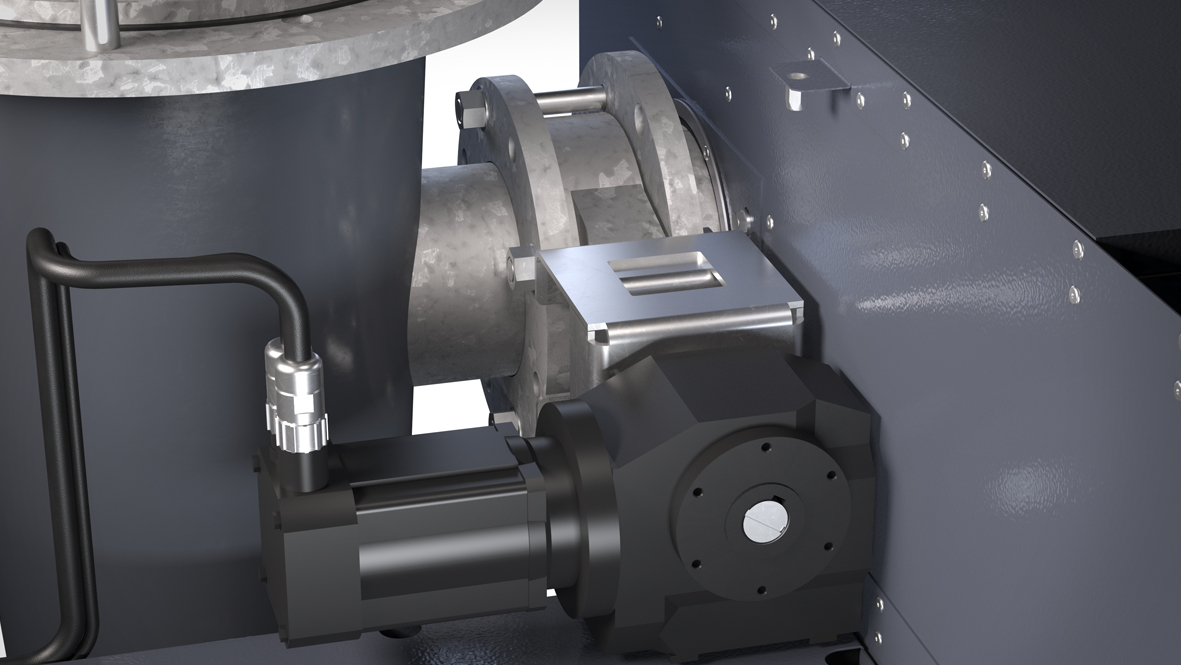

Actuated modulating blow-off valve

• Integrated and factory mounted modulating blow-off valve protecting the blower from overheating

• Assures smooth operation during rapid process changes

• Advanced control algorithm which allows the unit to run in the most efficient way in an extended operating flow range (from 100% to 0% turndown) and unlimited number of starts and stops

