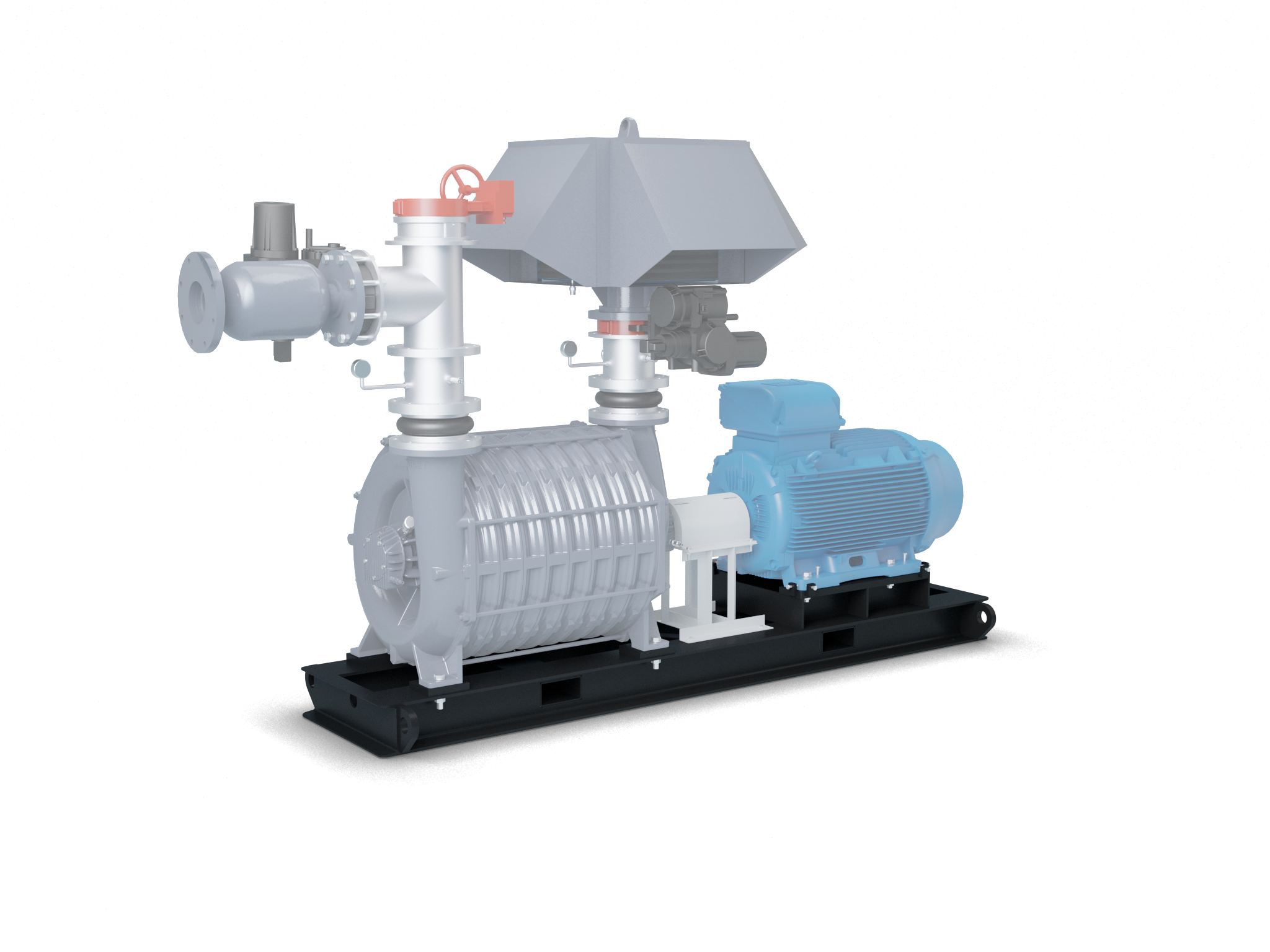

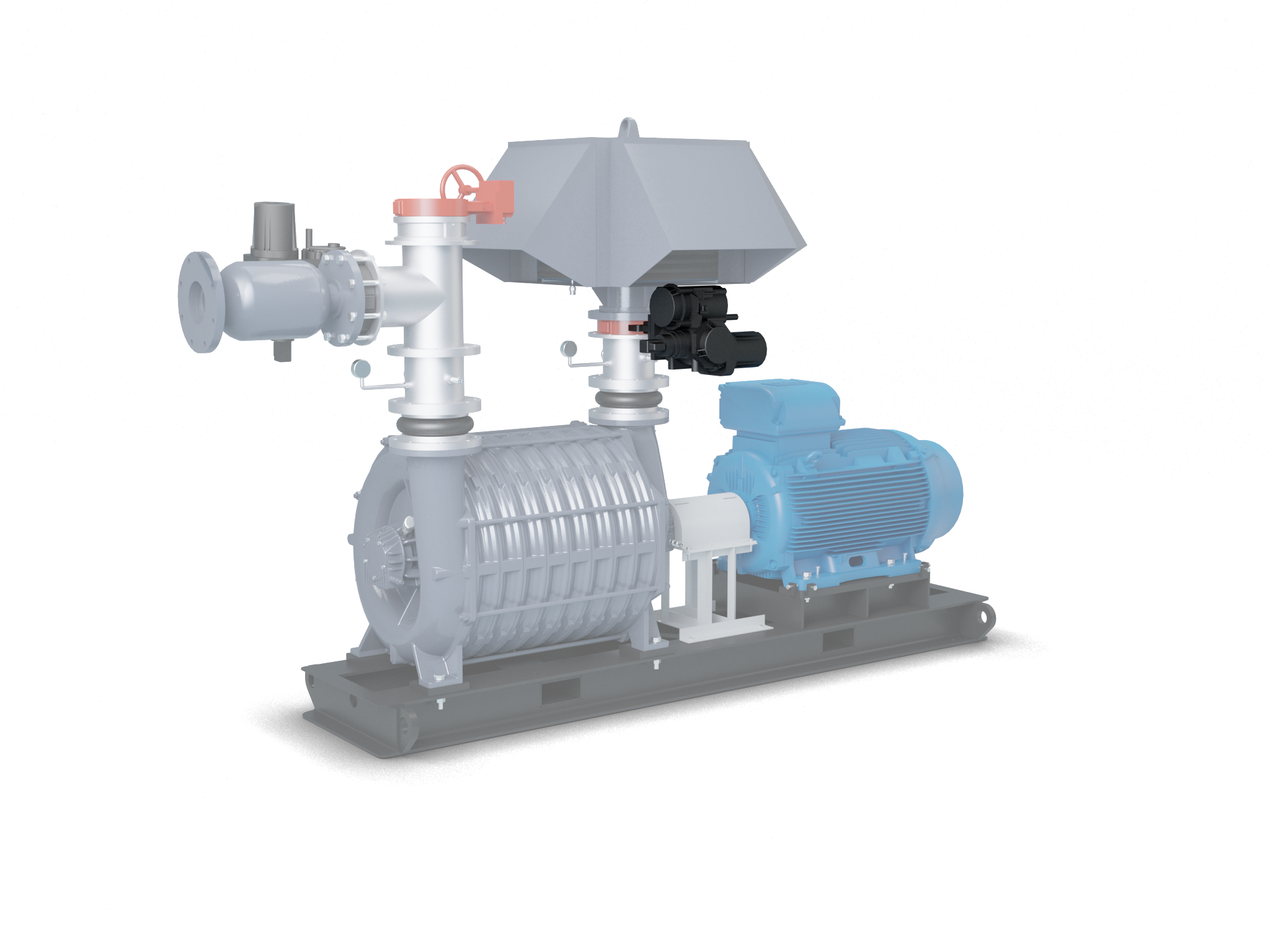

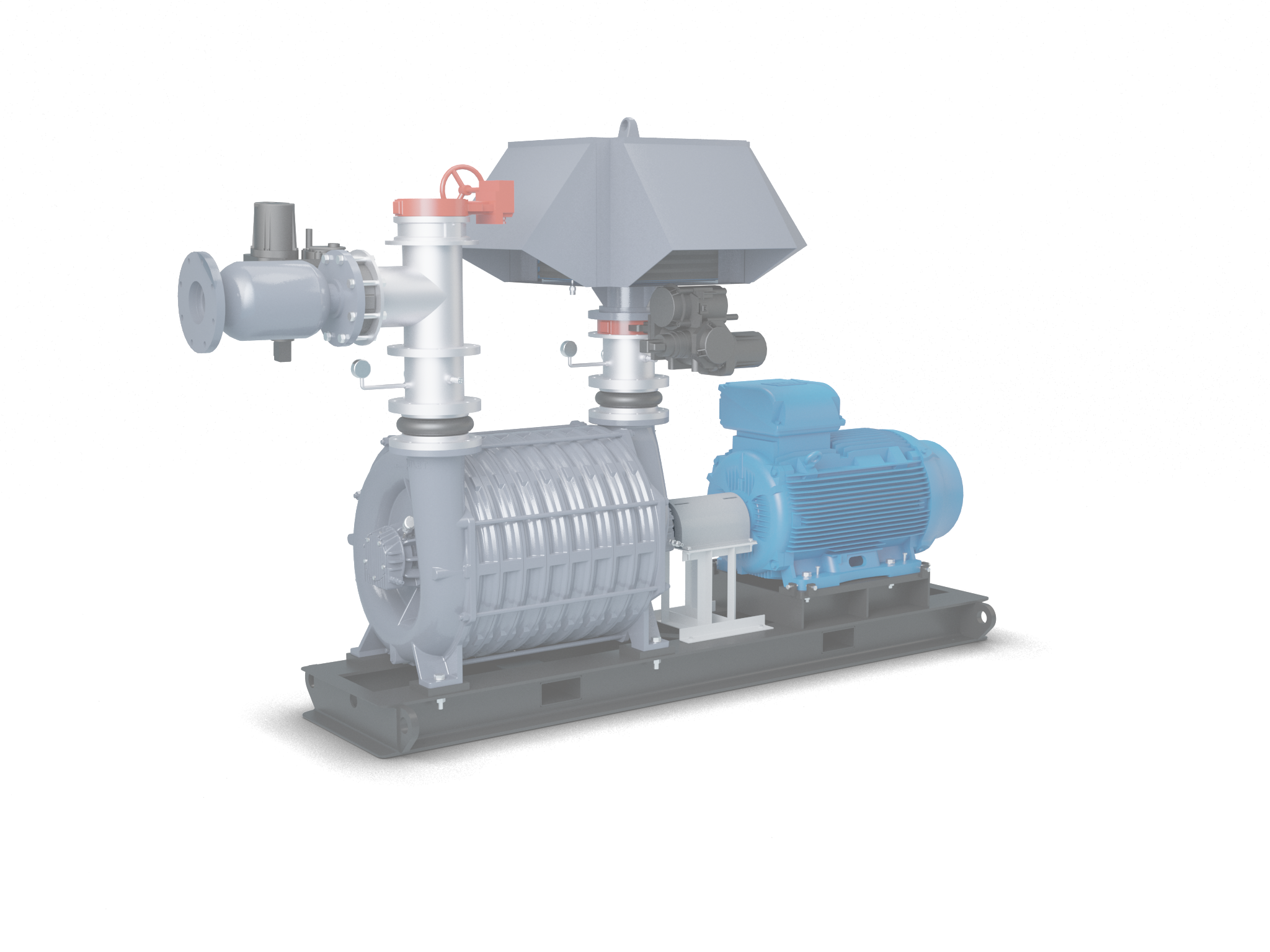

ZM 4-10

-

1

Inlet filter/silencer

-

2

Flow regulation

-

3

Instrumentation

-

