Energy savings

Design & control algorithms for optimal efficiency.

Variable Speed Drive

Over 80% of a blower’s lifecycle cost is taken up by the energy it consumes. Moreover, the generation of compressed air can account for more than 40% of a plant’s total electricity bill. To cut your energy costs, Atlas Copco pioneered Variable Speed Drive

(VSD) technology in the compressed air industry. VSD leads to major energy savings, while protecting the environment for future generations. Thanks to continual investments in this technology, Atlas Copco offers the widest range of integrated VSD blowers on the market.

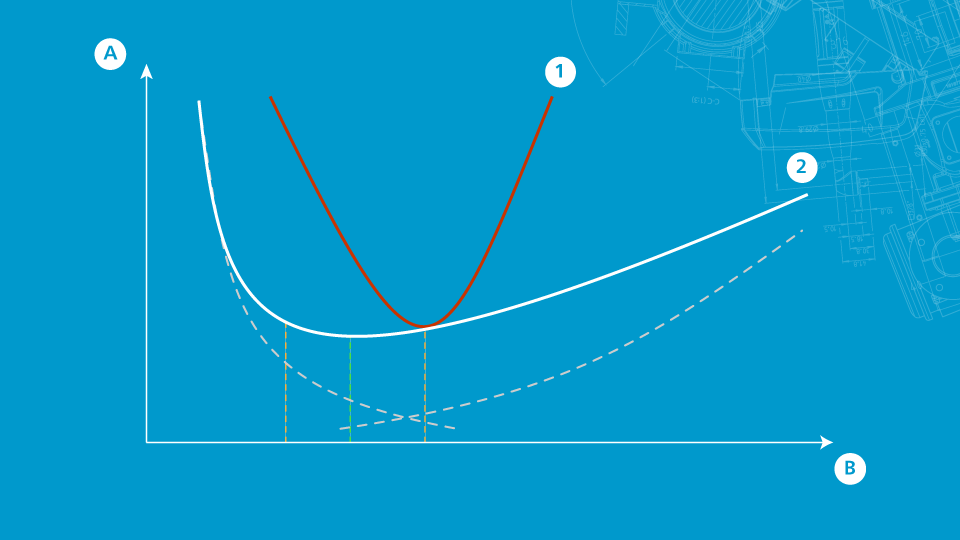

Legend

A = Losses

B = Speed

1 = Total losses traditional element

VSD Savings

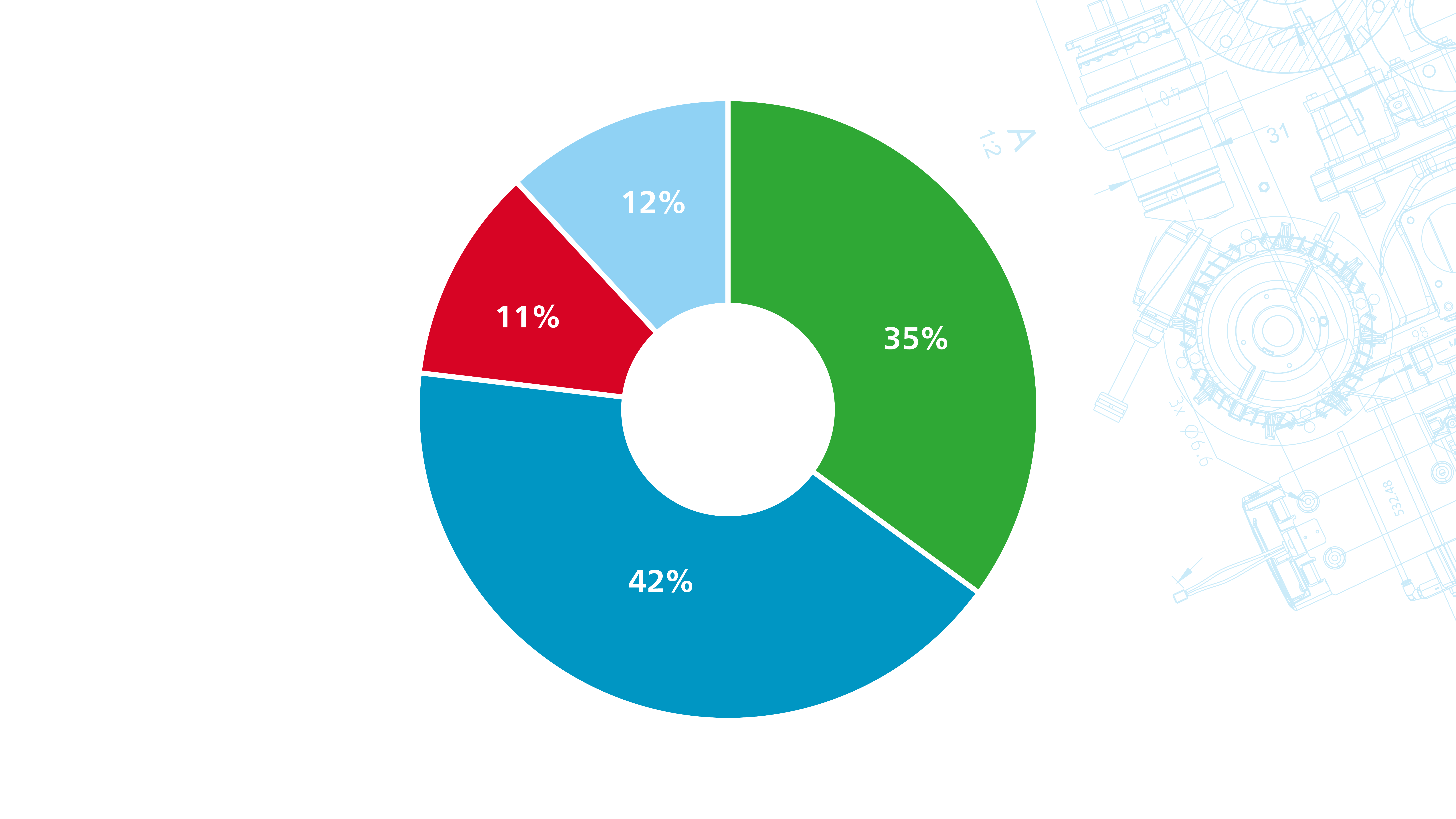

