The right product for a wide range of low pressure or vacuum applications

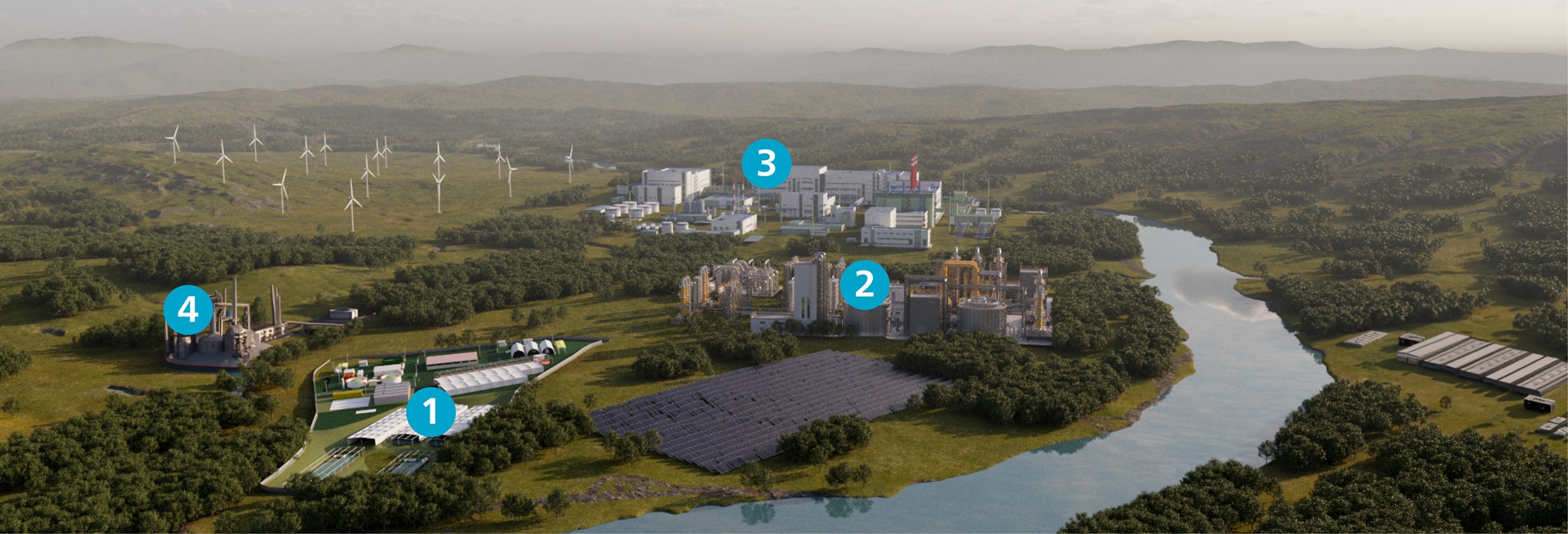

The positive displacement principle with fix characteristics makes the product suitable for tons of applications. Whether it is pneumatic transport of granulates, fluidization of silos, aeration process in waste water treatment plants or process air in chemical plants; the ZL blowers can work in overpressure or vacuum mode, and bring reliable, uninterrupted operation around the clock.

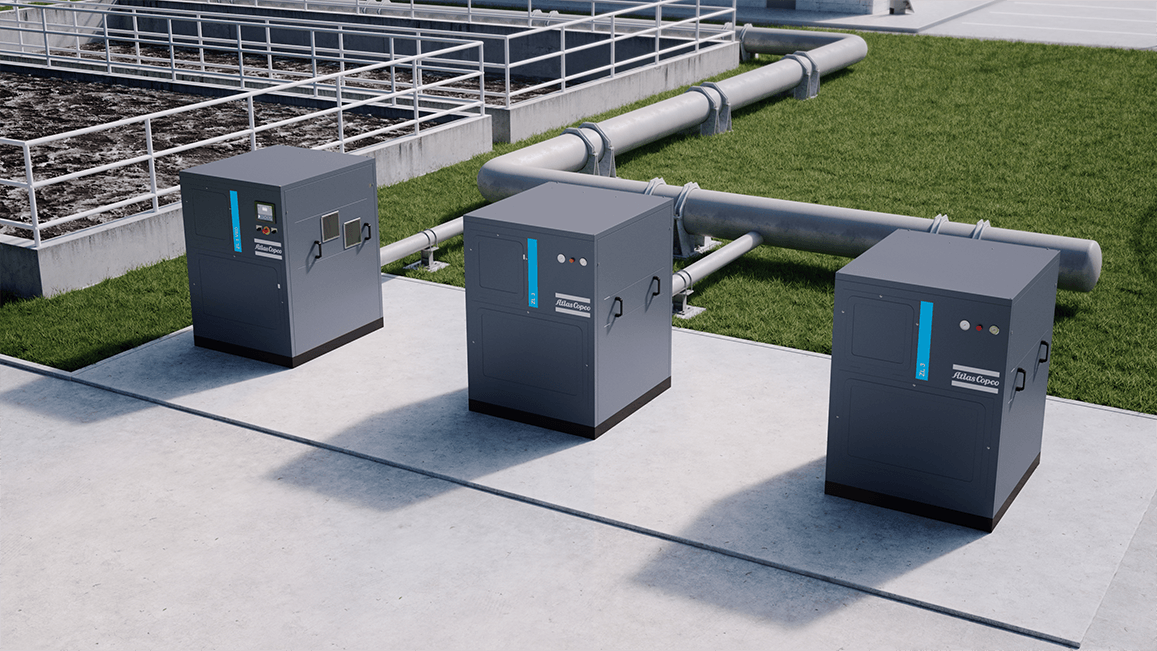

1. Wastewater treatment plants

Source of reliable compressed air where you need it

The reliable design of ZL blowers makes it possible to install them where you need them, i.e. close to the technology, even outdoors. No need for a dedicated blower room, the ZL blower drives the capital costs for the whole WWTP down. Easy maintenance in regular intervals gives you ease-of-mind for the total plants’ lifetime.

2. Cement industry

Reliable air supply in dusty environment

Whether you need a blower for pneumatic transport of solid fuel, for main combustion air or for lance cooling air, the ZL unit is strong enough to cope with these demands. Though the environment in cement plant is often harsh and dusty, the ZL lobe blower’s proven element with sturdy frame will provide trouble-free operation.

3. Food and beverage

Quality of product is key

In the Food and Beverage industry, it is crucial to keep the quality of the product high ensuring no contamination from foreign particles or unfit materials.

4. Power

Smooth and reliable operation 24/7

Applications in power plants such as desulphurization or combustion process require intermittent operation of the blower with variable air demand. A high number of starts can be very demanding for the bearings in element and motor and for the check valve. The start-up function of the (standard-built-in) PVO valve ensures a smooth pressure build-up and thus prolongs the lifetime of those components. The integrated VSD control of the ZL blower then provides always the right volume of air.

Wastewater treatment

Municipal wastewater

Pulp and paper

Pharma

Food and beverage

Oil and gas

Aquaculture

Pneumatic conveying

Food and beverage

Cement and lime

Power

Aquaculture

Textile

Gas handling

Biogas

Food and beverage

Water treatment

Distillation

Drink water

Floating cells

Mining

Vacuum conveying

Plastics

Furniture industry