4

Expansion joints

-

5

Blow-off assembly

-

6

Check valve & isolation valve

-

7

Induction motor

-

8

Coupling & coupling guard

-

9

Structural skid for easy installment

-

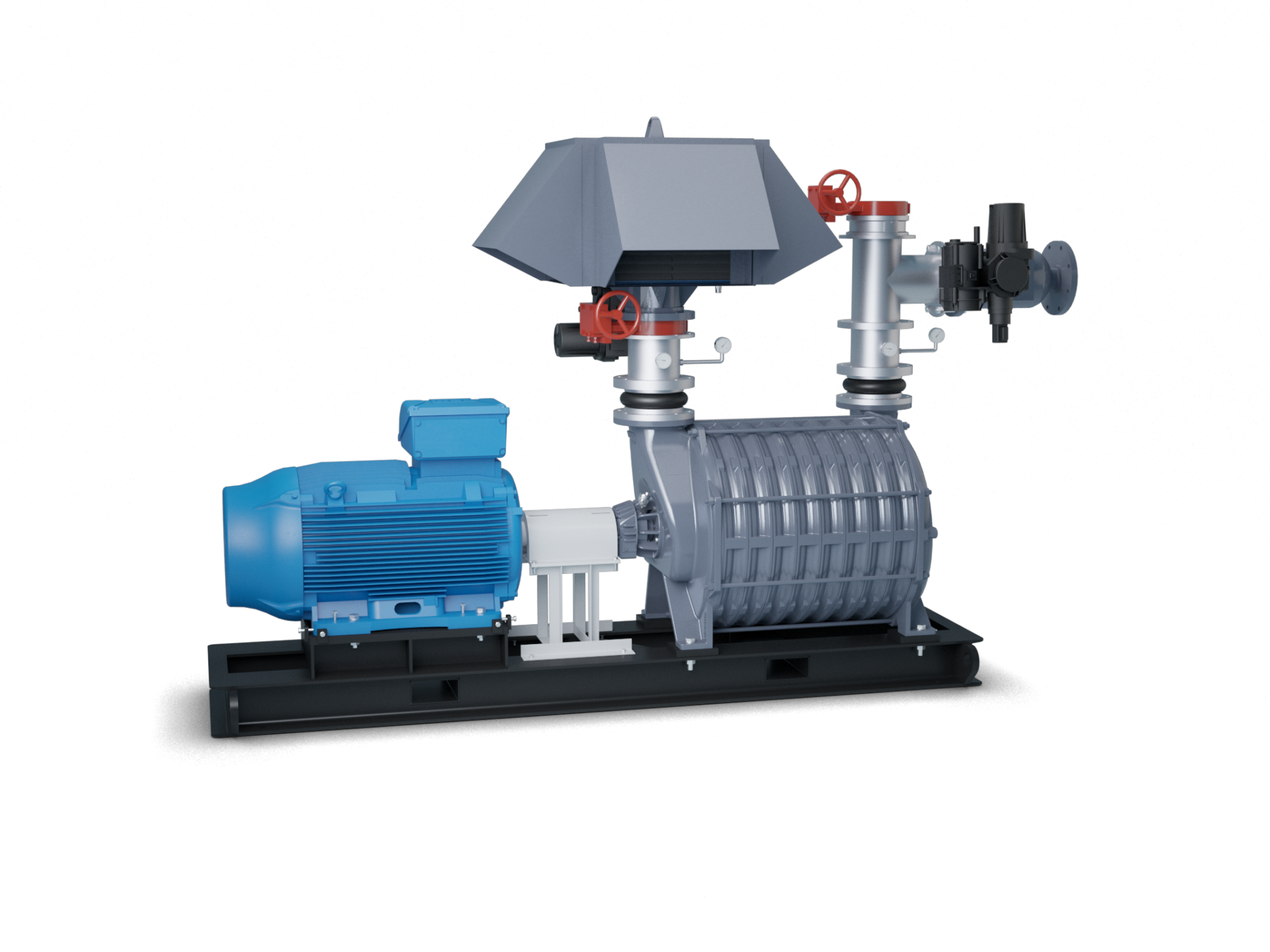