-

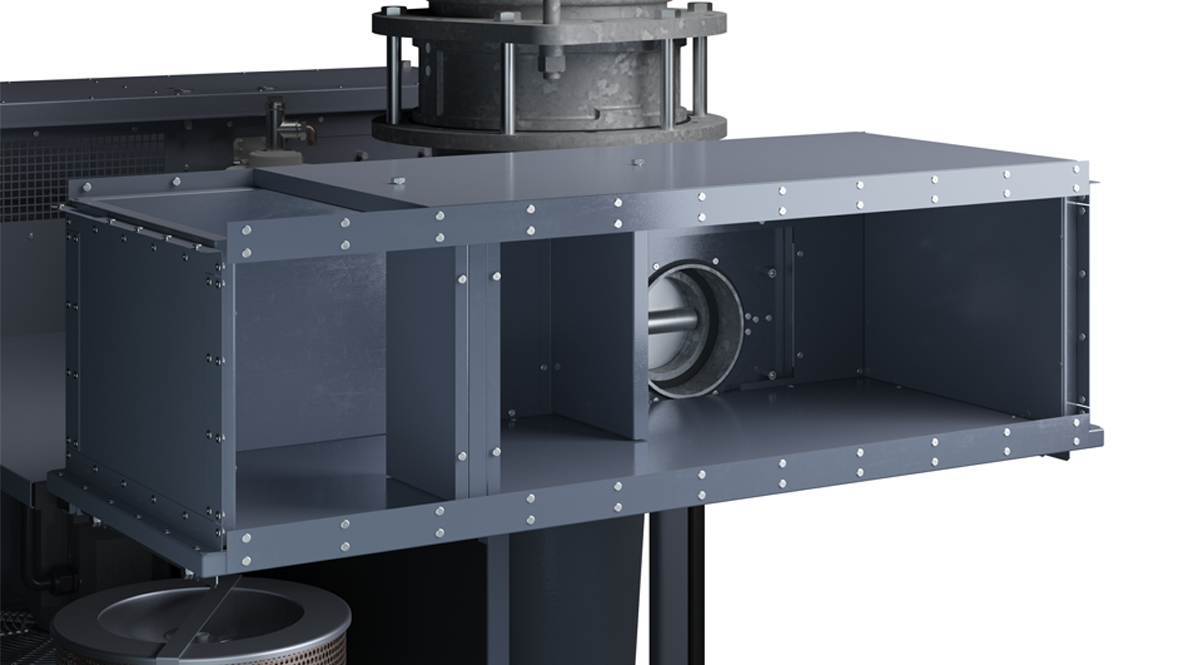

Integrated blow-off silencer

• Integrated and factory mounted blow-off silencer to reduce noise from blow-off operation

• Attenuated noise through built-in internal turns

-

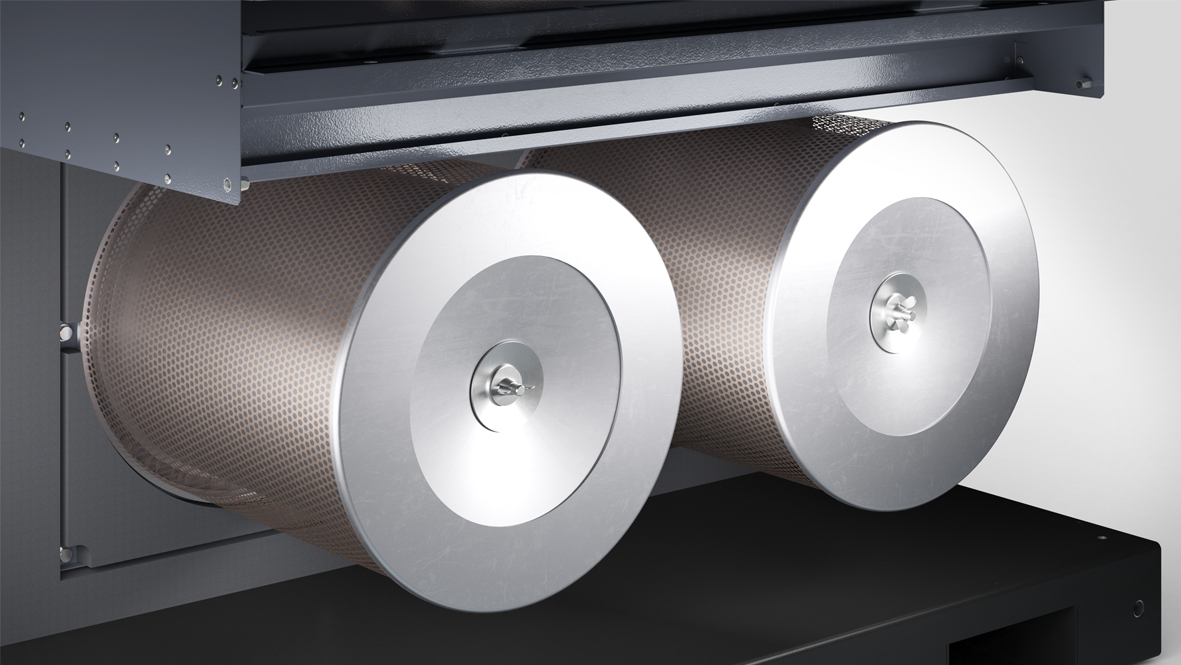

High-efficient process air filters

• Separated process air path to ensure lowest intake temperature and highest mass flow

• Parallel high-efficiency filters

• Easily accessible from the back of the machine and replaceable

-

Separated process air inlet

• Manifold leading air directly from intake point to blower’s impeller to separate it from internal heat

• Maintains the process air temperature to a minimum to increase mass flow delivered by the blower

