Introducing the Atlas Copco ZR/ZT 200-355 VSD⁺, where efficiency meets reliability and sustainability. This air compressor is designed for industries demanding high compressed air quality standards.

Features & benefits

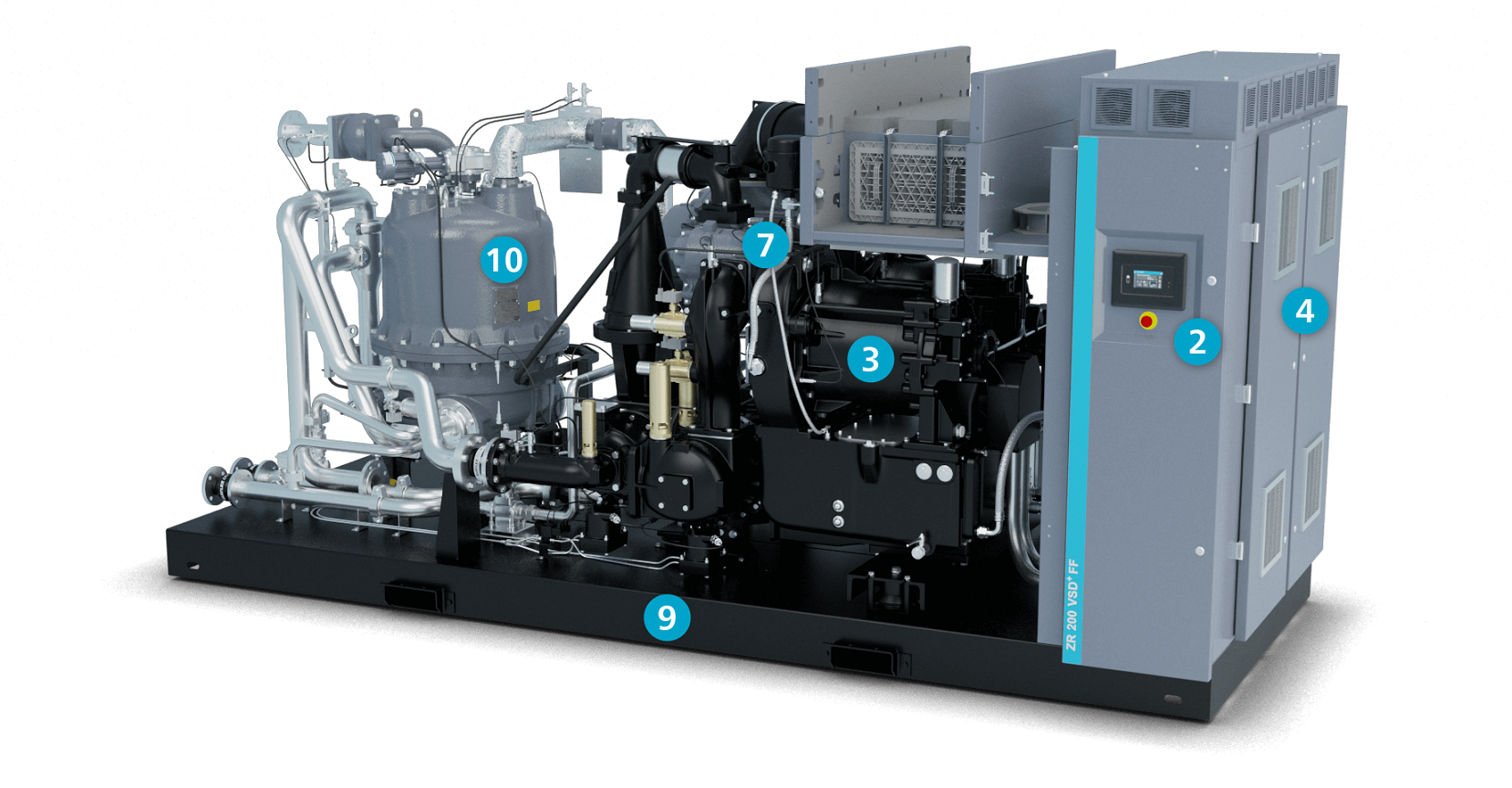

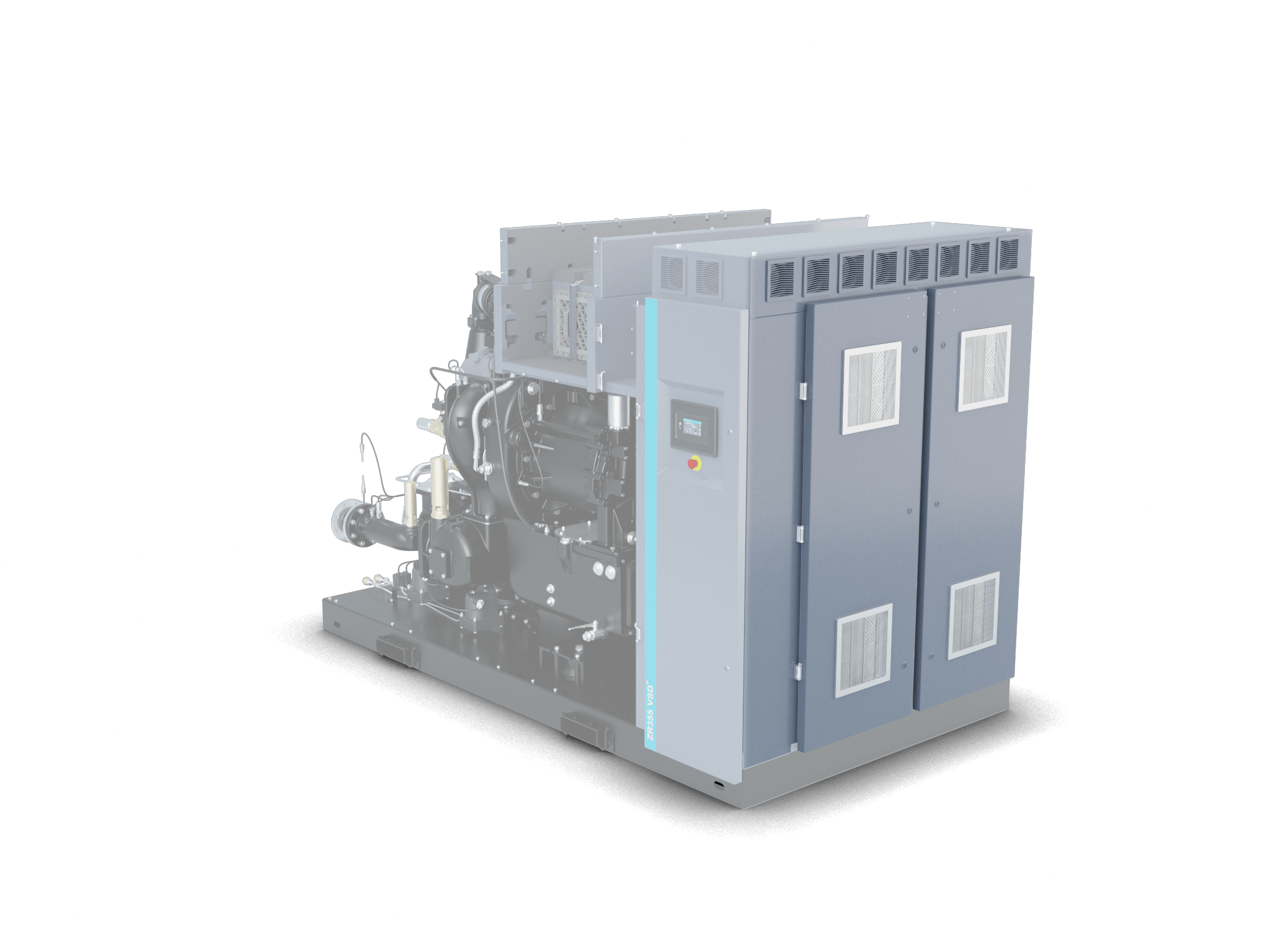

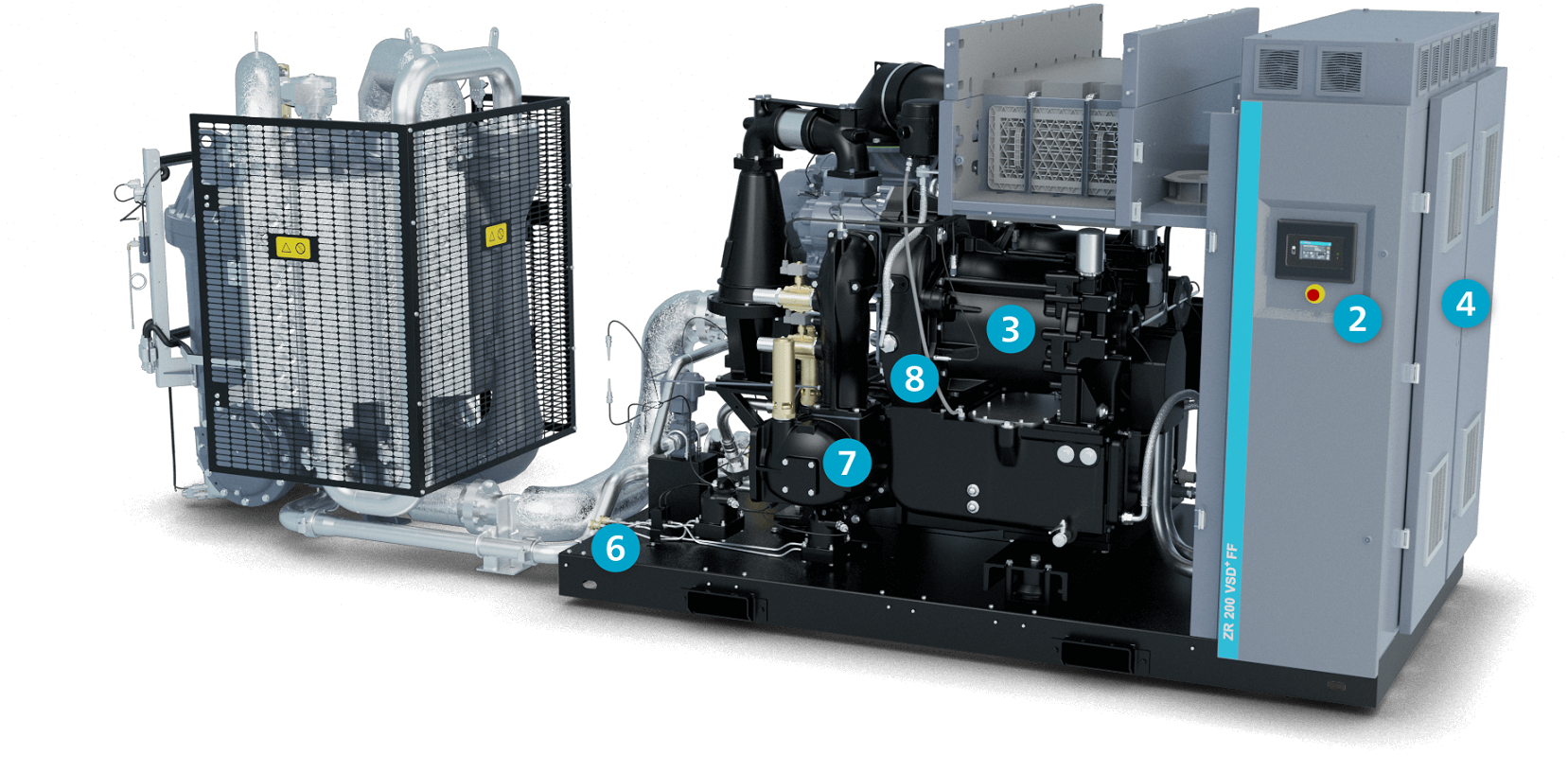

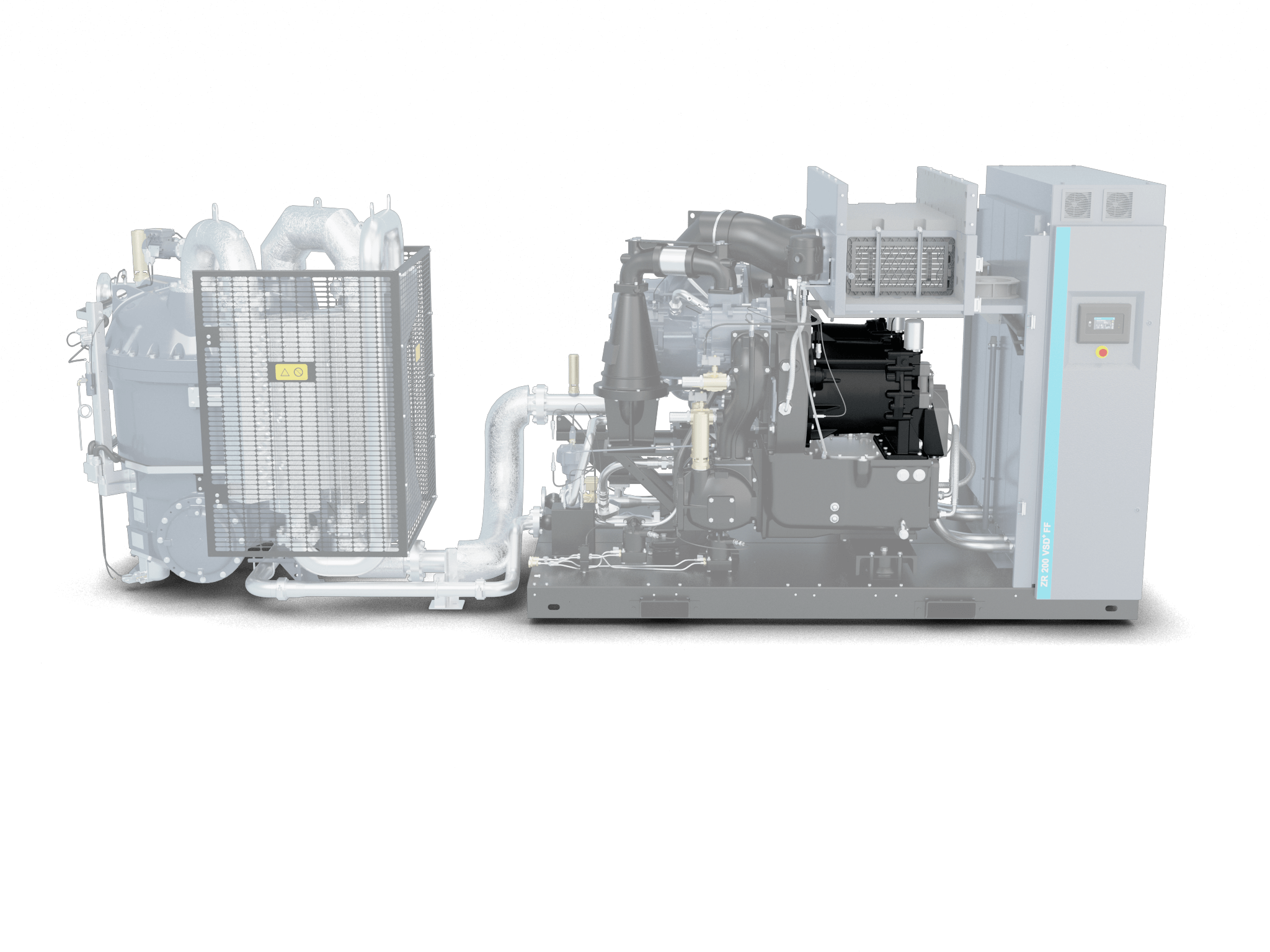

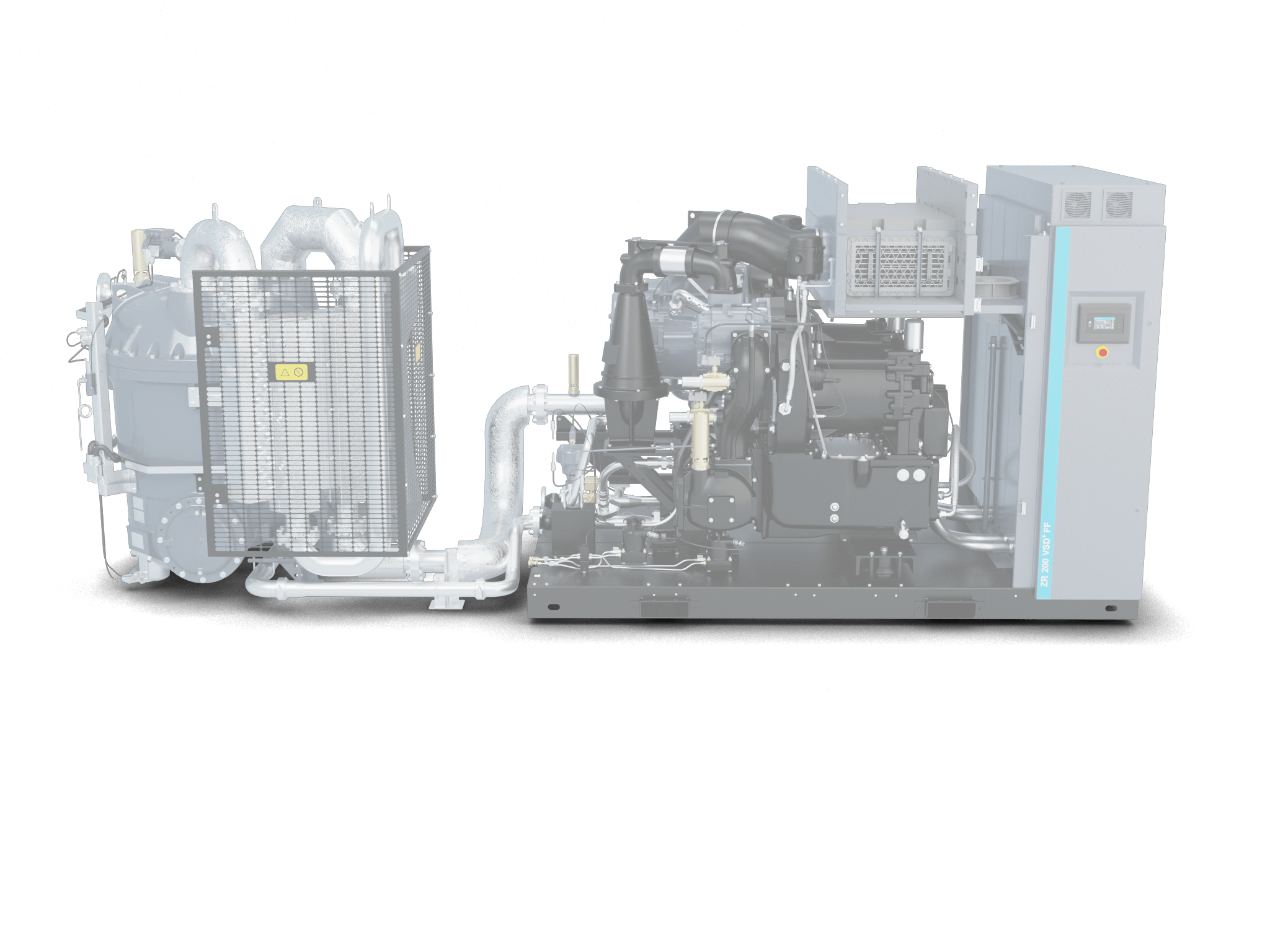

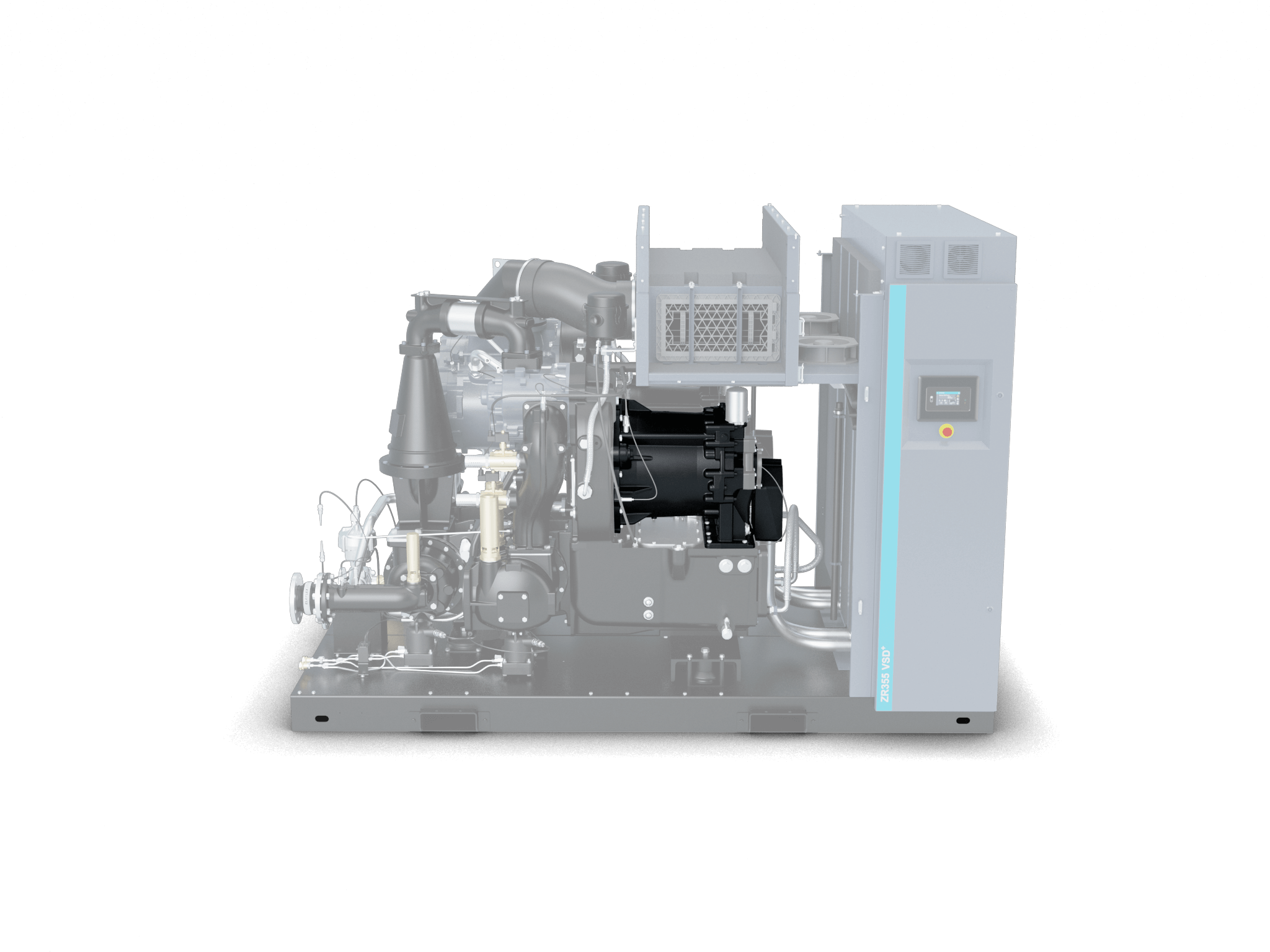

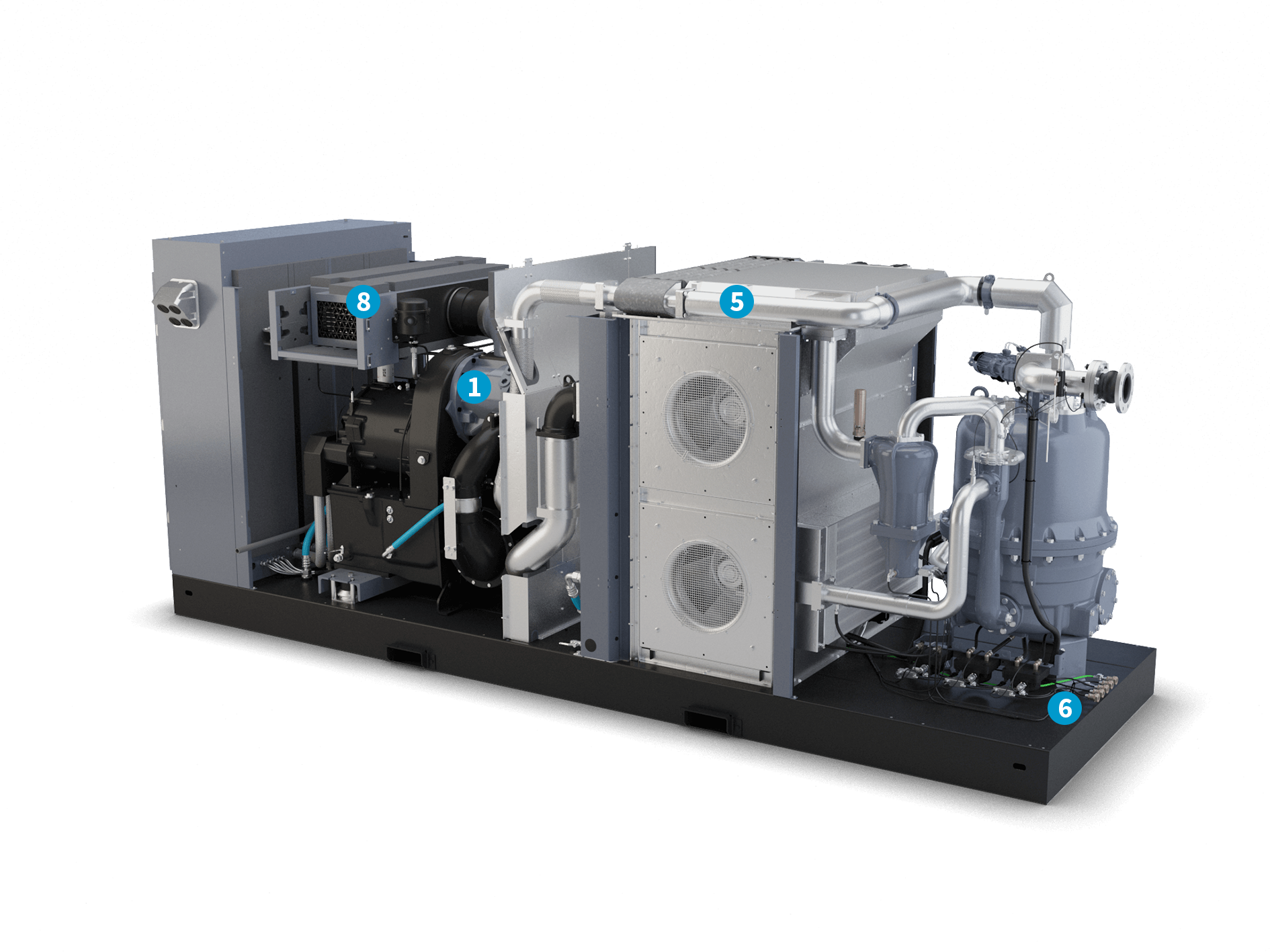

