Over 80% of a compressor’s lifecycle cost is taken up by the energy it consumes. Moreover, the generation of compressed air can account for more than 40% of a plant’s total electricity bill. The ZR/ZT is not only designed for reliability, but also for efficiency. Our unique and patented elements are designed in-house for maximum efficiency. The superior rotor coating, compact rotor profiles and cooling jackets guarantee maximum compression efficiency. The unique Z seal design guarantees efficient and 100% certified oil-free air for your application.

Highest efficiency

Designed for VSD

Compressors don’t always run at full load, because your application often has a varying air demand. Atlas Copco’s VSD technology closely follows the air demand by automatically adjusting the motor speed. This results in large energy savings of up to 35%. The elements of the ZR/ZT are designed for VSD machines to run efficiently at the broadest possible range. For this unit we also designed our own NEOS inverter to constantly optimize the motor speed and our own Permanent Magnet Motor for class-leading efficiency.

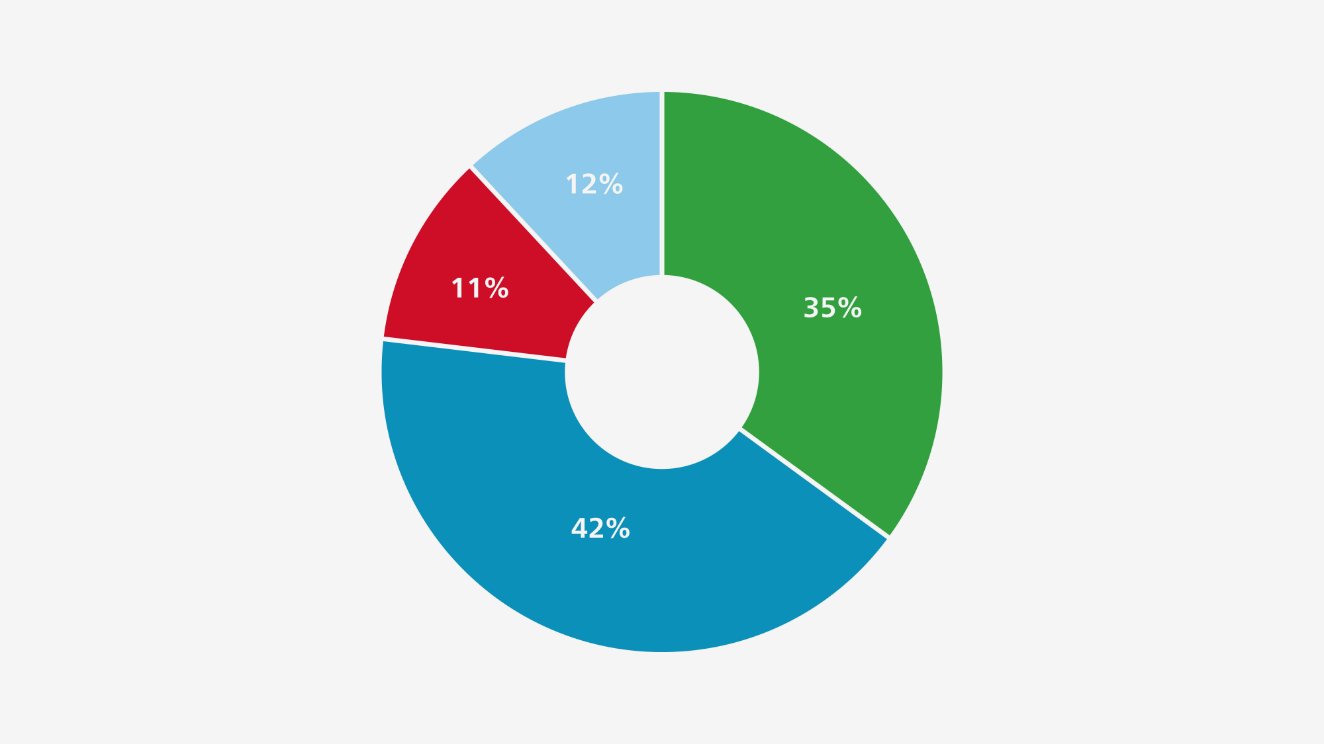

Energy cost: 42%

