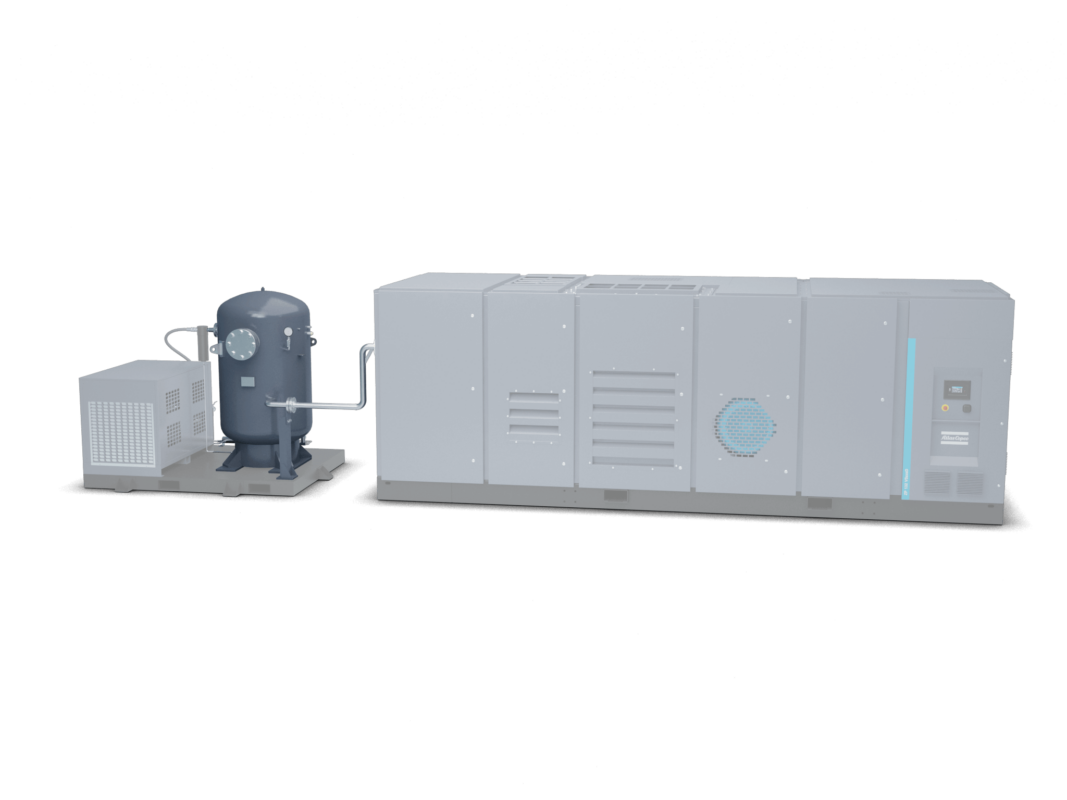

Silent, compact plug and play solution

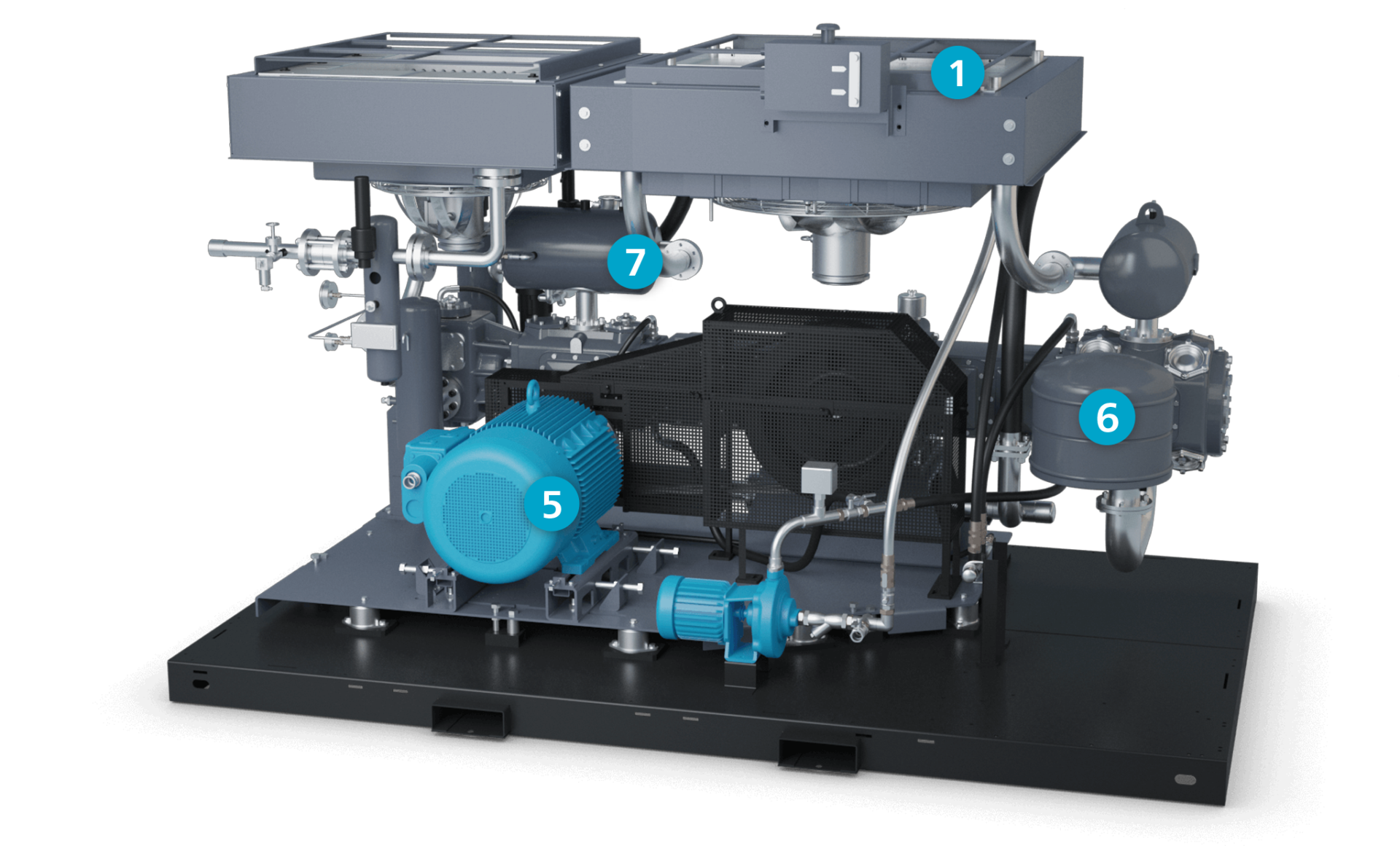

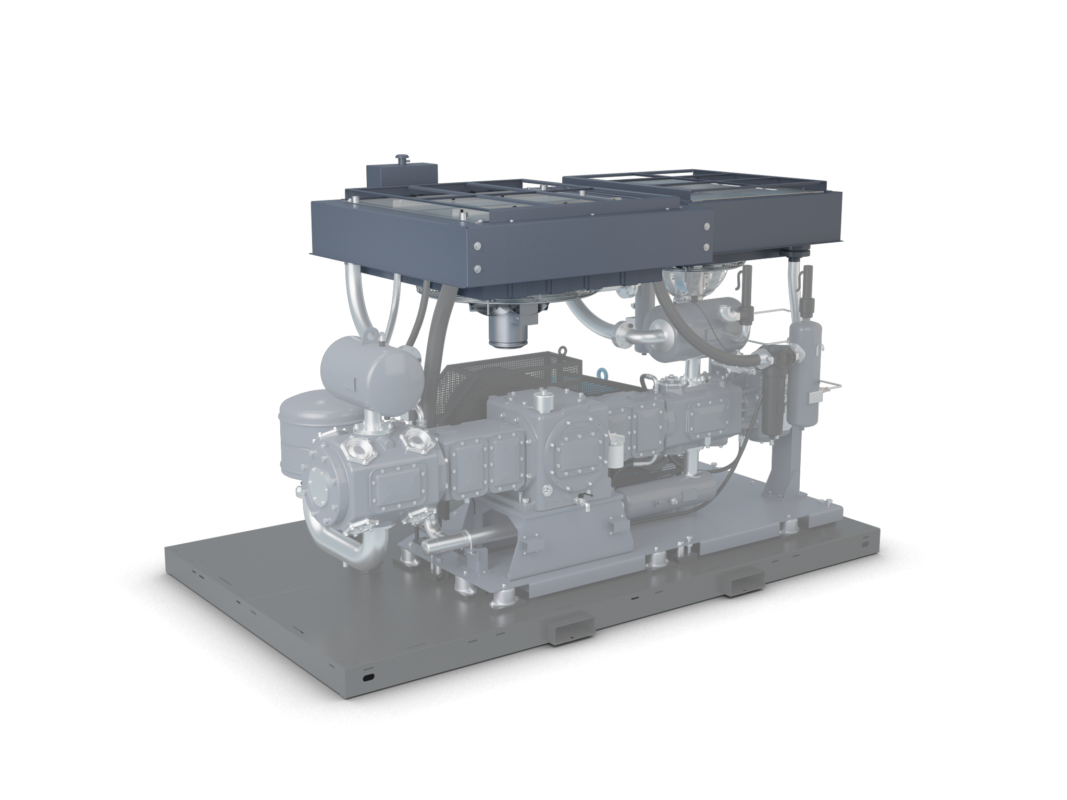

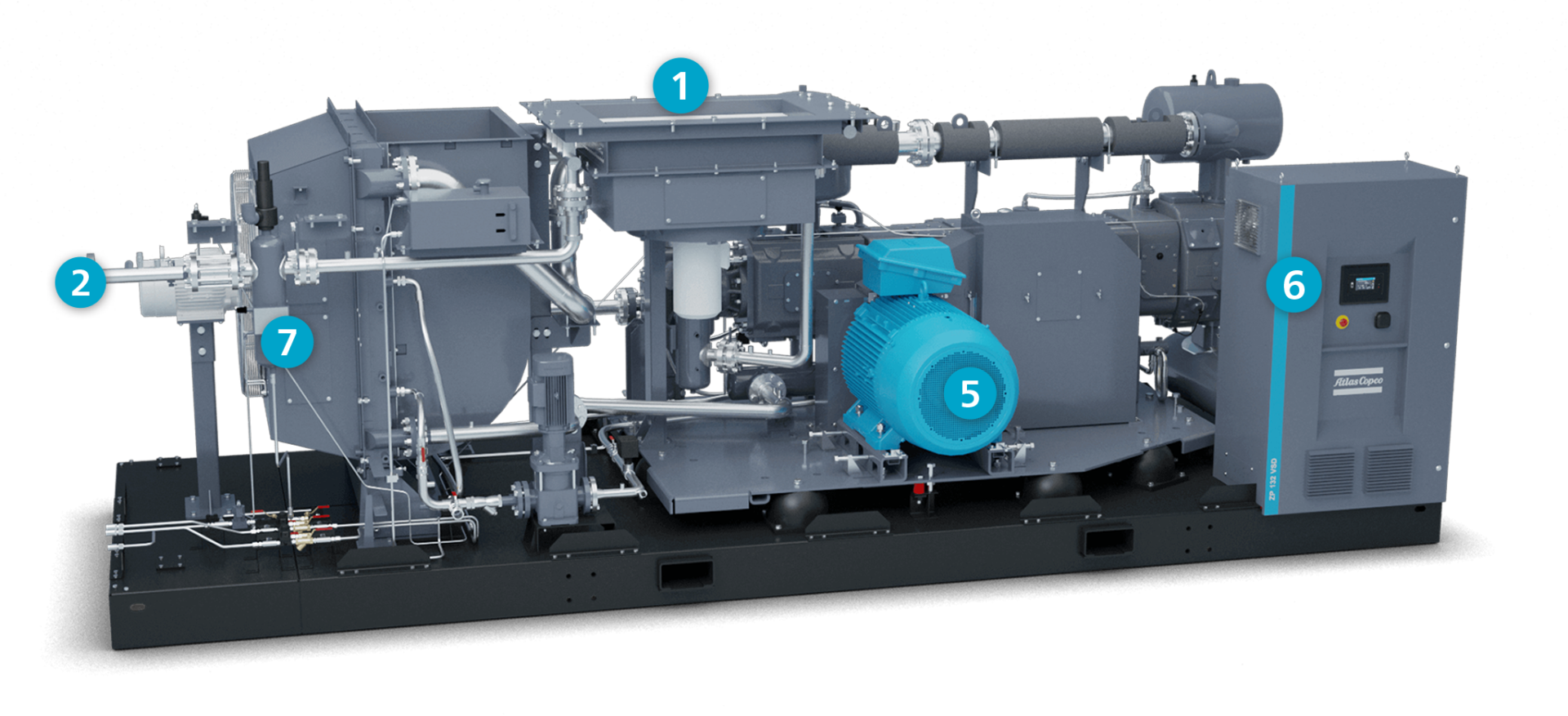

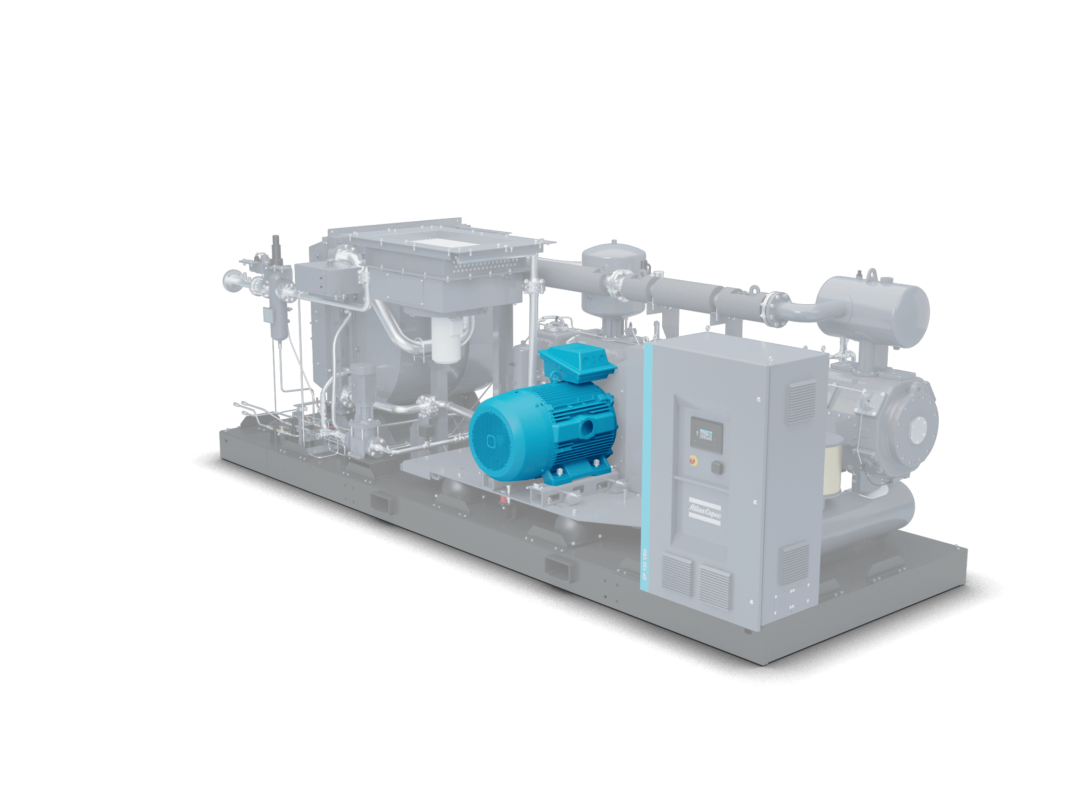

ZP 55

Right view

Left view

-

1

Unique cooler assembly

-

2

Plug and play solution

-

3

Setting a new standard with the rod drop technology

-

4

Oil-free air piston technology

-

5

Efficient drive system with IE3 motors

-

6

Advanced monitoring system

-

7

Low noise level

-

1

Unique cooler assembly

The only manufacturer using air cooled technology suitable for 50°C ambient environment. These coolers eliminate the need to install accessories such as cooling water tower, cooling water. pump, make up water and interconnecting piping. Fast installation, low floor space, no maintenance for accessories.

-

2

Plug and play solution

Horizontal BOP design and dynamically balanced arrangements leads to lesser vibration levels. This machine comes with unique base frame design & special elastomer anti-vibration mounts, needing no special foundation.

-

3

Setting a new standard with the rod drop technology

The only manufacturer to integrate sensors to optimize the availability of the machine, leading to increased reliability and lower maintenance costs.

-

4

Oil-free air piston technology

Completely oil-free chambers with PTFE piston rings & long distance pieces with wiper rings.

No risk of contamination, damaged products or losses from operational downtime.

Reduced maintenance costs as there is no need for oil filtration.

-

5

Efficient drive system with IE3 motors

The standard machine comes fitted with the premium efficiency IE3 TEFC motor, suitable to operate at 50 °C ambient condition. These continuous duty motors run at low speeds, designed for longer life. Intelligent 3 part belt guard design ensures easy assembly and maintenance.

-

6

Advanced monitoring system

User-friendly Elektronikon® with enhanced connectivity potential.

Integrated smart algorithms to optimize system pressure and maximize energy efficiency.

Included warning indications, maintenance scheduling and online visualization of the machine’s condition.

-

7

Low noise level

The closed canopy drastically reduces the noise level compared to piston compressors which increases the working comfort.