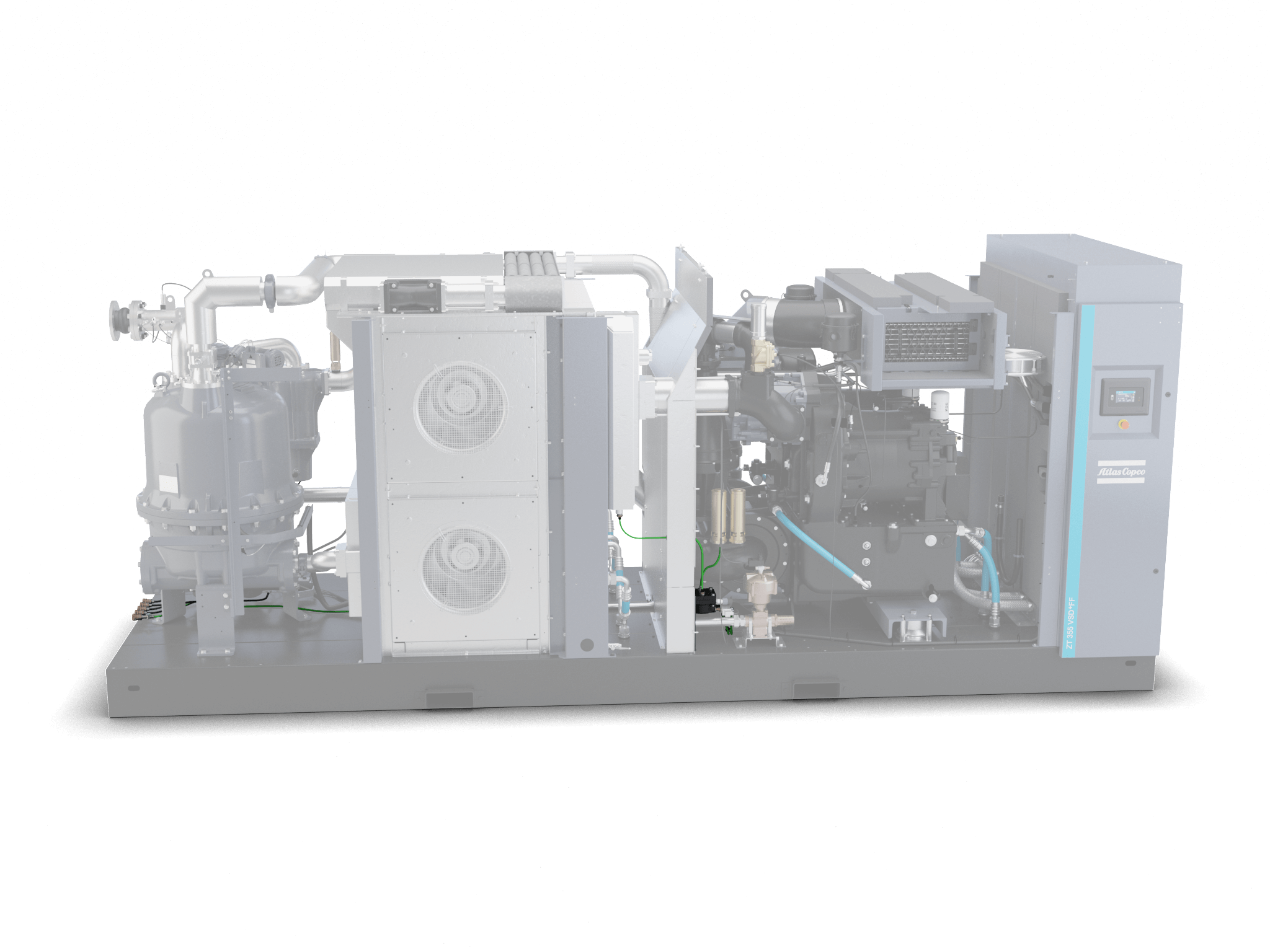

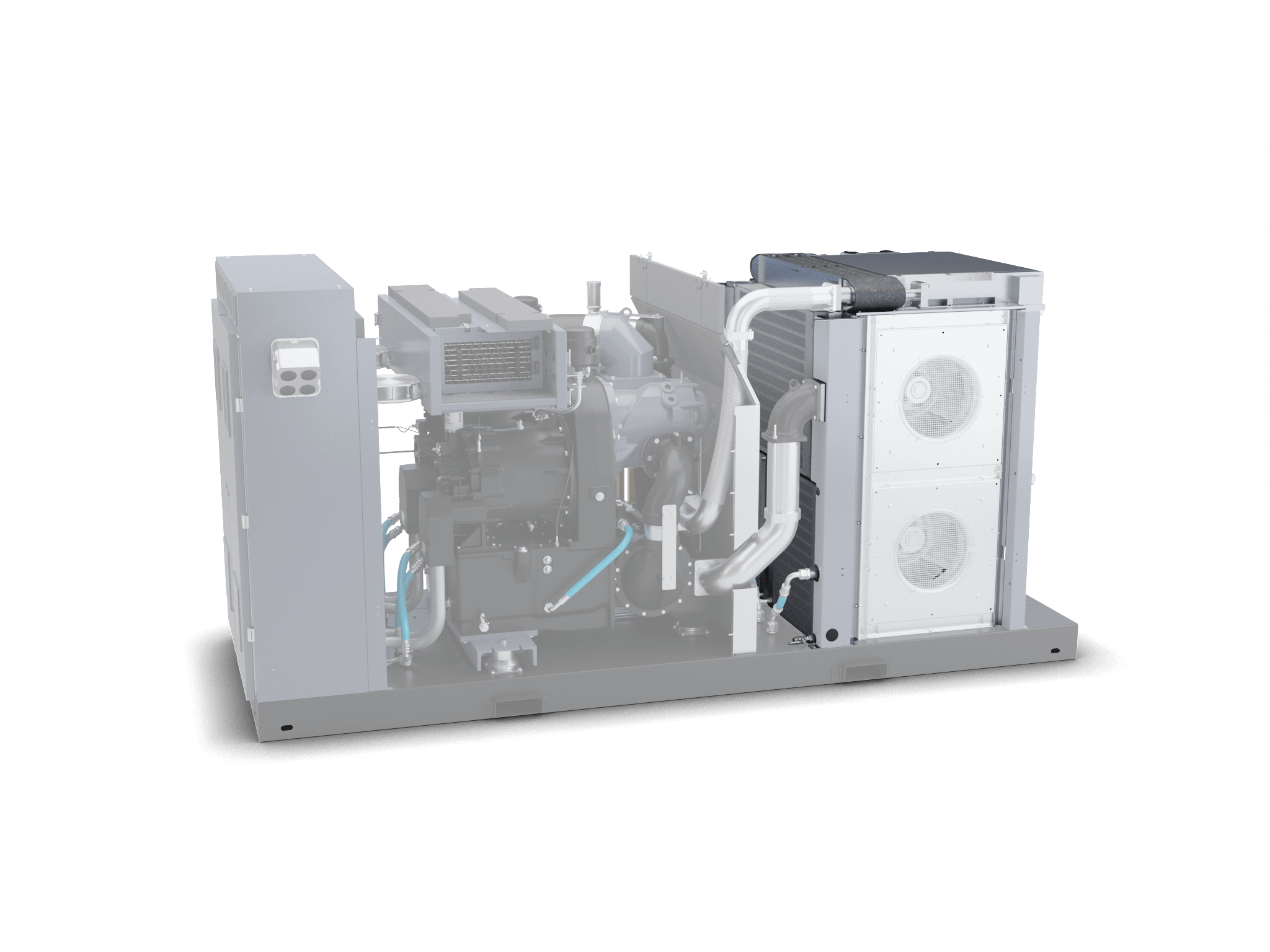

ZR 200-355 VSD⁺ FF (iMD)

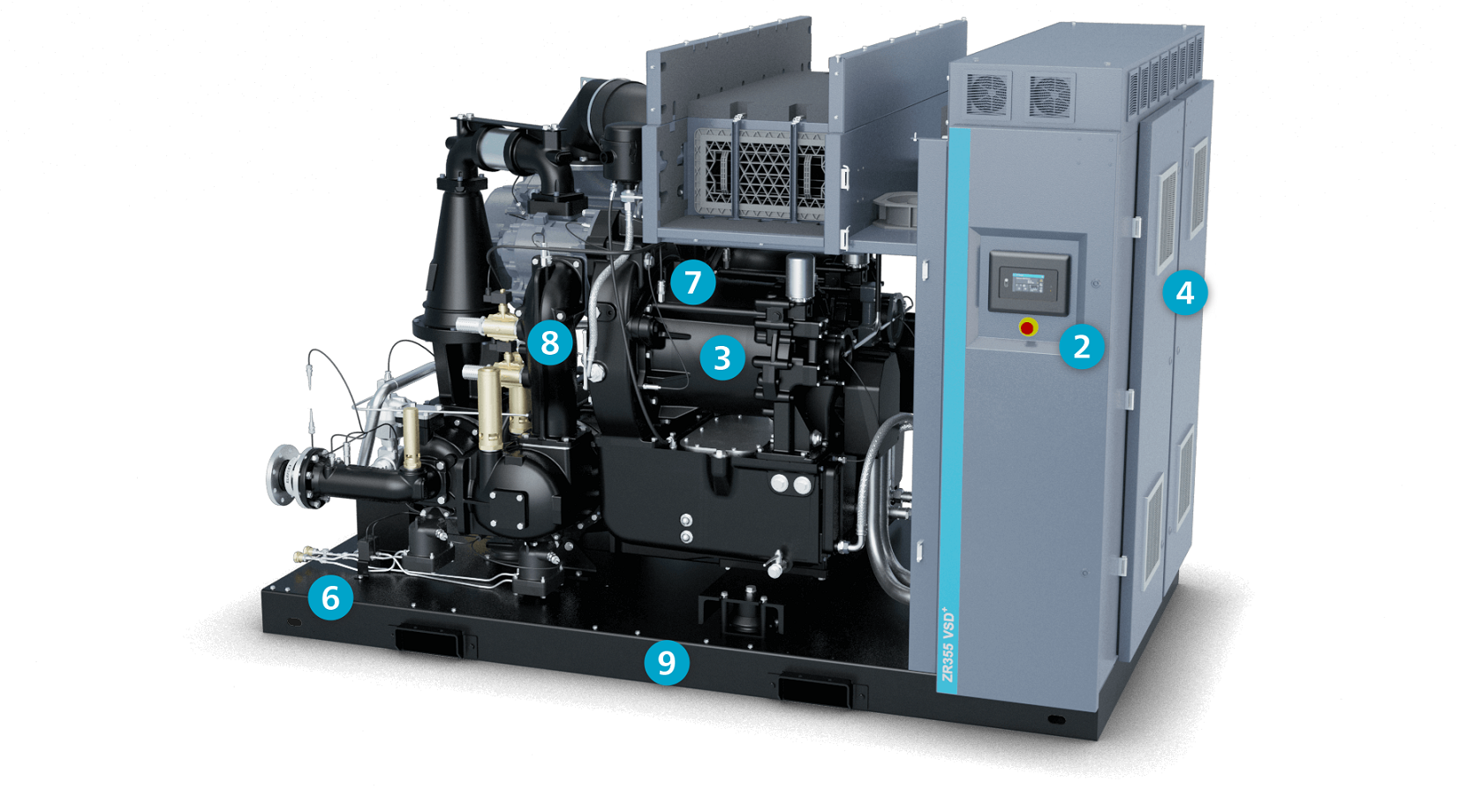

Product

On

Off

Labels

On

Off

Left view

Right view

-

1

High performance elements

-

2

Advanced touch screen monitoring system

-

3

Efficient motor

-

4

NEOS drive

-

5

Reliable cooling

-

6

Zero loss drains

-

7

Easy access

-

8

Soundproof design

-

9

Grouped service items

-

10

Integrated dryer

-

High performance elements

- Next generation world class compression element.

- Atlas Copco superior rotor coating for high durability.

- Thermal efficiency reduces the expansion leading to reduced wear and increased reliability.

- More compact, improved rotor profiles and cooling jackets for maximum durability.

-

Advanced touch screen monitoring system

- User-friendly Elektronikon® Touch, with enhanced connectivity potential.

- Included warning indications, maintenance scheduling and online visualization of the machine’s condition for increased reliability.