Energy savings with VSD: 35%

Investment: 12%

Maintenance: 11%

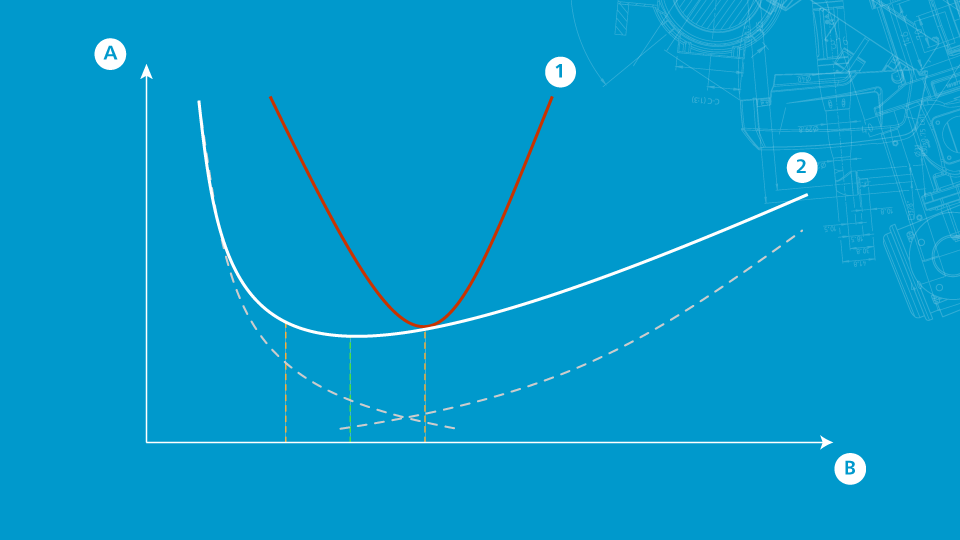

A = Losses

B = Speed

1 = Total losses traditional element

2 = Total losses AC element

VSD⁺ concept

The ZR/ZT VSD⁺ range with its dual NEOS drives has the widest operating range on the market today. These units can operate from 11 to 100% load without wasting energy from unloaded operation, resulting in huge energy savings during periods of low to medium air demand. Another advantage of the dual NEOS drives is that the ZR/ZT VSD⁺ always works at optimal efficiency at any pressure, when comparing to standard fixed speed and VSD machines that have a fixed gear ratio.

Optimized air flow in the machine

The ZR/ZT 200-355 VSD⁺ brings cool dense air into the package for optimal compression efficiency. The piping and components are strategically placed to minimize the pressure drop in the package, leading to optimal efficiency. The coolers have been carefully designed to keep the pressure drop at a bare minimum. Our zero loss drains account for zero waste of compressed air, making the ZR/ZT VSD⁺ the most efficient machine on the market.