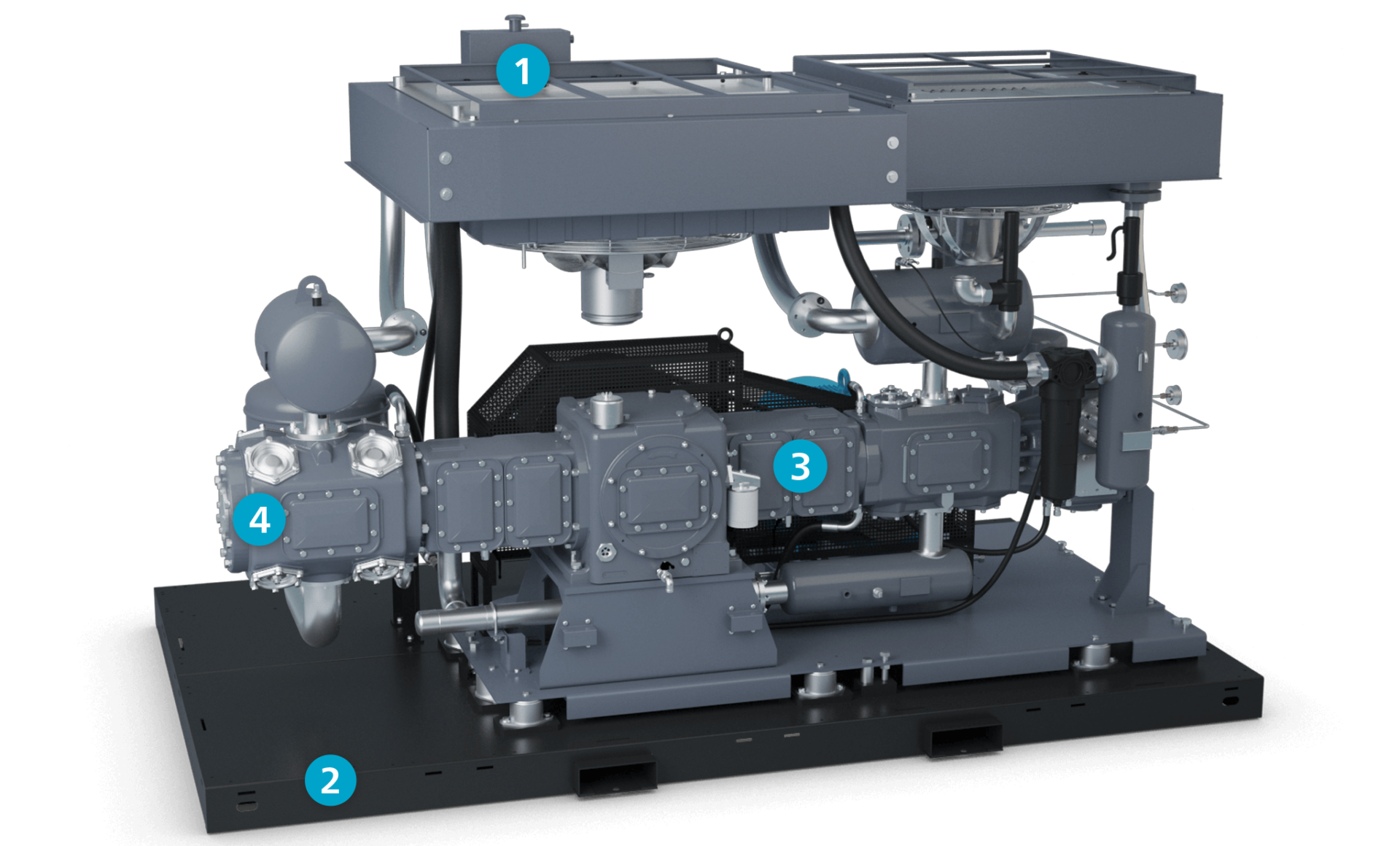

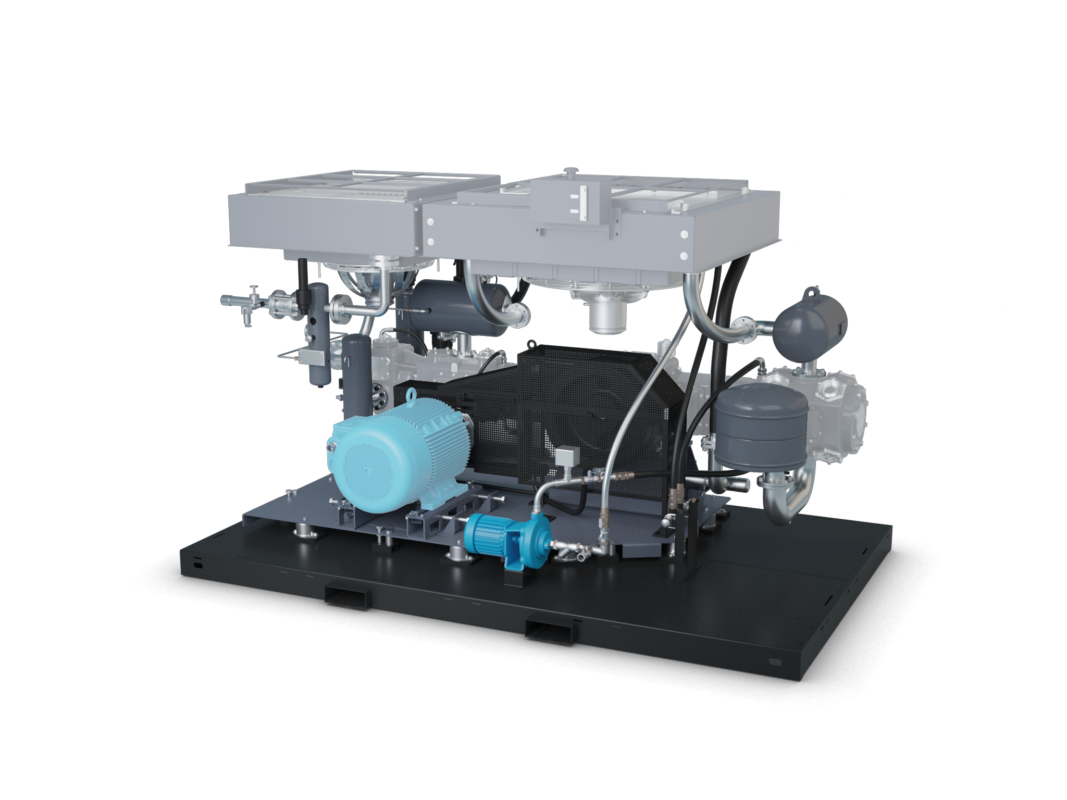

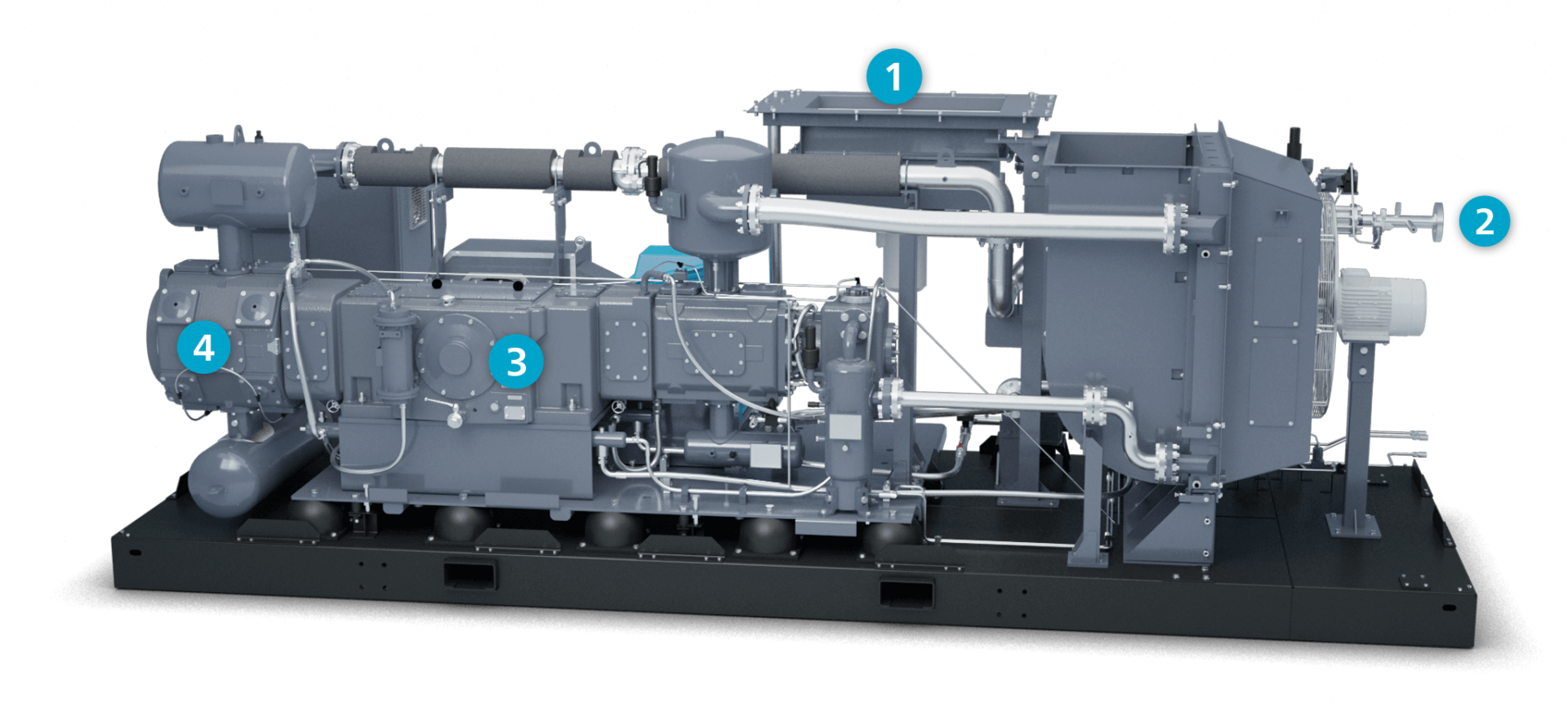

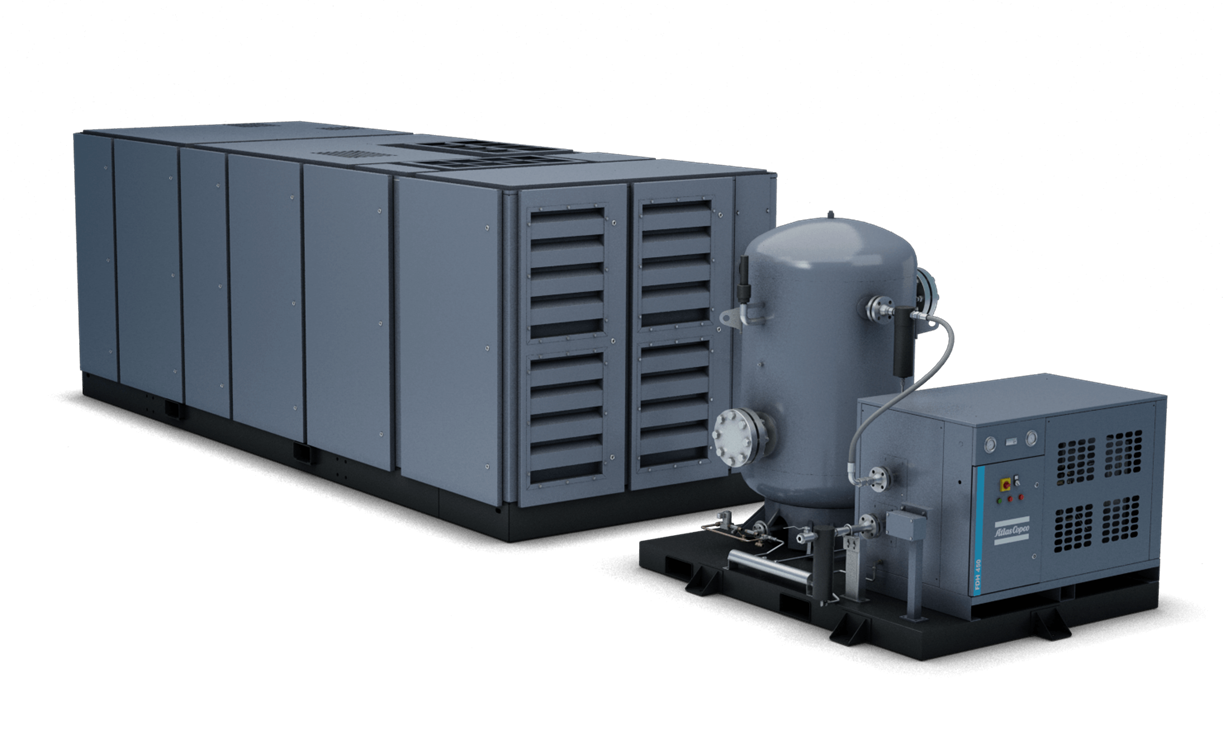

ZP 132

Right view

Left view

-

1

Unique cooler assembly

-

2

Plug and play solution

-

3

Setting a new standard with the rod drop technology

-

4

Oil-free air piston technology

-

5

Efficient drive system with IE3 motors

-

6

Advanced monitoring system

-

7

Low noise level

-

1

Unique cooler assembly

The only manufacturer using air cooled technology suitable for 50°C ambient environment. These coolers eliminate the need to install accessories such as cooling water tower, cooling water. pump, make up water and interconnecting piping. Fast installation, low floor space, no maintenance for accessories.

-

2

Plug and play solution

Horizontal BOP design and dynamically balanced arrangements leads to lesser vibration levels. This machine comes with unique base frame design & special elastomer anti-vibration mounts, needing no special foundation.

-

3

Setting a new standard with the rod drop technology

The only manufacturer to integrate sensors to optimize the availability of the machine, leading to increase reliability and lower maintenance costs.

-

4

Oil-free air piston technology

Completely oil-free chambers with PTFE piston rings & long distance pieces with wiper rings.

No risk of contamination, damaged products or losses from operational downtime.

Reduced maintenance costs as there is no need for oil filtration.

-

5

Efficient drive system with IE3 motors

The standard machine comes fitted with the premium efficiency IE3 TEFC motor, suitable to operate at 50 °C ambient condition. These continuous duty motors run at low speeds, designed for longer life. Intelligent 3 part belt guard design ensures easy assembly and maintenance.

-

6

Advanced monitoring system

User-friendly Elektronikon® with enhanced connectivity potential.

Integrated smart algorithms to optimize system pressure and maximize energy efficiency.

Included warning indications, maintenance scheduling and online visualization of the machine’s condition.

-

7

Low noise level

The closed canopy drastically reduces the noise level compared to piston compressors which increases the working comfort.