-

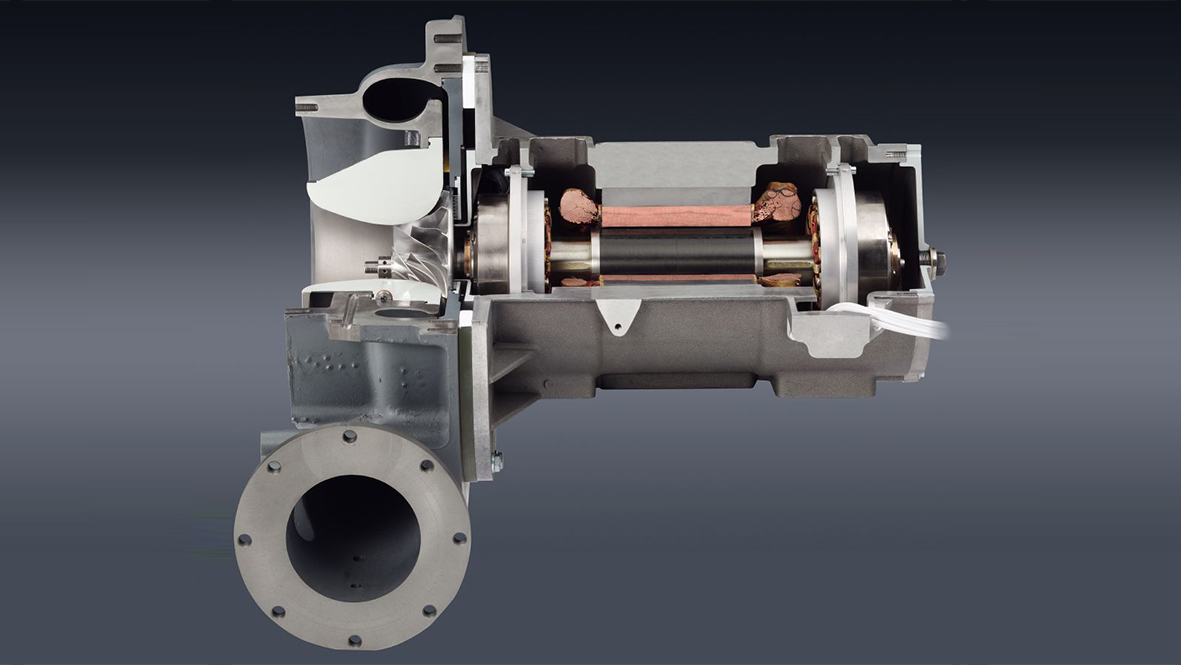

Magnetic bearing turbo blower

• Magnetic bearing technology for highest reliability of all of your operations independently from the downstreams conditions

• Water-cooled permanent magnet motor maintaining the lowest running temperature and longest component lifetime