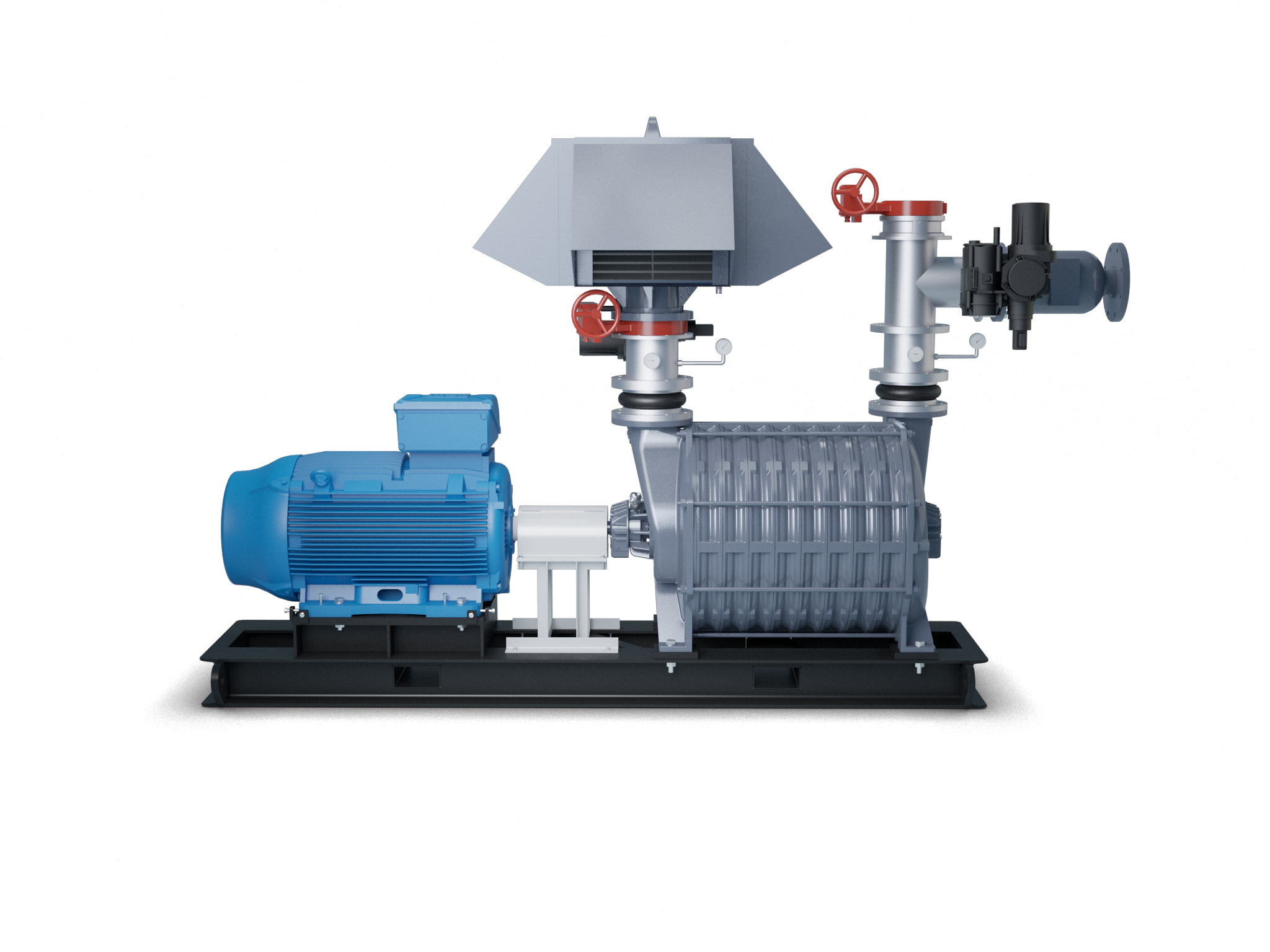

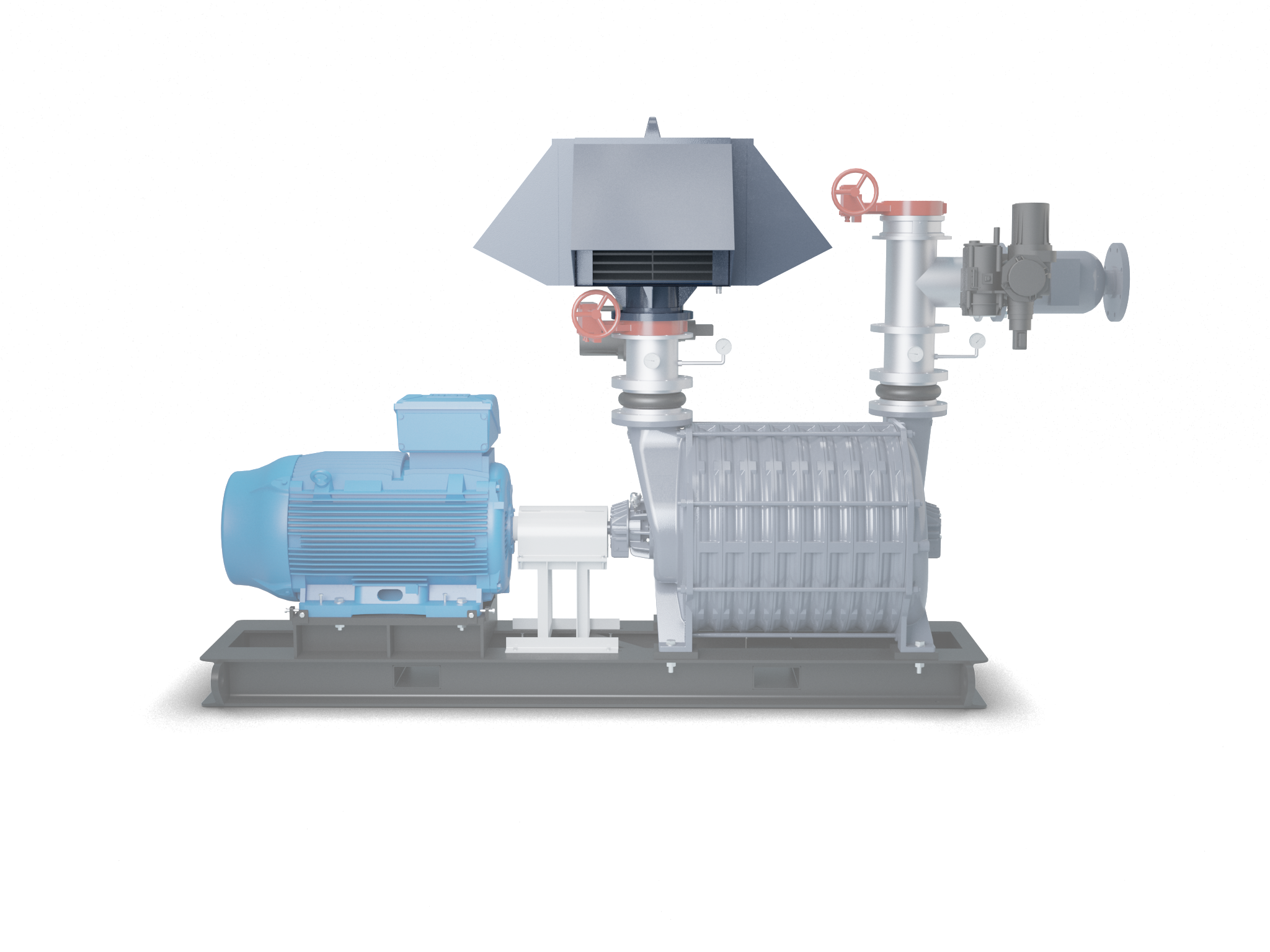

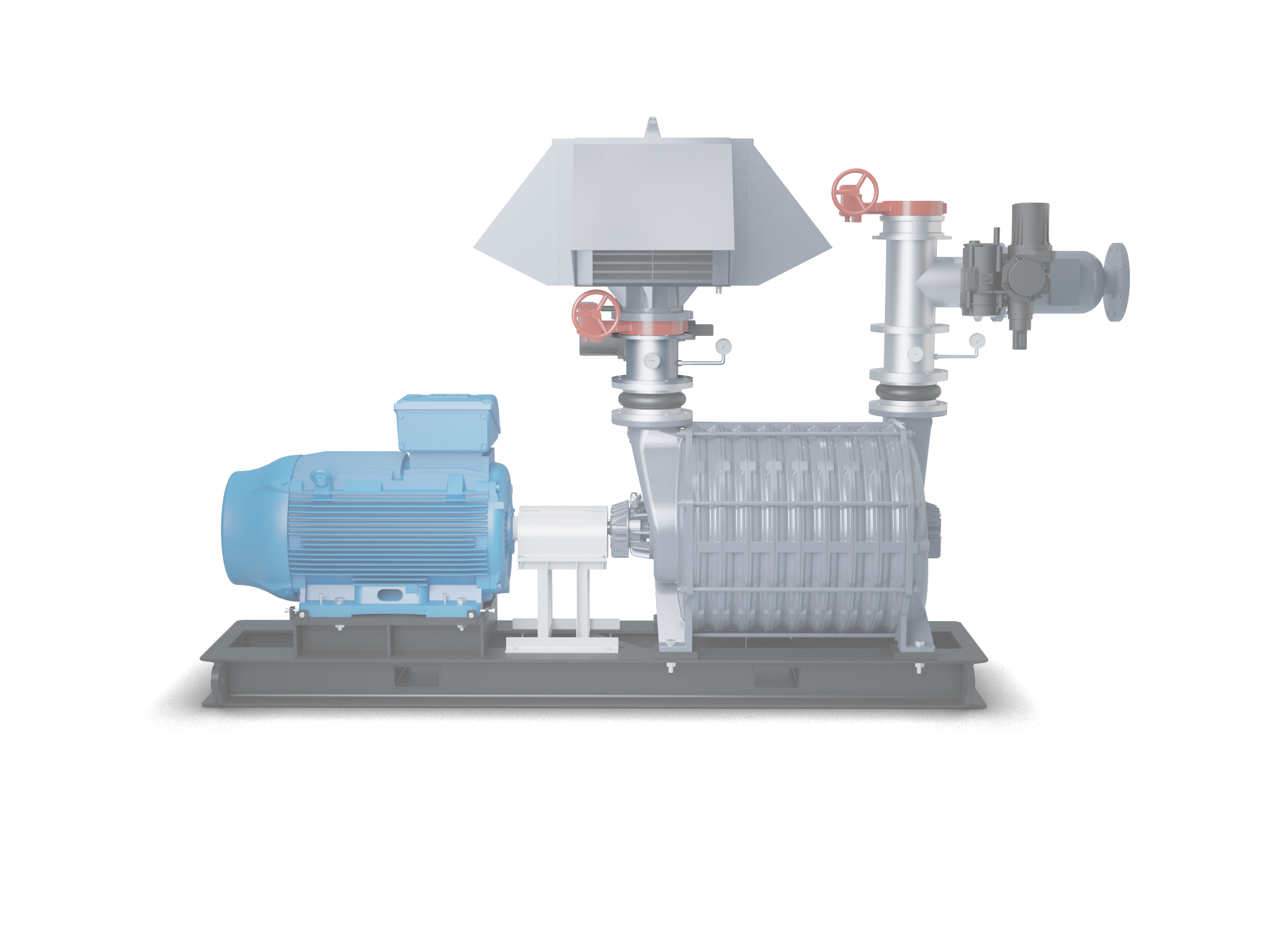

Inlet filter/silencer

The inlet filter/silencer is a combined function component that removes 98% of particles greater than 10 microns in size out of the inlet air while also reducing the sound emissions from the inlet airflow. Custom filtration solutions are also available for finer particle filtration or special areas, such as those prone to sandstorms.

-

Flow regulation

The flow regulation of the blower can be achieved in two ways; with a throttling valve and actuator to adjust the butterfly valve position (as shown in the model) or with a variable speed drive (VSD) to adjust the motor speed. The VSD option can offer significant energy savings for those processes that have highly variable flows.