Atlas Copco’s VSD technology closely follows the air demand by automatically adjusting the motor speed. This results in large energy savings of up to 35%. The Life Cycle Cost of a blower can be cut by an average of 22%. In addition, lowered system

pressure with VSD minimizes energy use across your production dramatically.

Legend

42% = Energy

35% = Energy savings with VSD

12% = Investment

11% = Maintenance

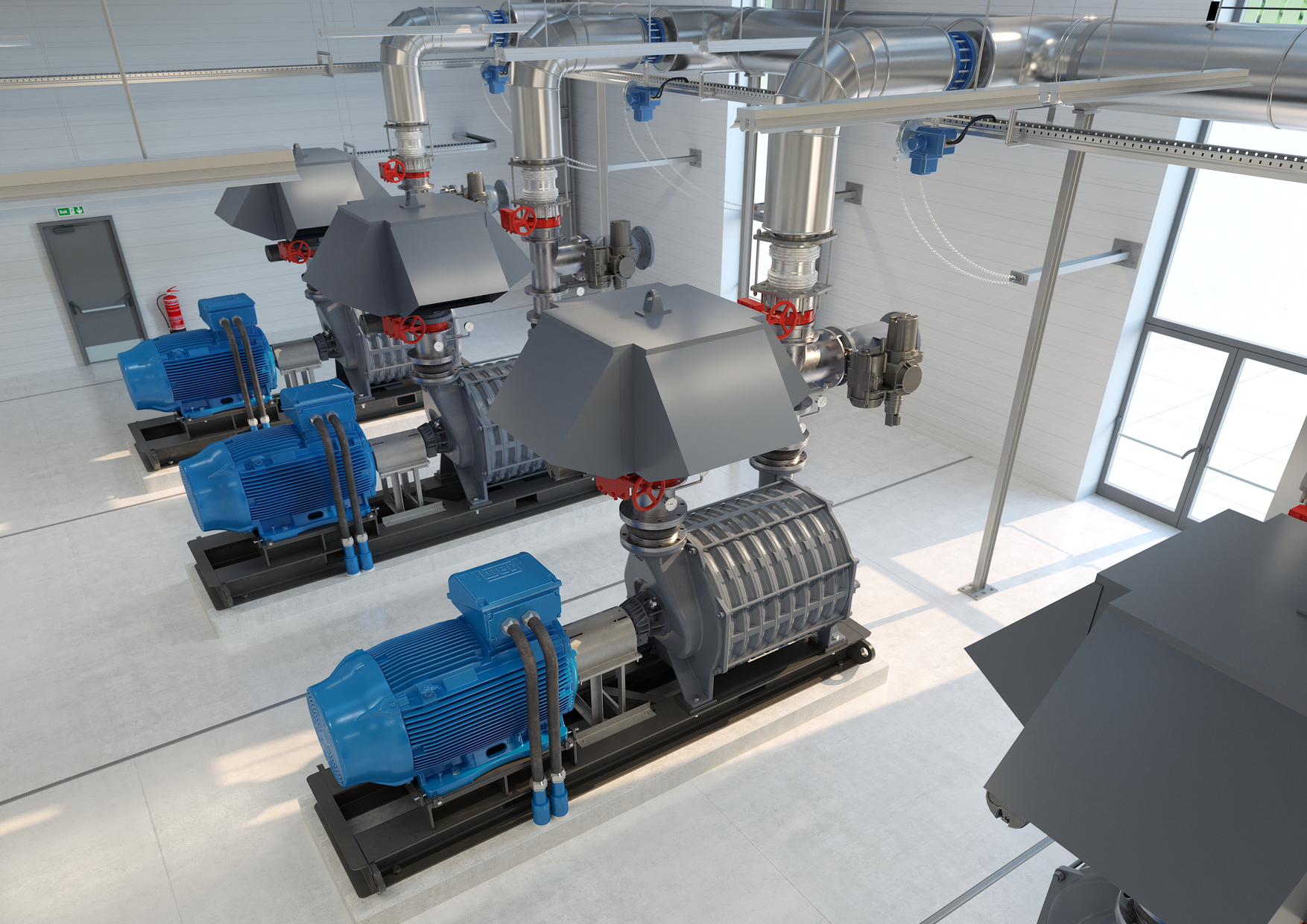

Components designed for maximum efficiency

The strength of the multistage blower design is the ability to select both the number of compression stages and the impeller design of each stage to match the blower performance to your process requirements with maximum efficiency.

Each blower package is provided with a premium efficient induction motor to drive the blower element. These motors can be suitable for fixed speed or variable speed operation and provided for a variety of voltages.