-

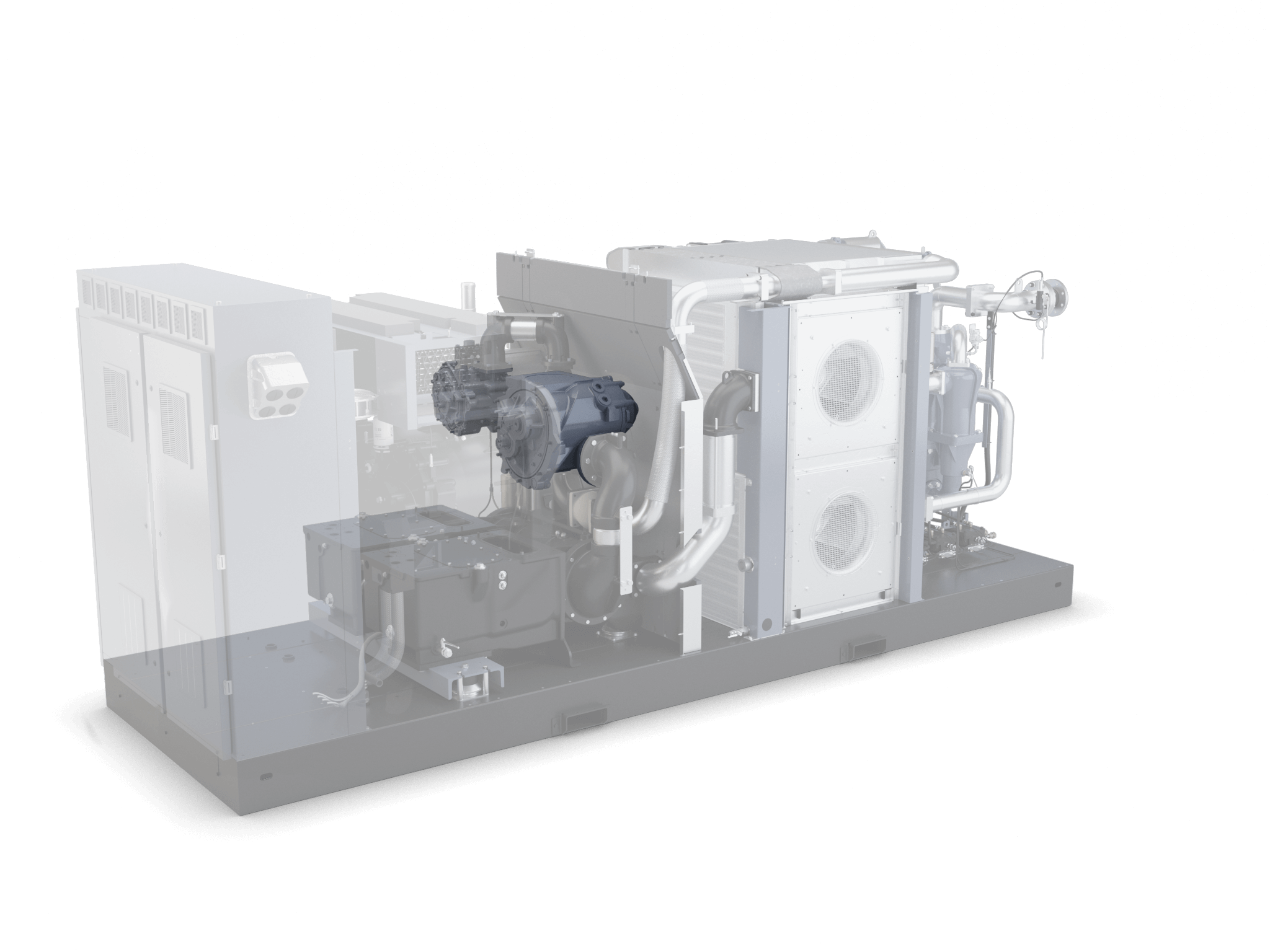

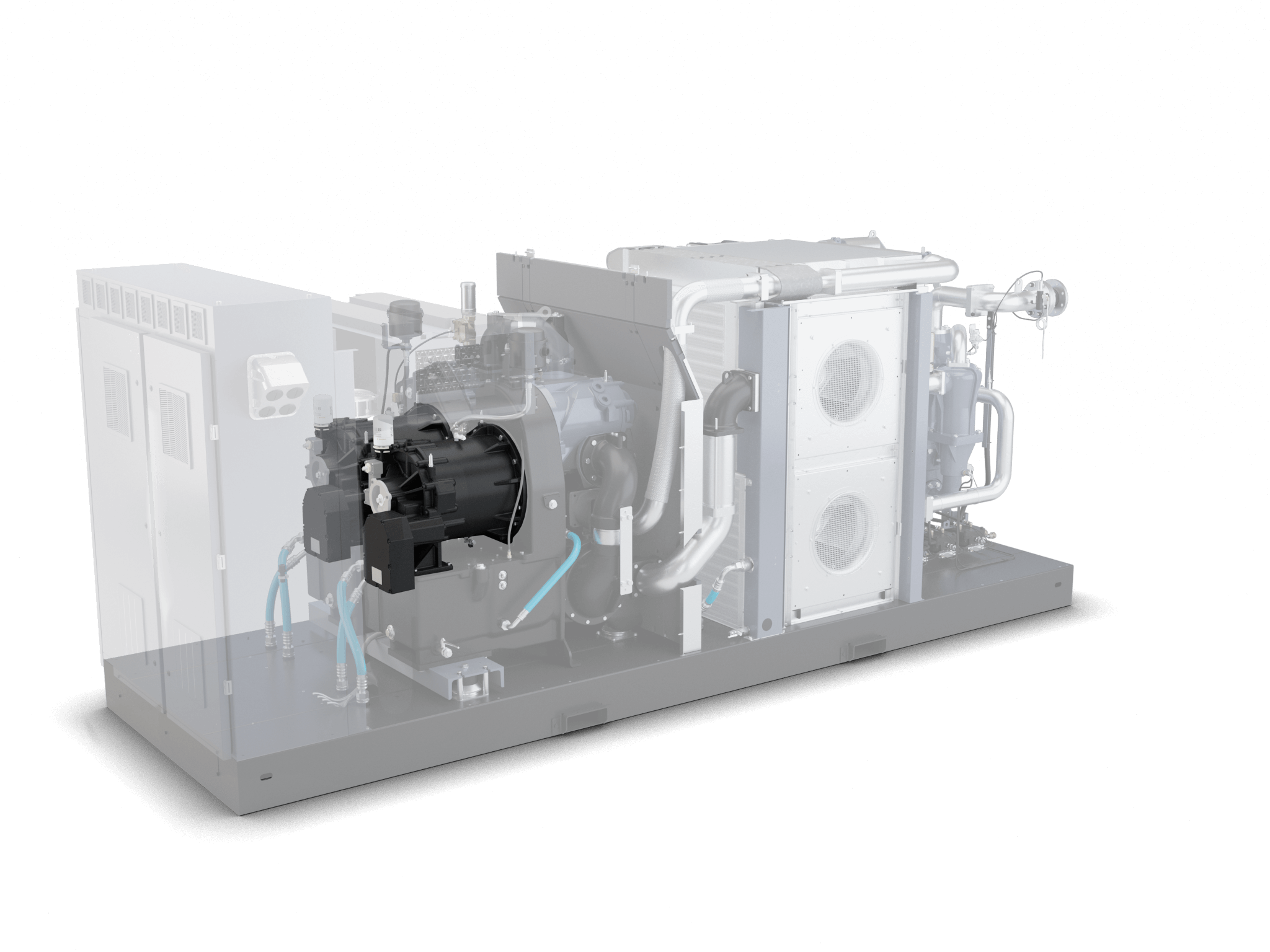

Efficient motor

- Permanent Magnet water cooled motor with oil lubricated bearings.

- Rock-solid reliability prevents dust and water entering the motor.

-

NEOS drive

- Atlas Copco NEOS inverter is designed to work in the harsh conditions of the compressor house.

- Modular design allows replacement of individual components, reducing maintenance cost.

- The cubicle keeps the inverter cool extending the lifetime & increasing operational efficiency.

-

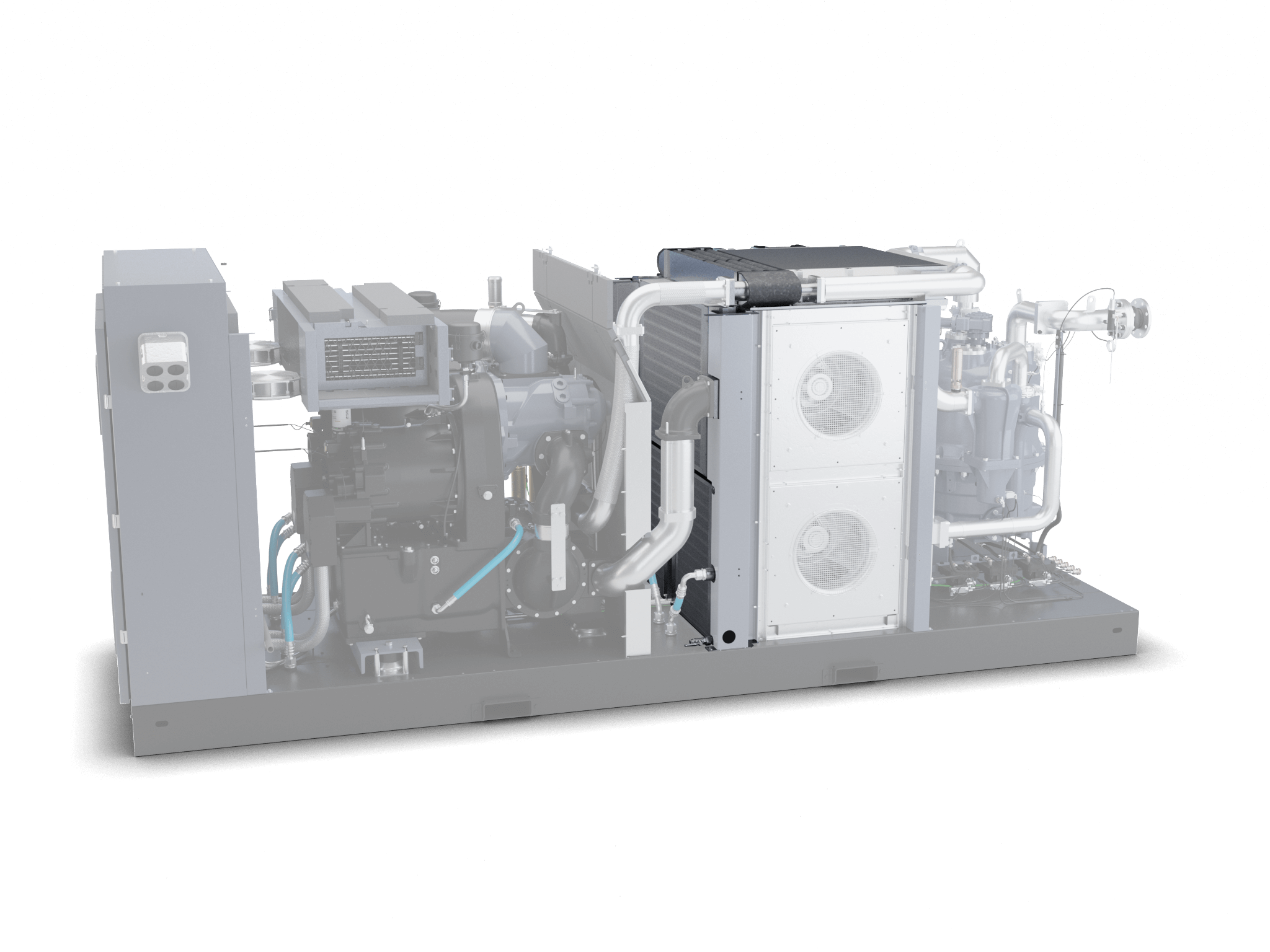

Reliable cooling

- Cooler with highly efficient water separator for higher reliability.

- Stainless steel enlarged surface coolers to ensure top performance over a long lifetime.

- Pipes with star profile form bi-anodised aluminium for preventing corrosion

- Easily removable for quick, cost-efficient maintenance.

-

Zero loss drains

- Clearance of all water & contamination.

- Increasing both product & system reliability.

-

Easy access

- Easy access to all components to minimize maintenance times.

- Hinged doors for easy routine maintenance eg. cleaning.

- Saves valuable and often expensive floor space in a facility.

- Highest ratio flow/footprint on the market.

-

Soundproof design

- Silenced canopy ensures optimal working conditions for everyone in the immediate environment.

- Optimized internal ducting and integrated pulsation damper to reduce the noise level.

- High quality coated canopy to prevent dust.

-

Grouped service items

- Minimal service time because service parts are grouped together for ease of access.

- All components are designed for serviceability and long lasting lifetime.

-

Integrated dryer

- Having an integrated dryer helps for easier installation, less pressure drop because of more efficient connections

- On top of that it also saves a lot of space in your compressor room.

