VSD: driving down energy costs

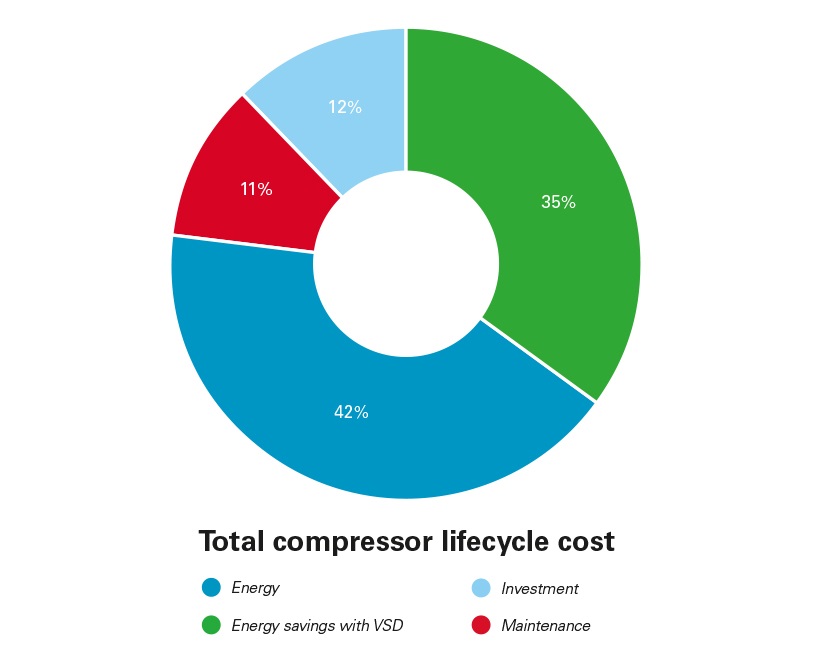

Over 80% of a compressor’s lifecycle cost is taken up by the energy it consumes. Moreover, the generation of compressed air can account for more than 40% of a plant’s total electricity bill. To cut your energy costs, Atlas Copco pioneered Variable Speed Drive (VSD) technology in the compressed air industry.

Energy savings up to 35%

Atlas Copco’s Variable Speed Drive technology leads to major energy savings, while protecting the environment for future generations. Thanks to continual investments in this technology, Atlas Copco offers the widest range of integrated VSD compressors on the market.

Atlas Copco’s VSD technology closely follows the air demand by automatically adjusting the motor speed. This results in large energy savings of up to 35%. The Life Cycle Cost of a compressor can be cut by an average of 22%. In addition, lowered system pressure with VSD minimizes energy use across your production dramatically.

What is unique about the integrated Atlas Copco VSD?

The Elektronikon® controls both the compressor and the integrated converter, ensuring maximum machine safety within parameters.

Flexible pressure selection with VSD reduces electricity costs.

Specific converter and motor design (with protected bearings) for the highest efficiency across the speed range.

Electric motor specifically designed for low operating speeds with clear attention to motor cooling and compressor cooling requirements.

Mechanical enhancements ensure that all components operate below critical vibration levels throughout the entire compressor speed range.

A highly efficient frequency converter in a cubicle ensures stable operation in high ambient temperatures up to 50°C/122°F (standard up to 40°C/104°F).

Net pressure band is maintained within 0.10 bar, 1.5 psi.