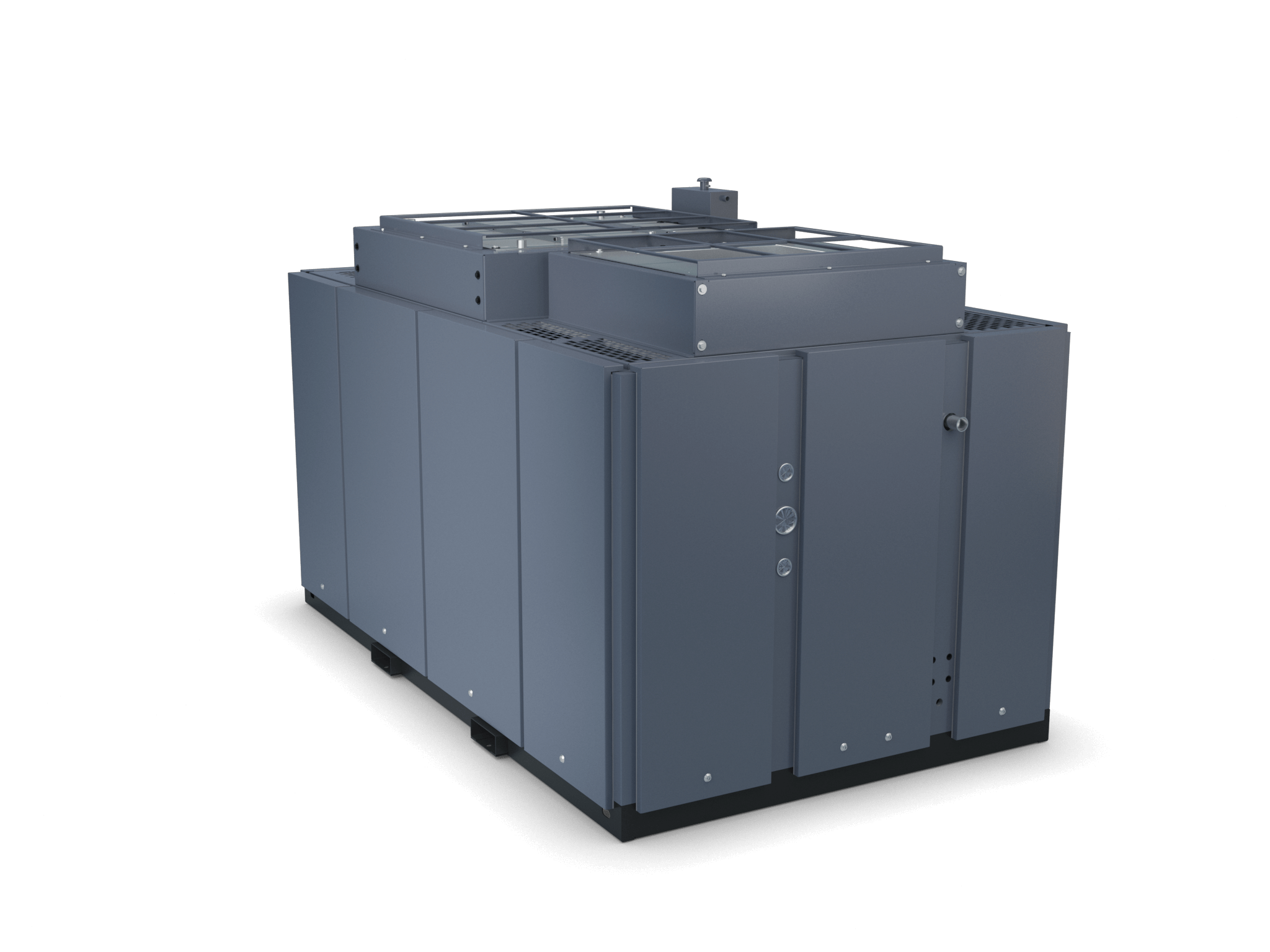

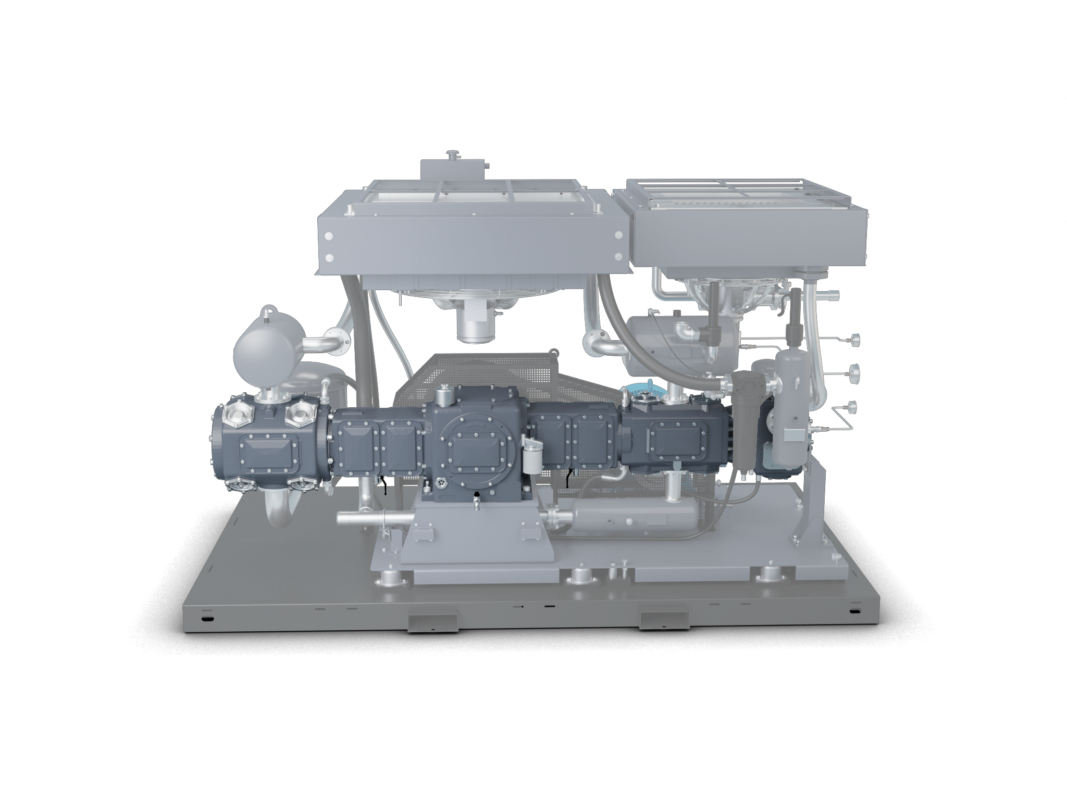

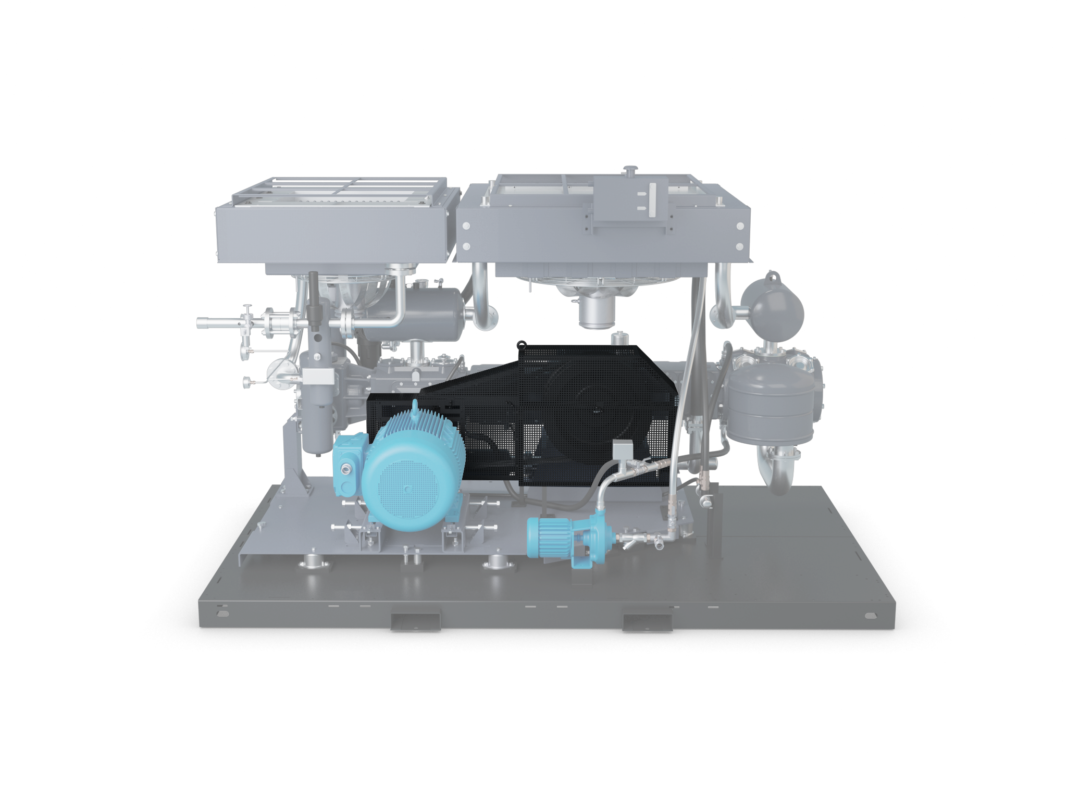

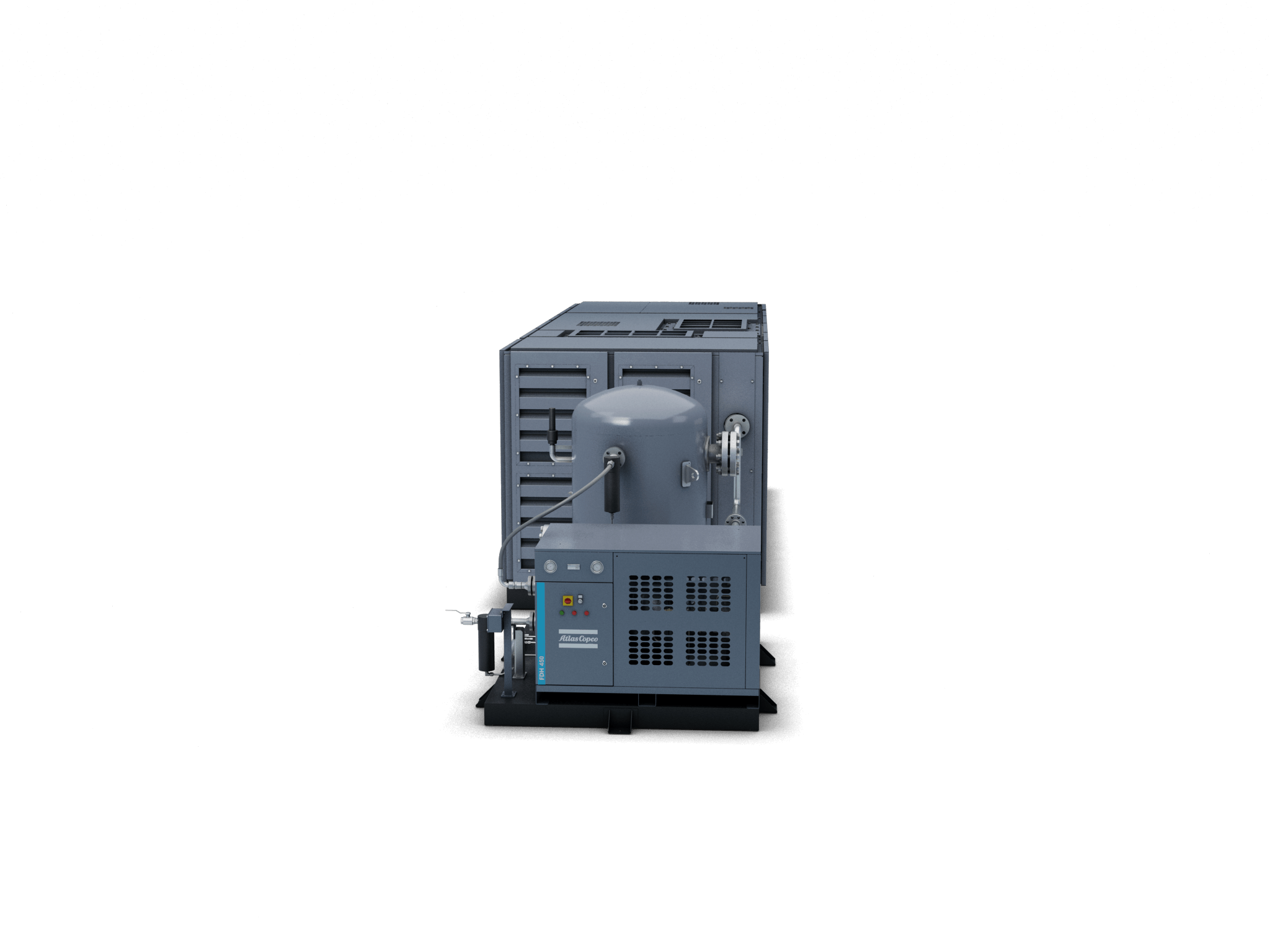

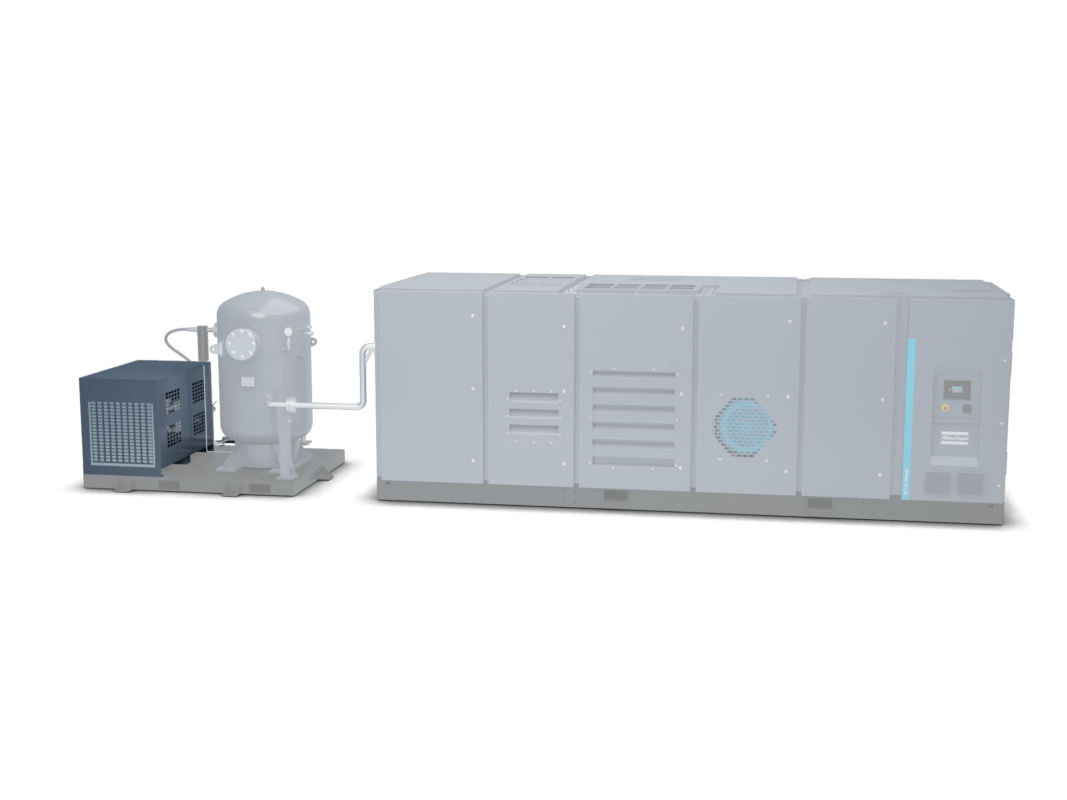

ZP 132 FF

Front view

Back view

-

1

Cooler

-

2

Plug & play

-

3

New technology

-

4

OFA piston

-

5

Drive

-

6

Monitoring

-

7

Low noise

-

8

FF = Full Feature

-

9

FDH dryer

-

10

HP vessel

-

1

Cooler

-

2

Plug & play

-

3

New technology

-

4

OFA piston

-

5

Drive

-

6

Monitoring

-

7

Low noise

-

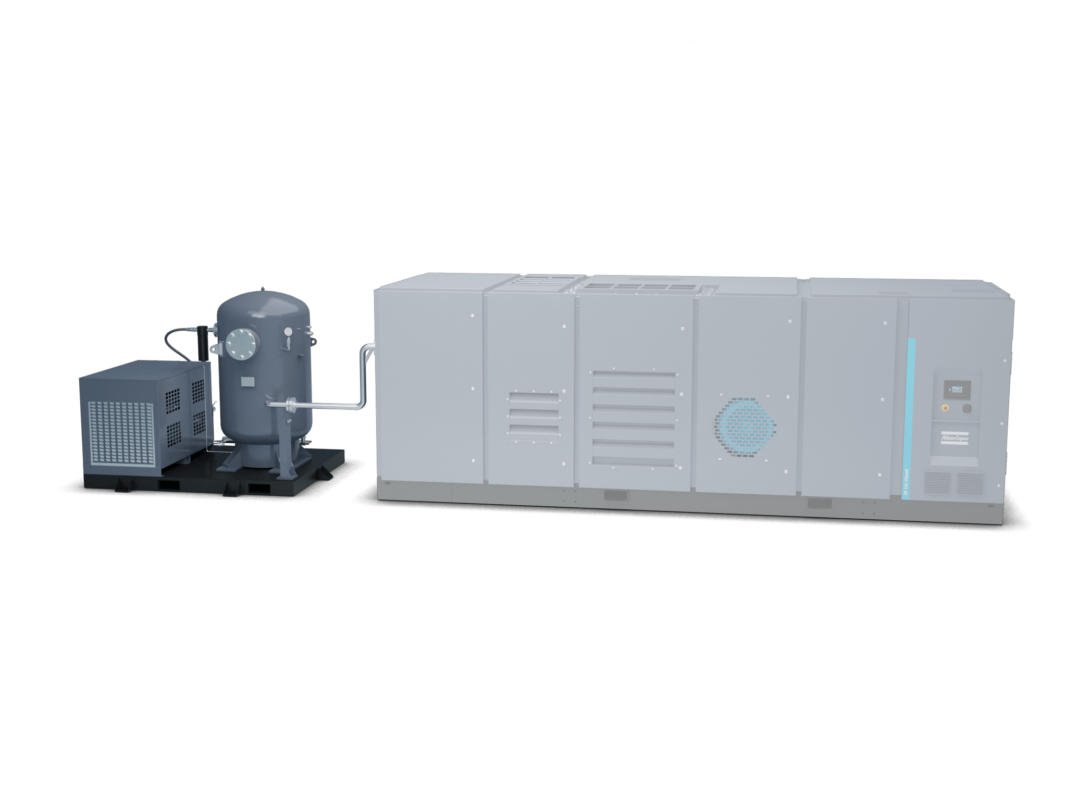

8

FF = Full Feature

All the sizes of ZP can be executed in Full Feature (FF) version to deliver dried and filtered high pressure air.

For easy assembly, the FF-part comes with all pipes and electrical connections included, this to maintain the Plug&Play concept.

For easy transport, installation and still maintain flexibility, the FF part comes on it’s own skid, which can be installed straight after the ZP or under a 90° angle.

-

9

FDH dryer

On the FF part, there is a fully inhouse build and designed High Pressure refrigerant dryer, called FDH

Thanks to the stainless Steel Heat exchangers, including and Air-Air part and Air-refrigerant part, the final outlet air achieves dewpoints down to 3° C and a Relative Humidity below 50%

With the selected refrigerant, the FDH dryer is able to be used to higher ambient temperatures, even up to 50° C

-

10

HP vessel

Removing pulsations and improving regulation performance are the 2 reasons on why a vessel is a must have on any piston compressor, which in case of the FF-version, this is included in the scope

Vessel is suitable for high pressure and adequately sized for the functions. Additionally, it comes with drain at the bottom to remove condensation that is not taken out already