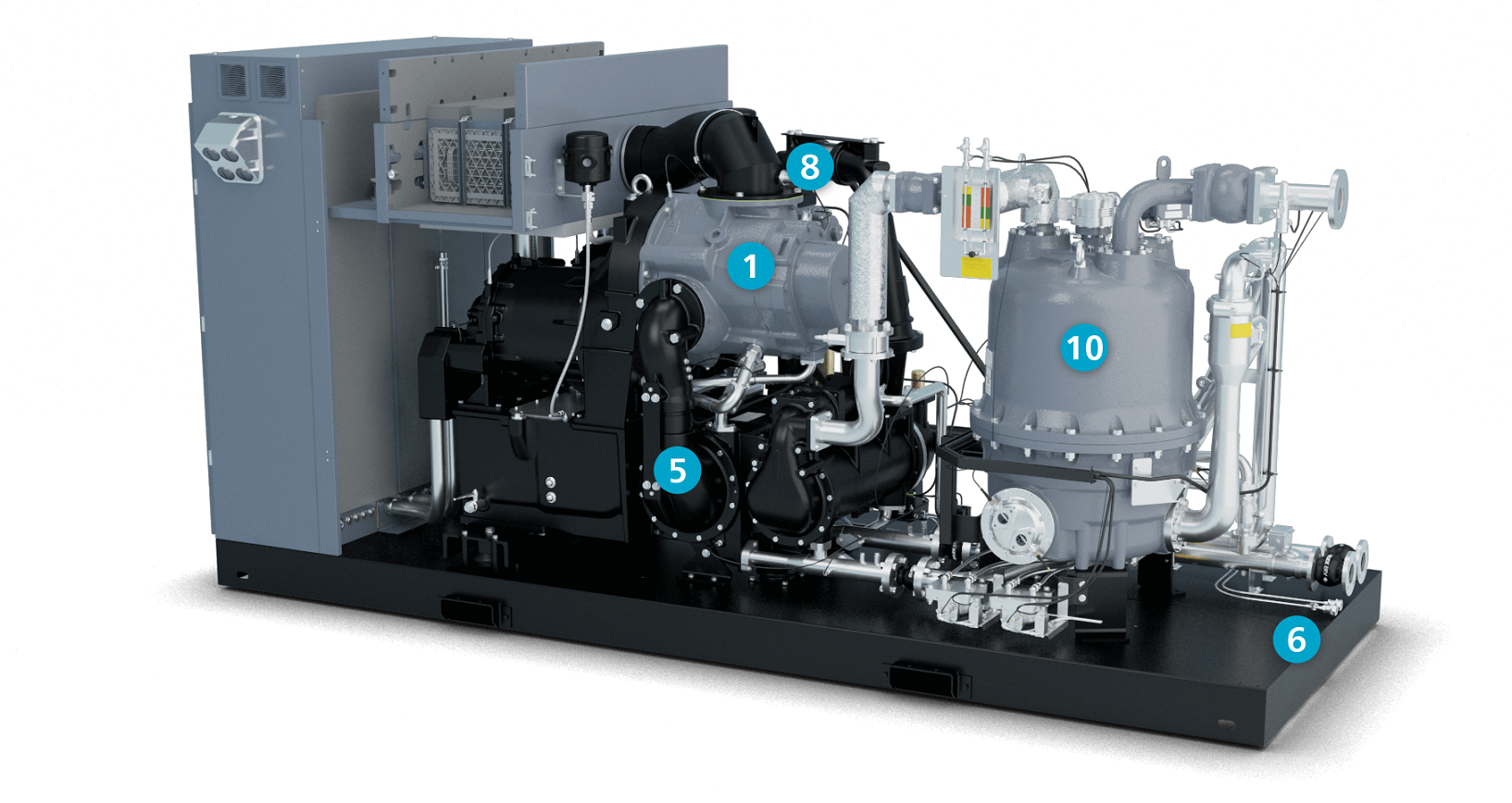

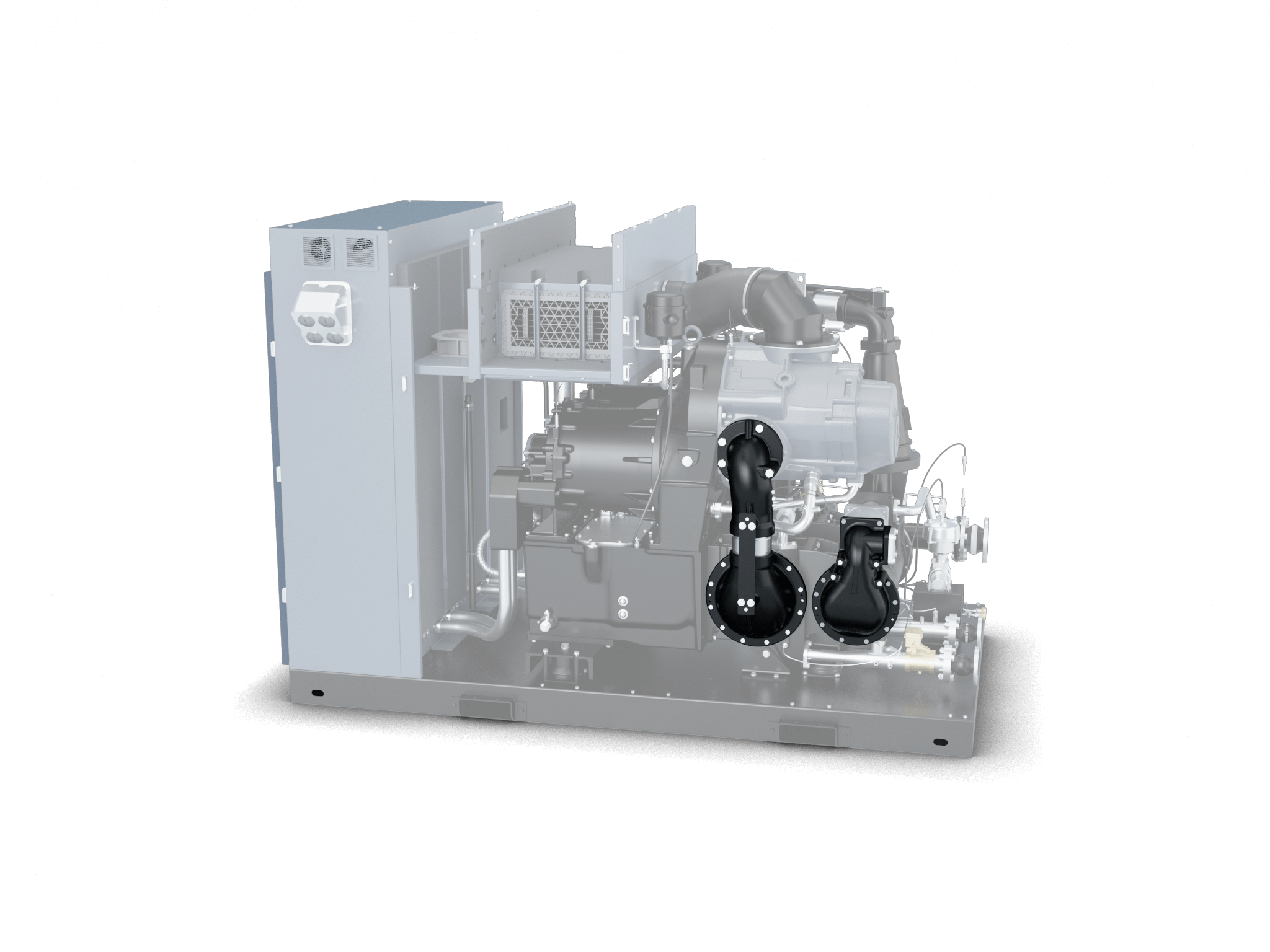

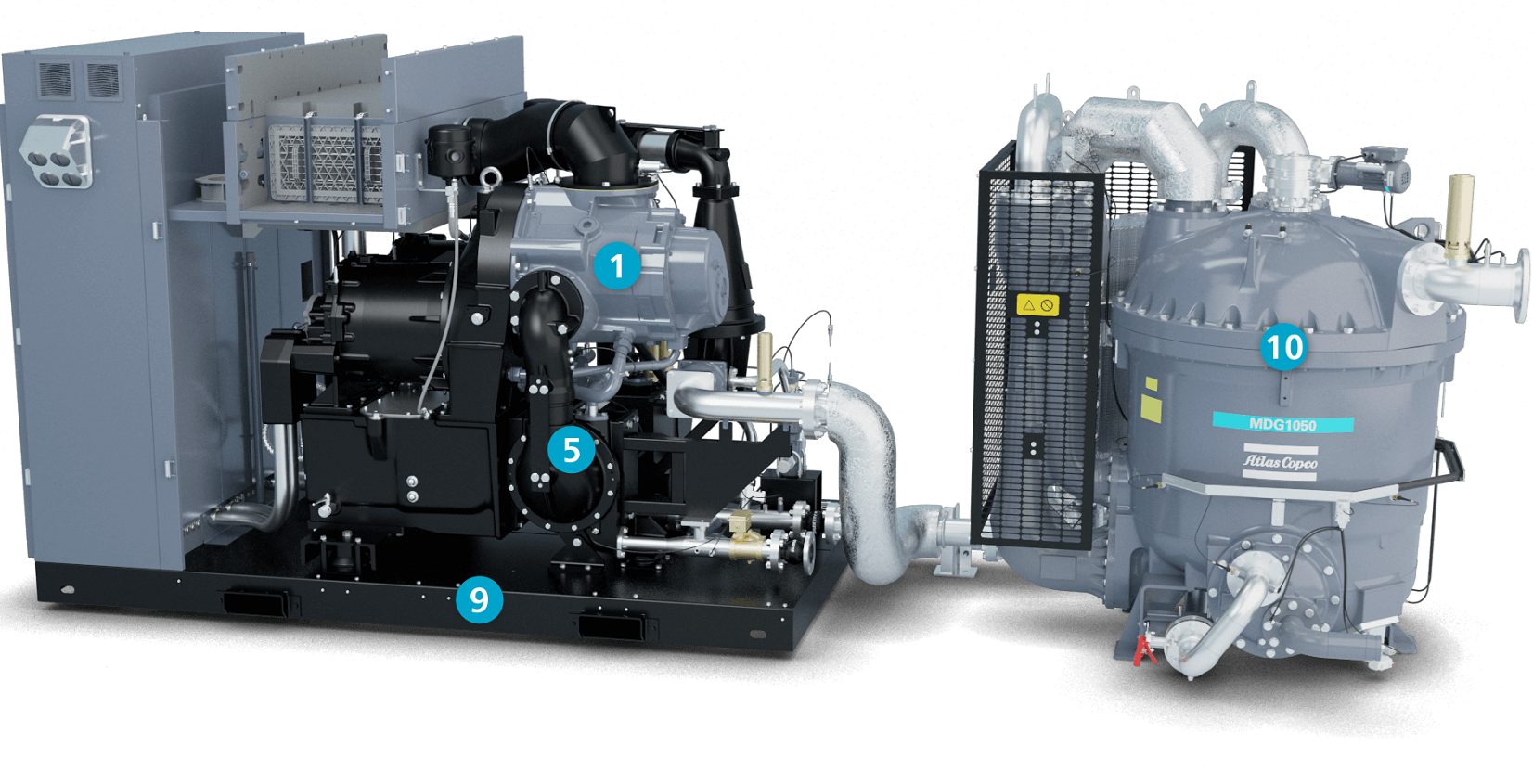

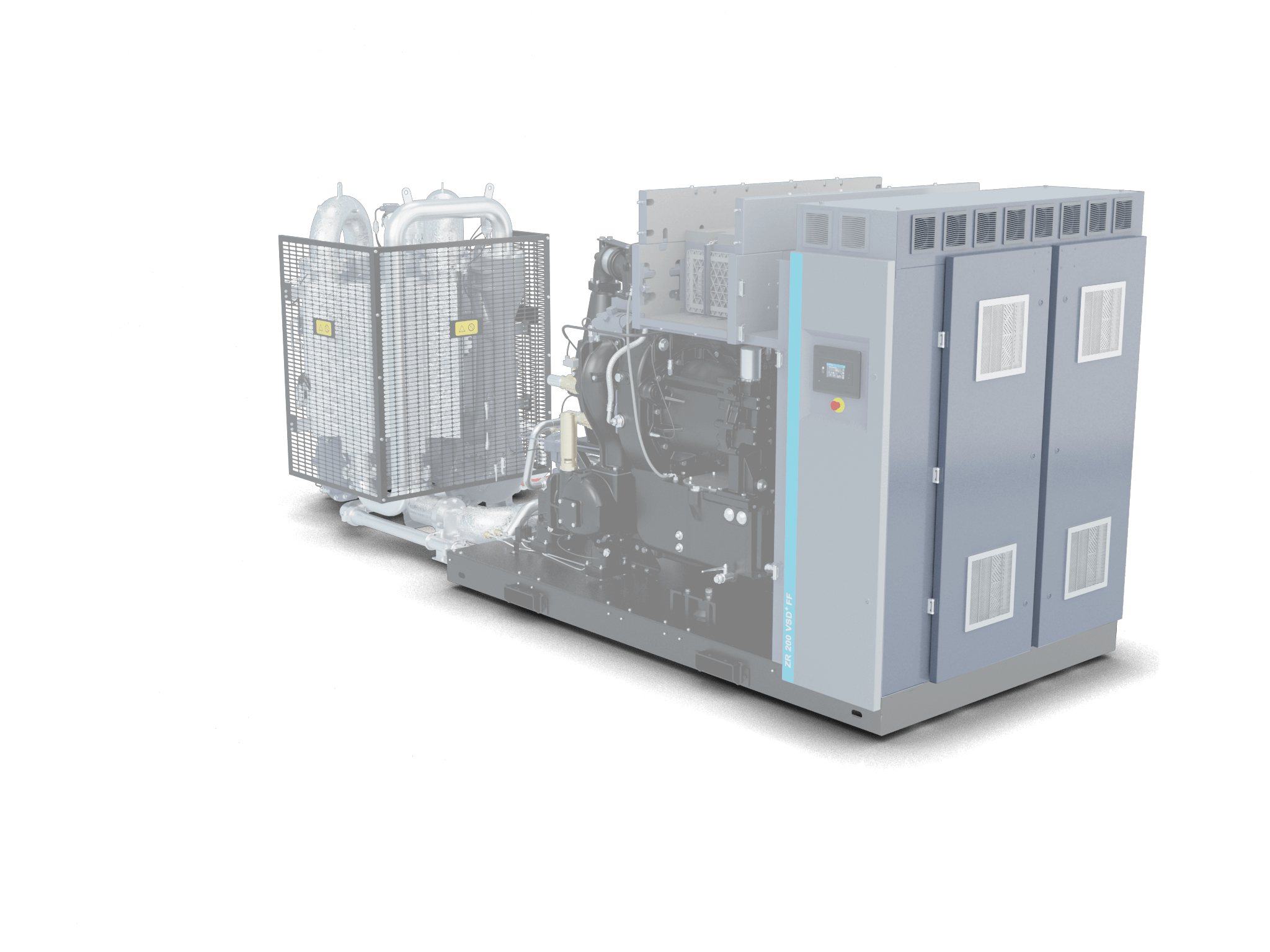

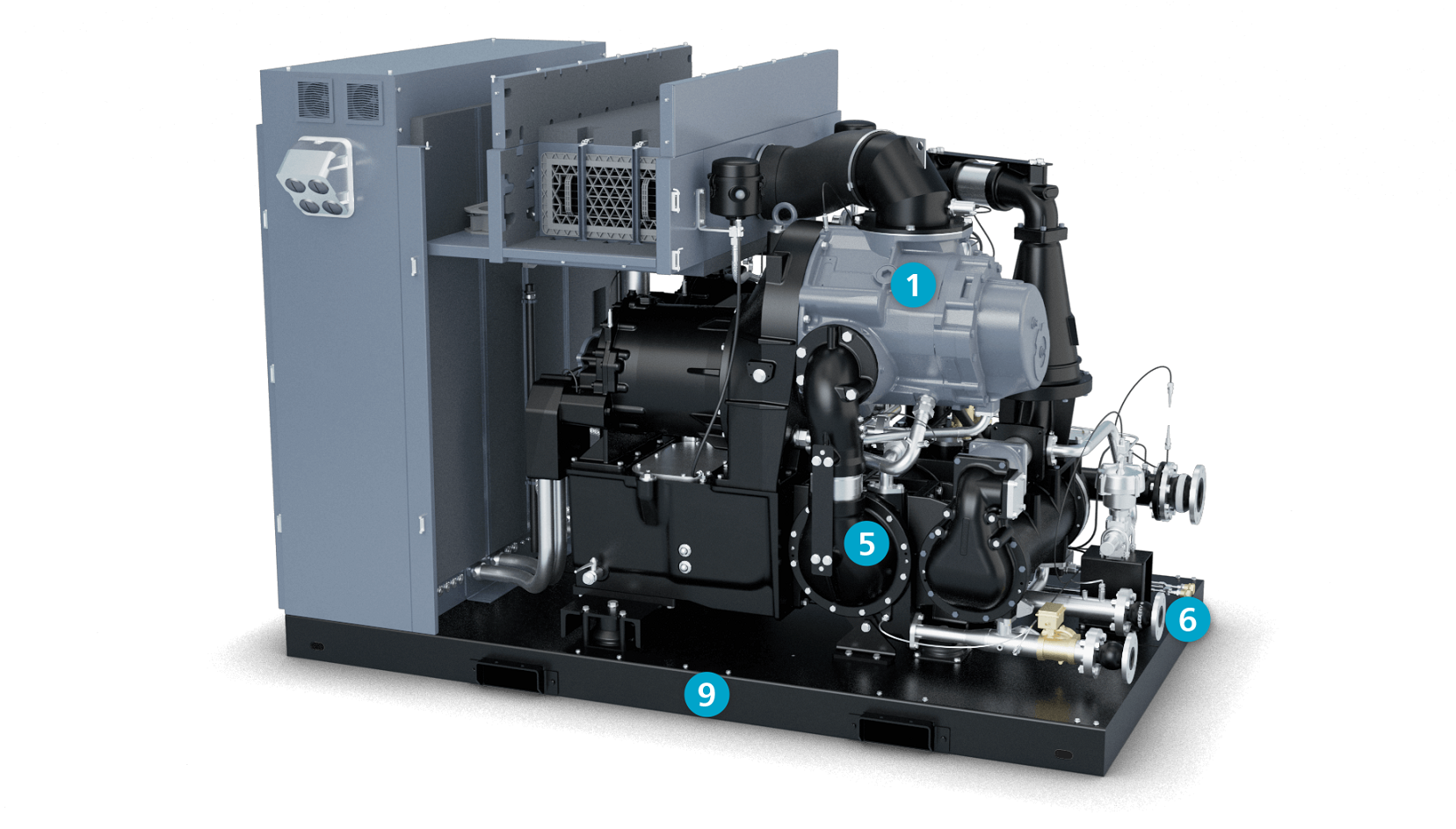

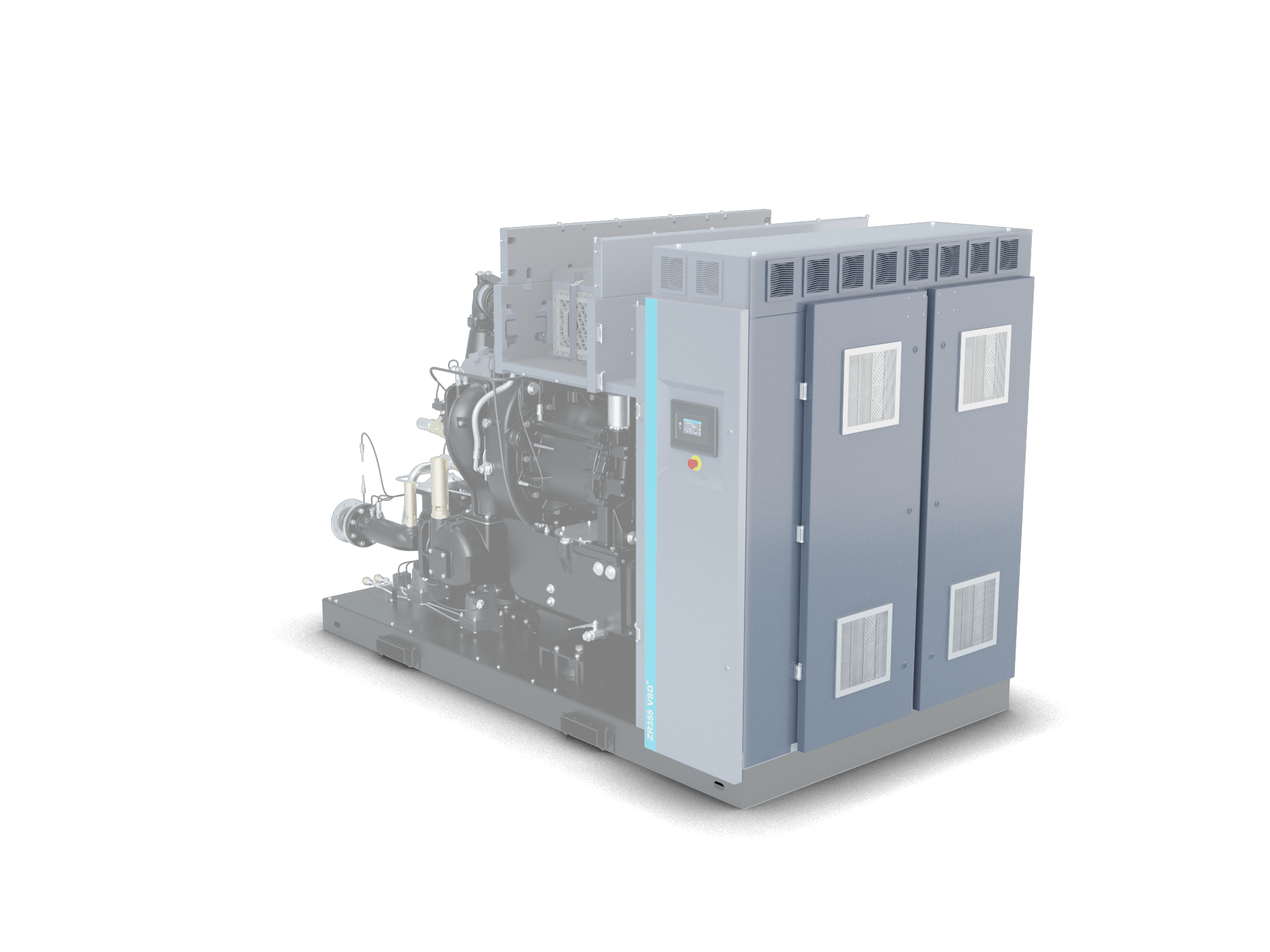

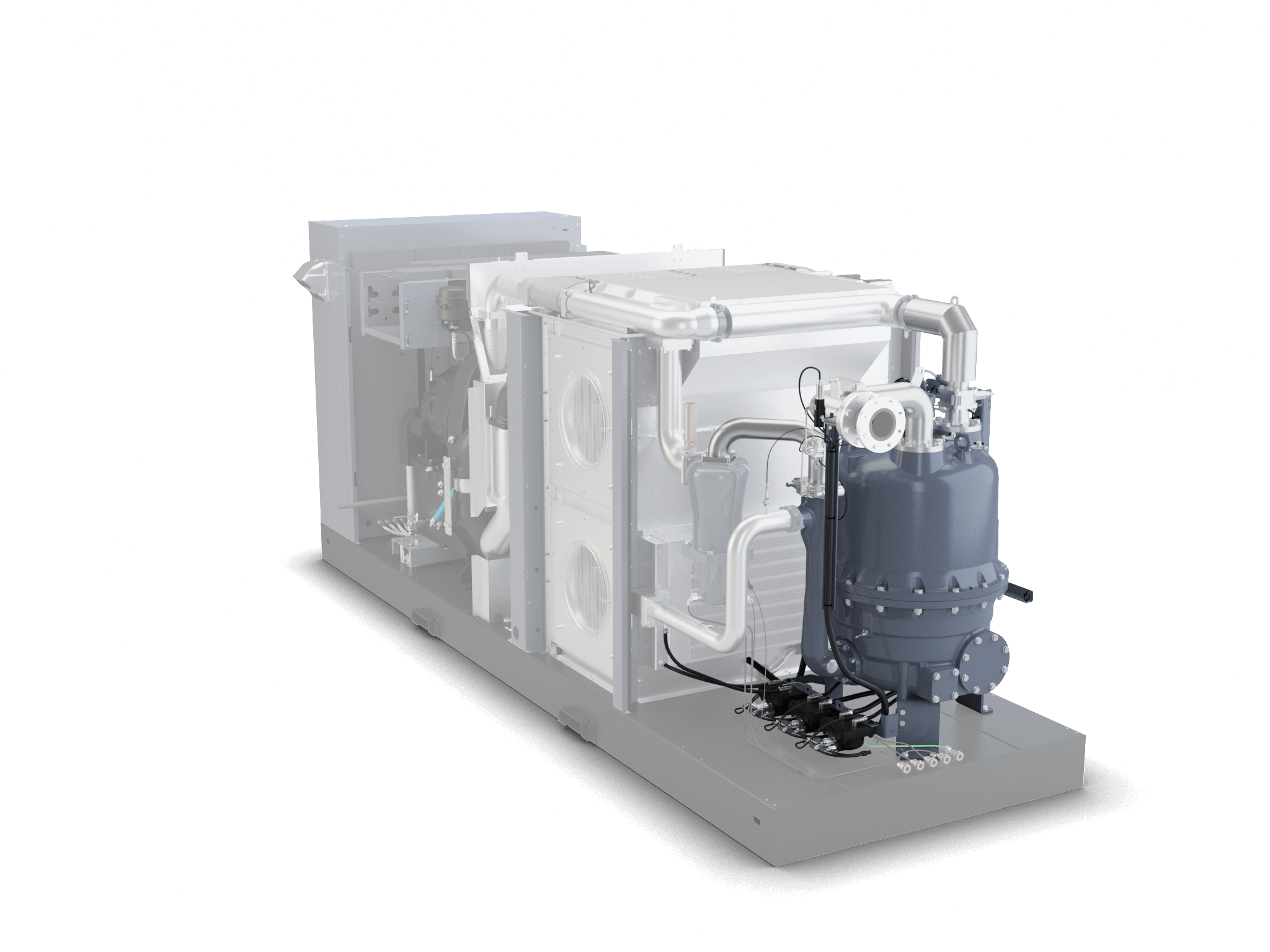

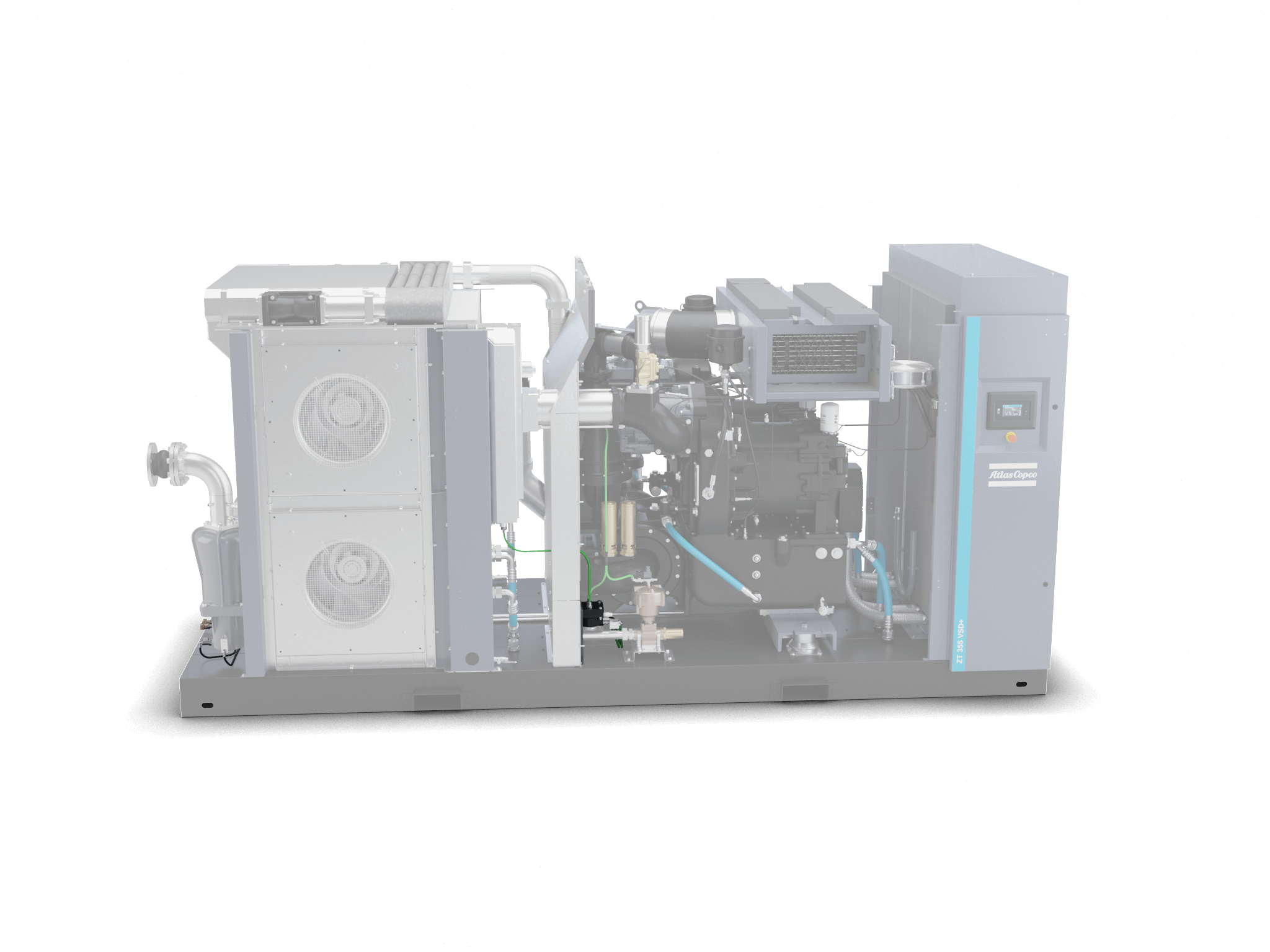

ZR 200-355 VSD⁺ FF (iMDG)

Product

On

Off

Labels

On

Off

Left view

Right view

-

1

High performance elements

-

2

Advanced touch screen monitoring system

-

3

Efficient motor

-

4

NEOS drive

-

5

Reliable cooling

-

6

Zero loss drains

-

7

Easy access

-

8

Soundproof design

-

9

Grouped service items

-

10

Dryer

-

High performance elements

- Next generation world class compression element.

- Atlas Copco superior rotor coating for high durability.

- Thermal efficiency reduces the expansion leading to reduced wear and increased reliability.

- More compact, improved rotor profiles and cooling jackets for maximum durability.

-

Advanced touch screen monitoring system

- User-friendly Elektronikon® Touch, with enhanced connectivity potential.

- Included warning indications, maintenance scheduling and online visualization of the machine’s condition for increased reliability.

-

Efficient motor

- Permanent Magnet water cooled motor with oil lubricated bearings.

- Rock-solid reliability prevents dust and water entering the motor.

-

NEOS drive

- Atlas Copco NEOS inverter is designed to work in the harsh conditions of the compressor house.

- Modular design allows replacement of individual components, reducing maintenance cost.

- The cubicle keeps the inverter cool extending the lifetime & increasing operational efficiency.

-

Reliable cooling

- Cooler with highly efficient water separator for higher reliability.

- Stainless steel enlarged surface coolers to ensure top performance over a long lifetime.

- Pipes with star profile form bi-anodised aluminium for preventing corrosion.

- Easily removable for quick, cost-efficient maintenance.

-

Zero loss drains

- Clearance of all water & contamination.

- Increasing both product & system reliability.

-

Easy access

- Easy access to all components to minimize maintenance times.

- Hinged doors for easy routine maintenance eg. cleaning.

- Saves valuable and often expensive floor space in a facility.

- Highest ratio flow/footprint on the market.

-

Soundproof design

- Silenced canopy ensures optimal working conditions for everyone in the immediate environment.

- Optimized internal ducting and integrated pulsation damper to reduce the noise level.

- High quality coated canopy to prevent dust.

-

Grouped service items

- Minimal service time because service parts are grouped together for ease of access.

- All components are designed for serviceability and long lasting lifetime.