Elektronikon® Mk5 Touch control

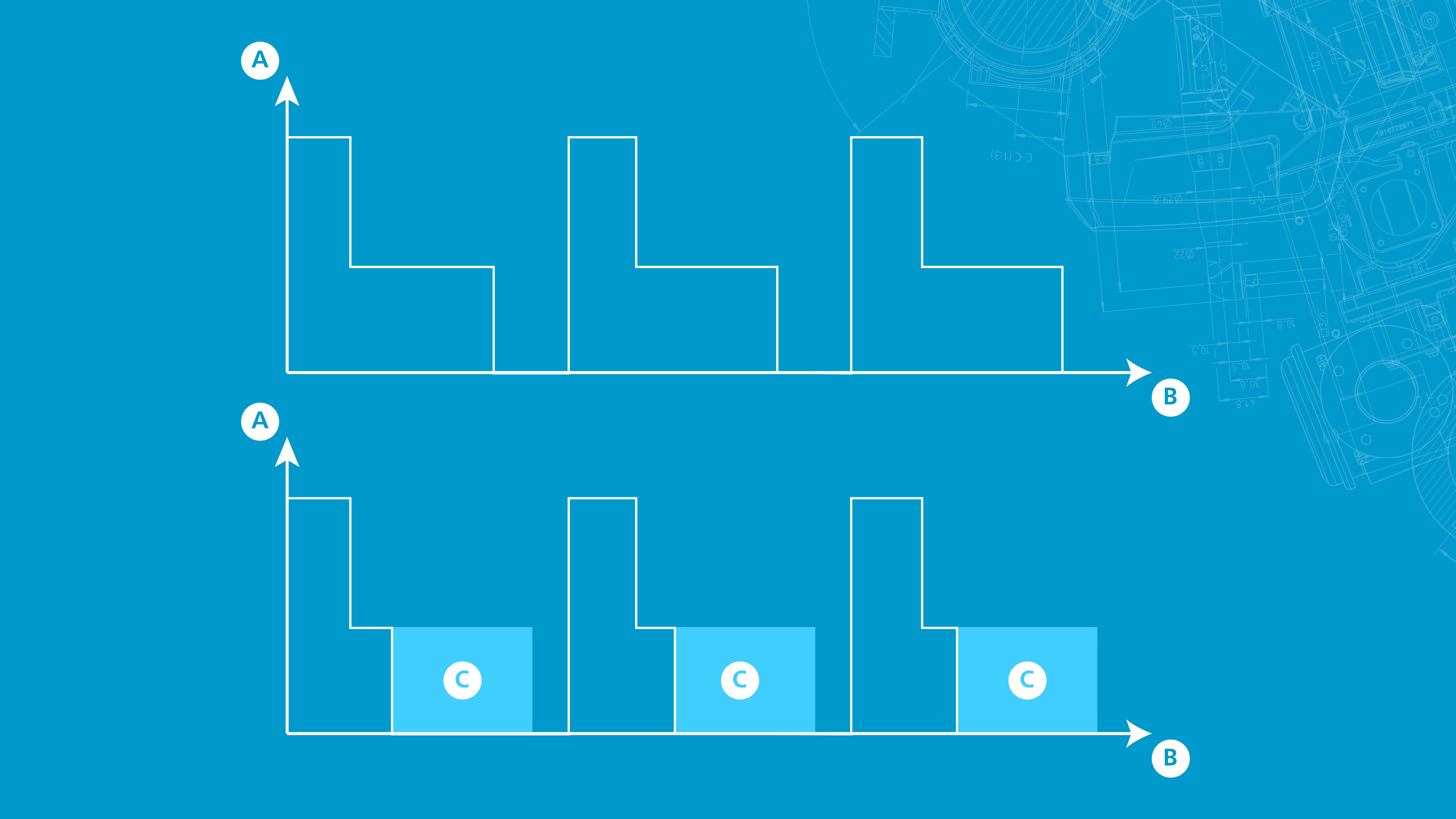

80% of your costs with a compressor come from energy consumption. The Elektronikon® compressor monitoring system saves energy by using:

- Delayed second stop to stop the compressor whenever possible.

- Dual pressure band for lower pressure in the systems during weekends and nights.

- Automatic main motor speed adjustments depending on air demand.

- Adapting dryer speed according to your needs.

A = Power consumption

B = Time

C = Energy savings

SMARTLINK

- Monitor your compressed air installation with SMARTLINK: Knowing the status of your compressed air equipment at all times is the surest way to achieve optimal efficiency and maximum availability.

- Go for energy efficiency: customized reports on the energy efficiency of your compressor room.

- Increase uptime: all components are replaced on time, ensuring maximum uptime.

- Save money: early warnings avoid breakdowns and production loss.