-

Check valve

• High-efficiency check valve to protect blower when not operating

• Lowest pressure drops to minimize the performance’s impact

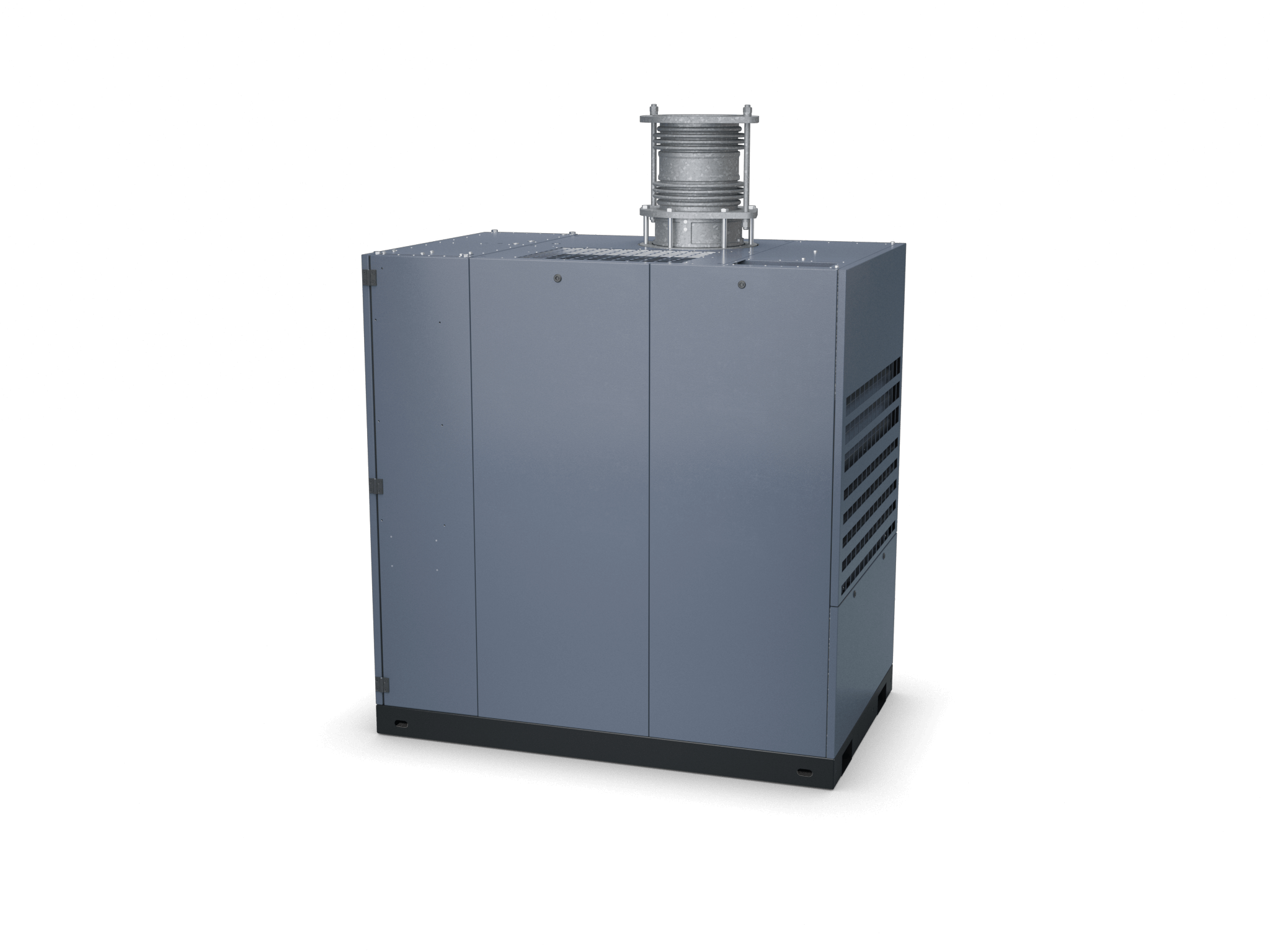

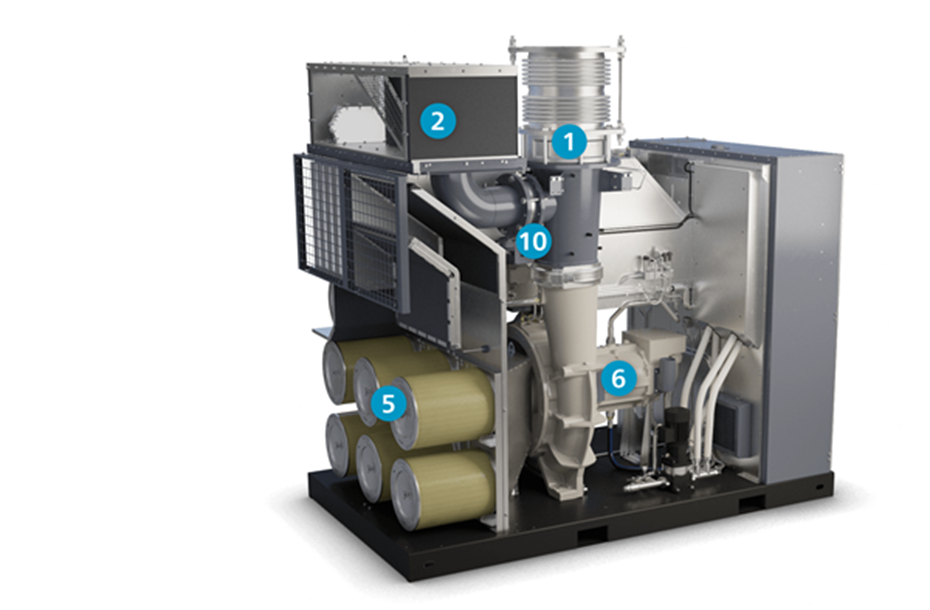

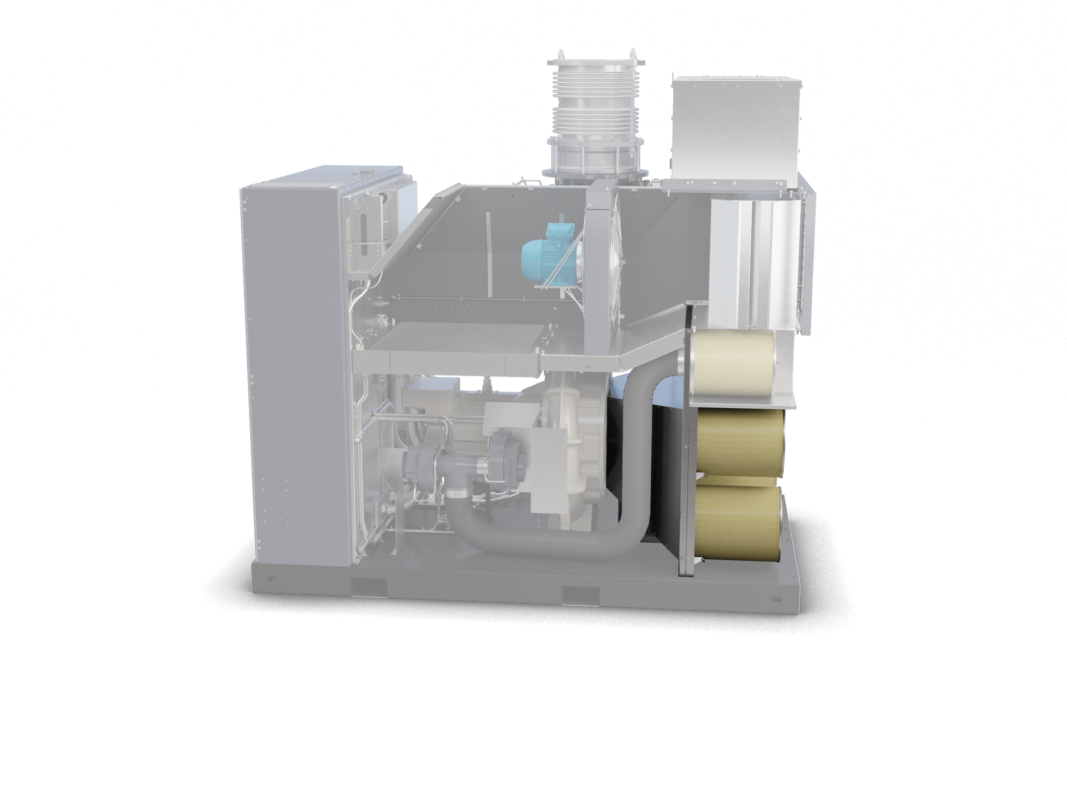

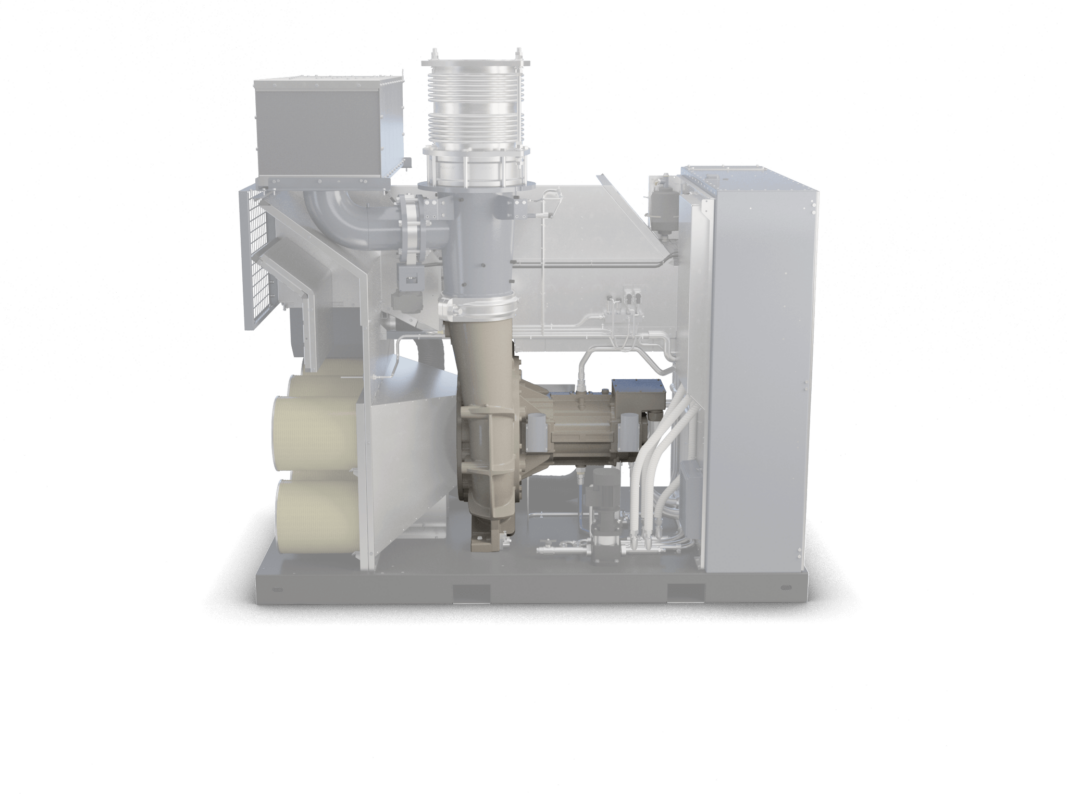

ZB 7 VSD⁺

front view

back view

-

1

Check valve

-

2

Integrated blow-off silencer

-

3

Minimum internal temperature with heat exchanger cooling fan

-

4

Separated process air inlet

-

5

High-efficient process air filters

-

6

Magnetic bearing turbo blower

-

7

Compact and low heat rejection frequency drive

-

8

Magnetic bearing controller

-

9

Protecting electrical cubicle

-

10

Actuated modulating blow-off valve

-

Check valve

• High-efficiency check valve to protect blower when not operating

• Lowest pressure drops to minimize the performance’s impact

-

Integrated blow-off silencer

• Integrated and factory mounted blow-off silencer to reduce noise from blow-off operation

• Attenuated noise through built-in internal turns

-

Minimum internal temperature with heat exchanger cooling fan

• Reduces cooling water temperature for the permanent magnet motor and drive