-

Dryer

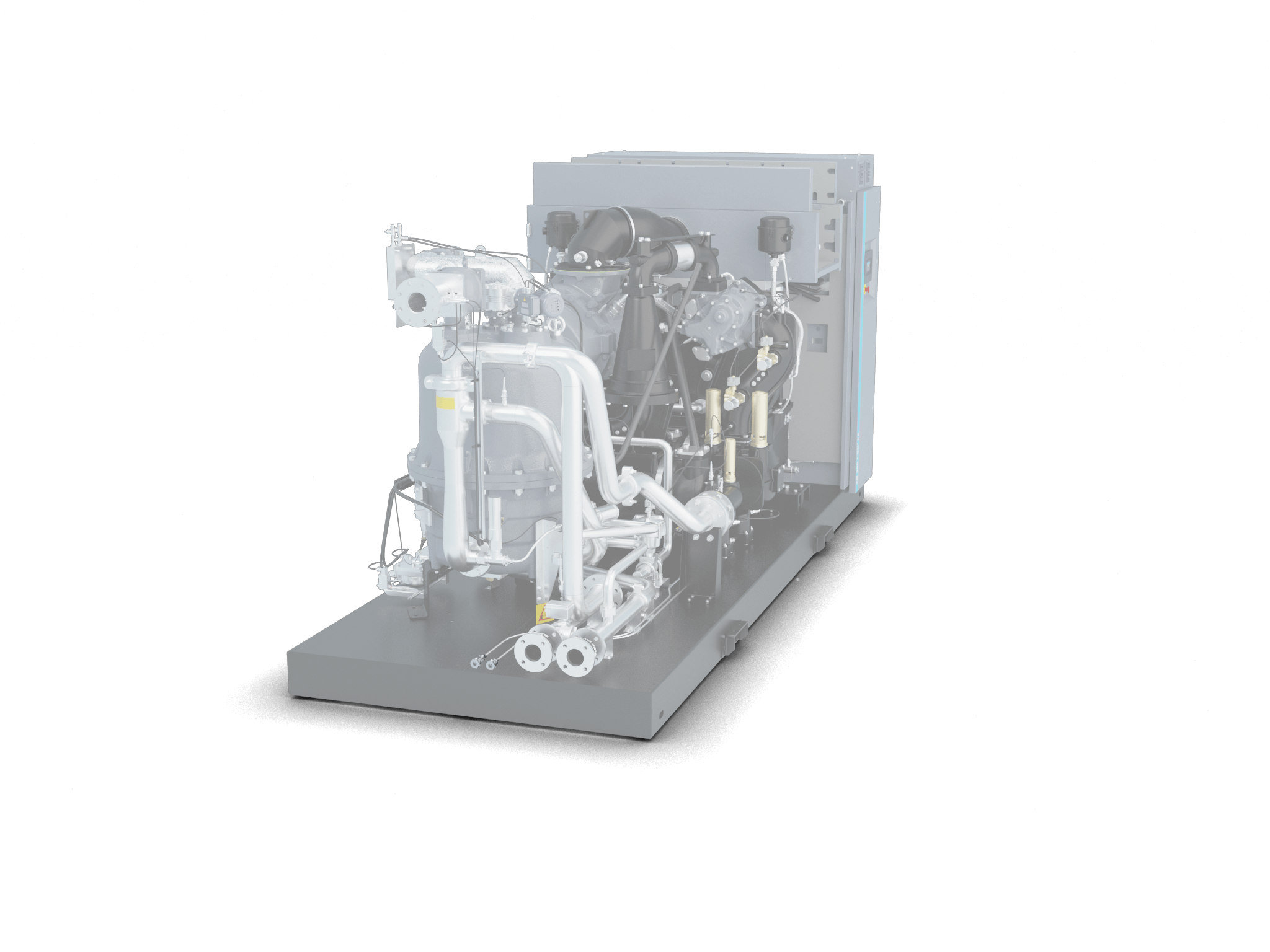

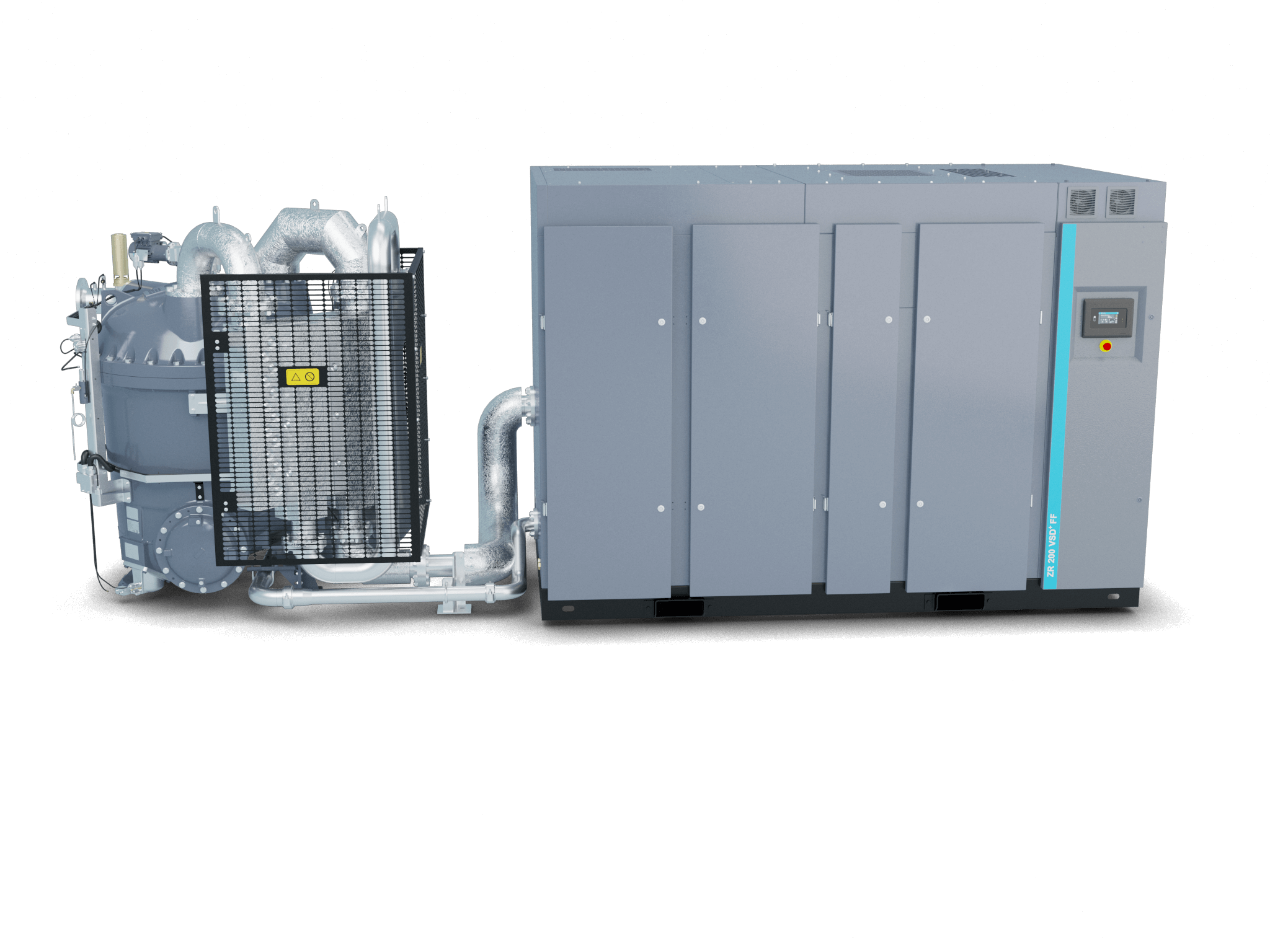

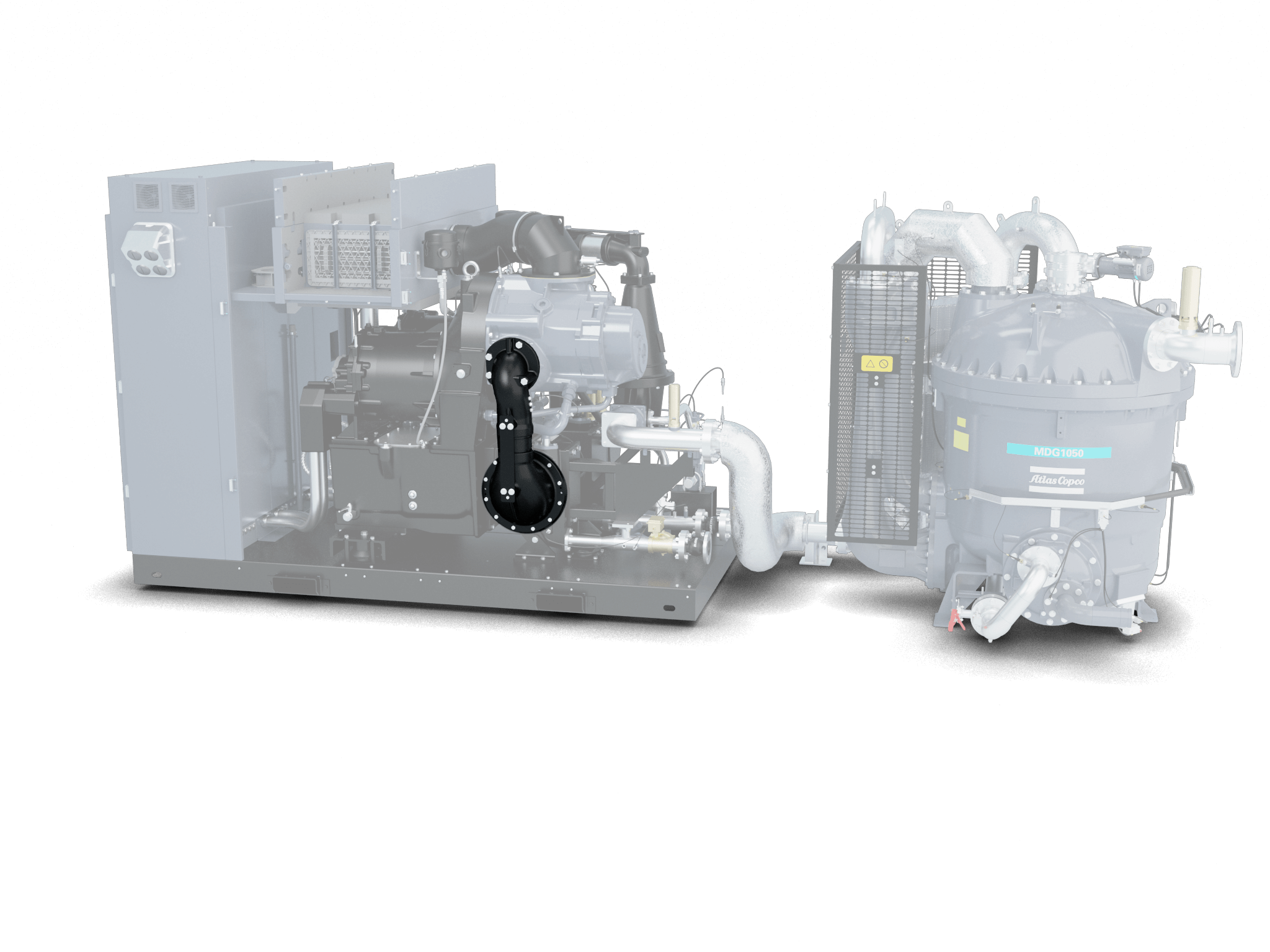

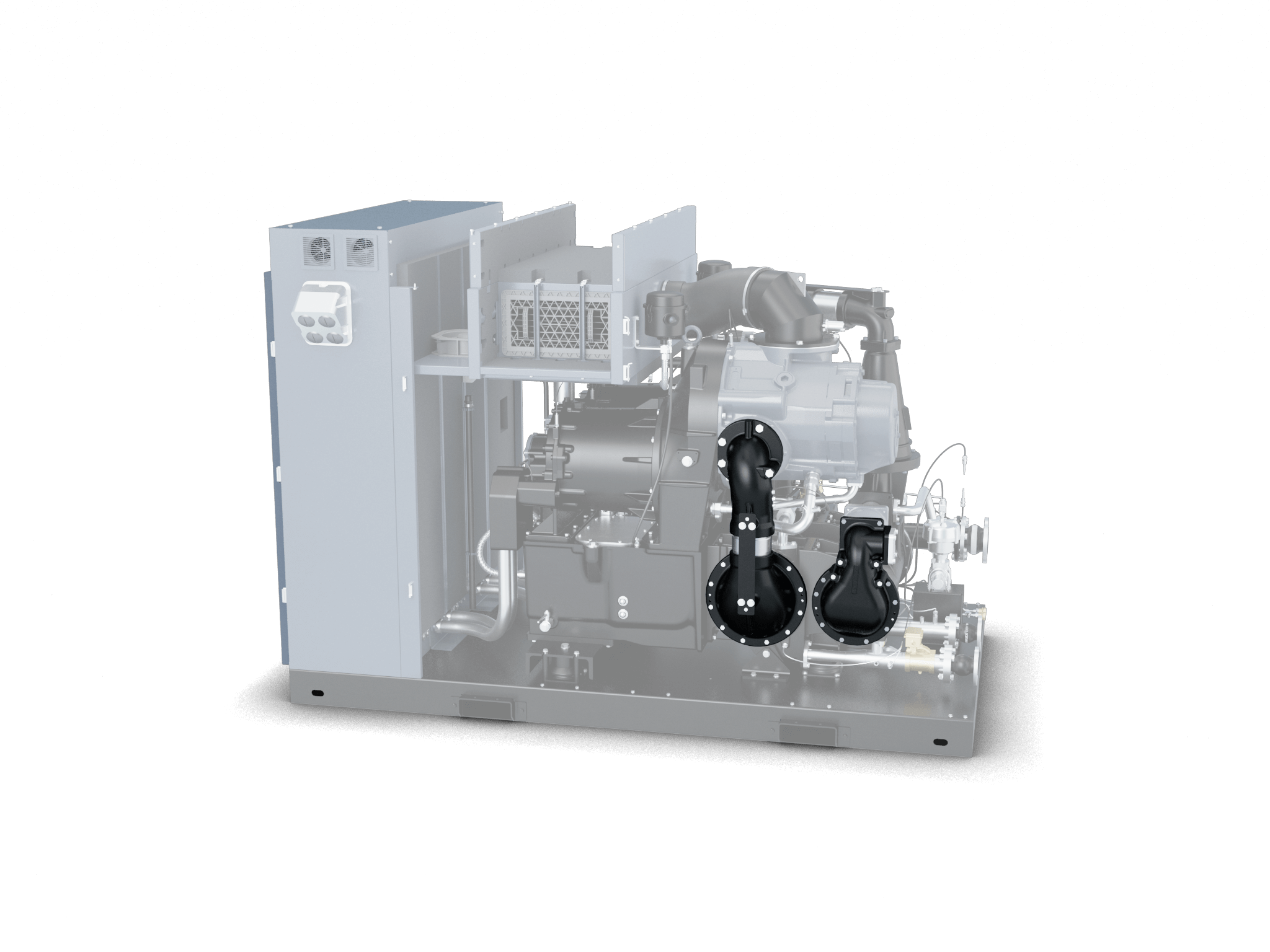

ZR 200-355 VSD⁺ Pack

Product

On

Off

Labels

On

Off

Left view

Right view

-

1

High performance elements

-

2

Advanced touch screen monitoring system

-

3

Efficient motor

-

4

NEOS drive

-

5

Reliable cooling

-

6

Zero loss drains

-

7

Easy access

-

8

Soundproof design

-

9

Grouped service items

-

High performance elements

- Next generation world class compression element.

- Atlas Copco superior rotor coating for high durability.

- Thermal efficiency reduces the expansion leading to reduced wear and increased reliability.

- More compact, improved rotor profiles and cooling jackets for maximum durability.

-

Advanced touch screen monitoring system

- User-friendly Elektronikon® Touch, with enhanced connectivity potential.

- Included warning indications, maintenance scheduling and online visualization of the machine’s condition for increased reliability.

-

Efficient motor

- Permanent Magnet water cooled motor with oil lubricated bearings.

- Rock-solid reliability prevents dust and water entering the motor.

-

NEOS drive

- Atlas Copco NEOS inverter is designed to work in the harsh conditions of the compressor house.