-

Instrumentation

As a standard we offer the blower packages with sensors/transmitters to work with our control panel options, but we can also supply simple gauges or no instruments at all.

-

Expansion joints

Expansions joints are supplied to allow for thermal expansion of connected pipework without causing excessive forces on the blower flanges, as well as the decouple any vibration from the piping. Stainless steel variants are also available for especially harsh applications.

-

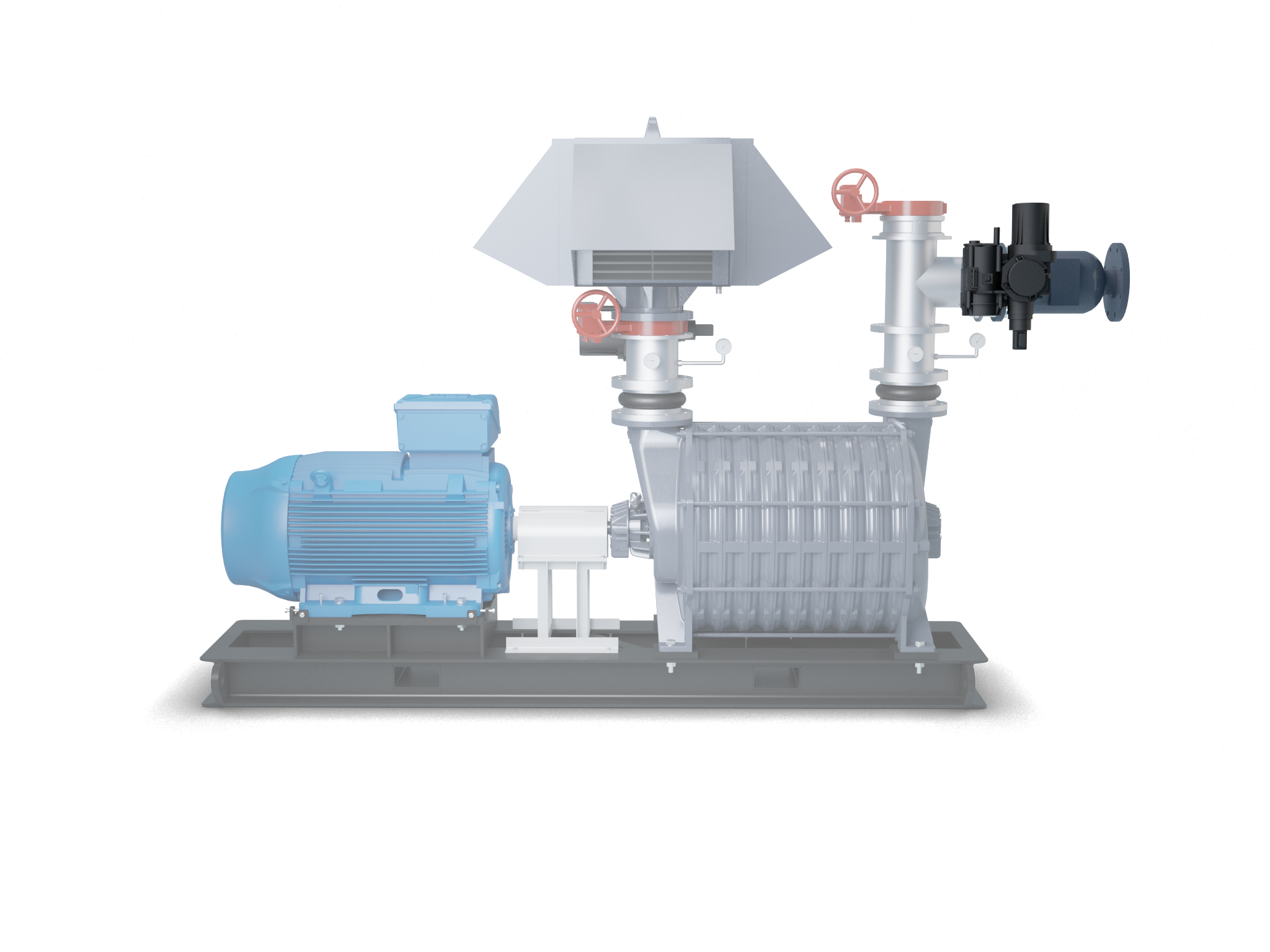

Blow-off assembly

The blow-off assembly consists of the piping tee, modulating electric actuator, and silencer. This optional assembly provides additional protection against surge during startup and operation. It can also be used to provide flows to a process below the surge limit of the blower.