• Cools down mechanical components inside the machine to ensure the lowest opearting temperature and longest lifetime

• Centralized warm cooling air to one single common location on the machine’s roof to ease ducting and heat extraction

-

Separated process air inlet

• Manifold leading air directly from intake point to blower’s impeller to separate it from internal heat

• Maintains the process air temperature to a minimum to increase mass flow delivered by the blower

-

High-efficient process air filters

• Separated process air path to ensure lowest intake temperature and highest mass flow

• Parallel high-efficiency filters

• Easily accessible from the back of the machine and replaceable

-

Magnetic bearing turbo blower

• Magnetic bearing technology for highest reliability of all of your operations independently from the down streams conditions

• Water-cooled permanent magnet motor maintaining the lowest running temperature and longest component lifetime

-

Compact and low heat rejection frequency drive

• The high-frequency variable speed drive is the component ensuring the motor’s optimum operation

• Water-cooled, it provides minimum heat rejection and space requirement

-

Magnetic bearing controller

• Compiles information from position sensors to dynamically adjust the shaft’s position

• Full control of the rotor is guaranteed by the magnetic force adjustment

• No external source required nor UPS in case of power failure. Energy is pulled from the variable frequency drive through a DC/DC converter.

-

Protecting electrical cubicle

The electrical cubicle combines one of the most advanced systems to ensure the machine’s reliability as well as the network in which it is connected to:

• RFI filters reducing harmonic disturbances in the network

• AC chokes against high voltage peaks

• Unit controller

• High-frequency variable speed drive

• DC/DC converter energizing the magnetic bearing controller in case of power failure

• Magnetic bearing controller dynamically adjusting the blower’s shaft position

• LC filters protecting the permanent magnet motor of harmonics

-

Actuated modulating blow-off valve

• Integrated and factory mounted modulating blow-off valve protecting the blower from overheating

• Assures smooth operation during rapid process changes

• Advanced control algorithm which allows the unit to run in the most efficient way in an extended operating flow range (from 100% to 0% turndown) and unlimited number of starts and stops