-

Check valve & isolation valve

The check valve prevents the pressure of the downstream process from causing a backwards flow through machines that are not in operation, which can cause severe damage. In addition, an isolation valve can be used to completely isolate the blower from the process for maintenance.

-

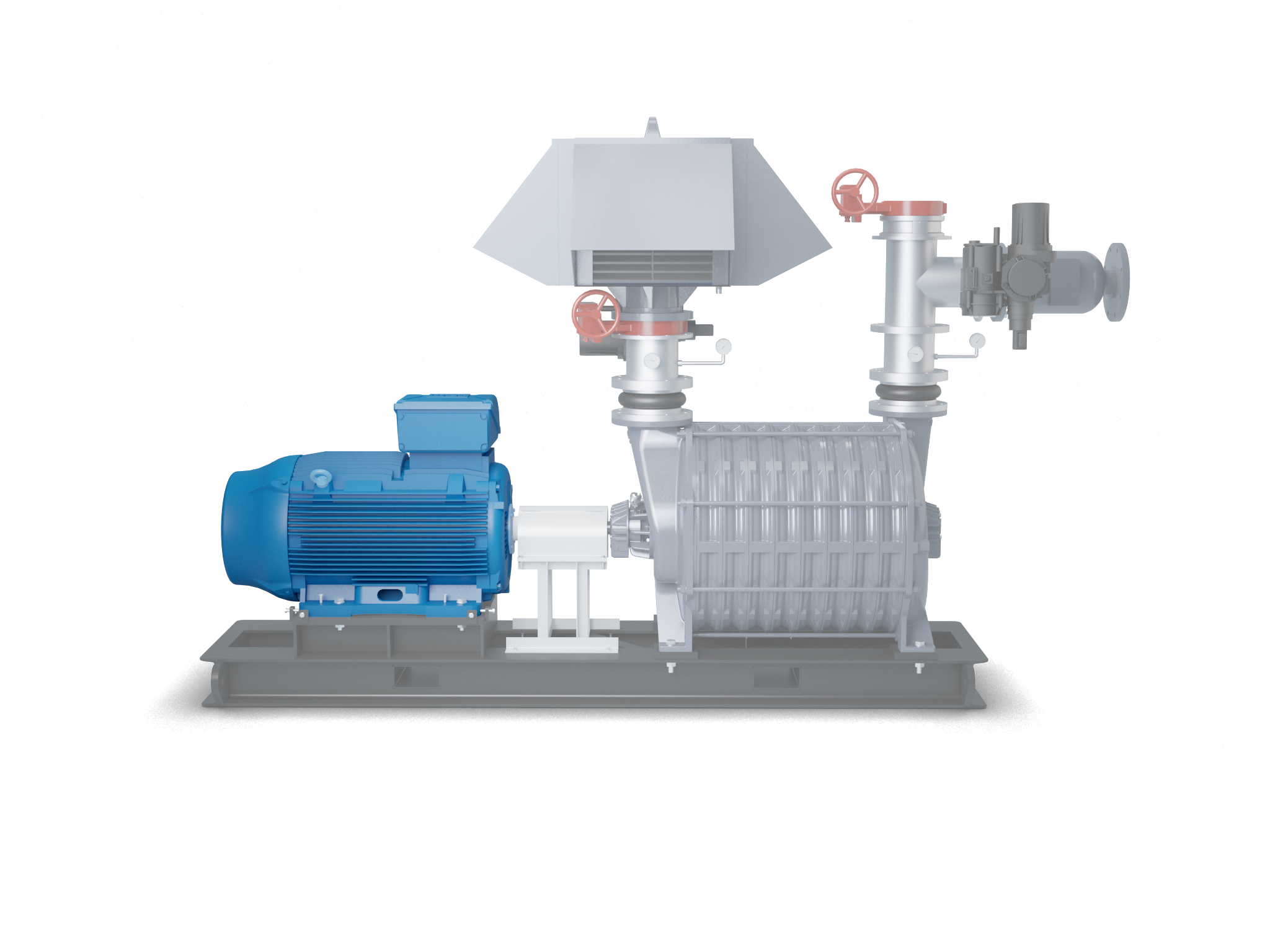

Induction motor

Each blower package is provided with a premium efficient induction motor to drive the blower element. These motors can be suitable for fixed speed or variable speed operation and provided for a variety of voltages. In addition to the motor, we can also supply the starter (fixed speed operation) or variable speed drive (VSD) as well.

-

Coupling & coupling guard

The motor is directly coupled to the blower element with either an elastomeric or flexible disc type coupling depending on the motor size. The rotating shafts are protected by a guard that meets OSHA requirements for machine safety.

-

Structural skid for easy installment

The blower assembly is mounted to a steel skid with the ability to be moved with forklift slots or lifting eyes.