- Modular design allows replacement of individual components, reducing maintenance cost.

- The cubicle keeps the inverter cool extending the lifetime & increasing operational efficiency.

-

Reliable cooling

- Cooler with highly efficient water separator for higher reliability

- Stainless steel enlarged surface coolers to ensure top performance over a long lifetime

- Pipes with star profile form bi-anodised aluminium for preventing corrosion

- Easily removable for quick, cost-efficient maintenance

-

Zero loss drains

- Clearance of all water & contamination

- Increasing both product & system reliability

-

Easy access

- Easy access to all components to minimize maintenance times

- Hinged doors for easy routine maintenance e.g. cleaning

- Saves valuable and often expensive floor space in a facility

- Highest ratio flow/footprint on the market

-

Soundproof design

- Silenced canopy ensures optimal working conditions for everyone in the immediate environment

- Optimized internal ducting and integrated pulsation damper to reduce the noise level

- High quality coated canopy to prevent dust

-

Grouped service items

- Minimal service time because service parts are grouped together for ease of access.

- All components are designed for serviceability and long lasting lifetime.

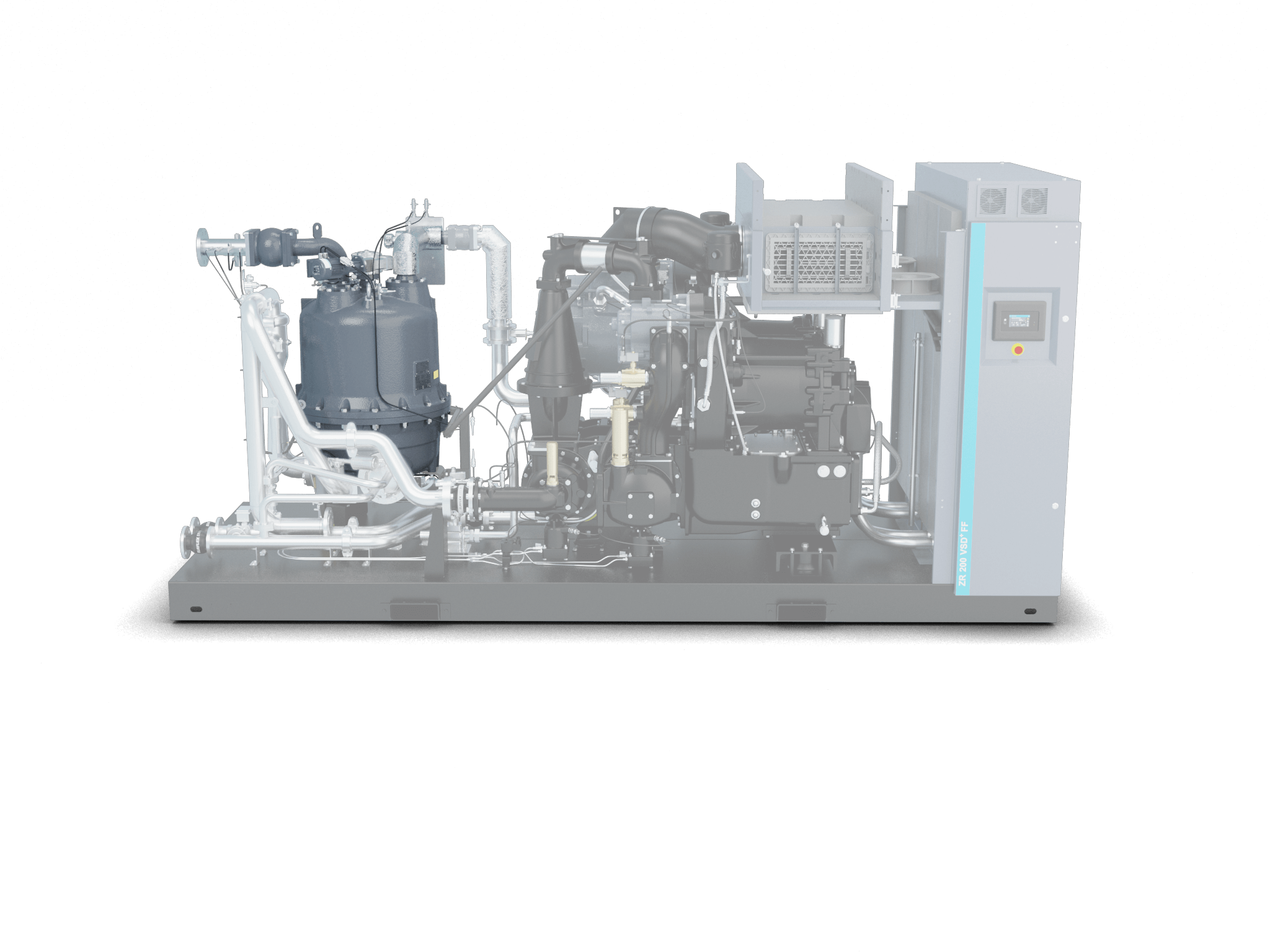

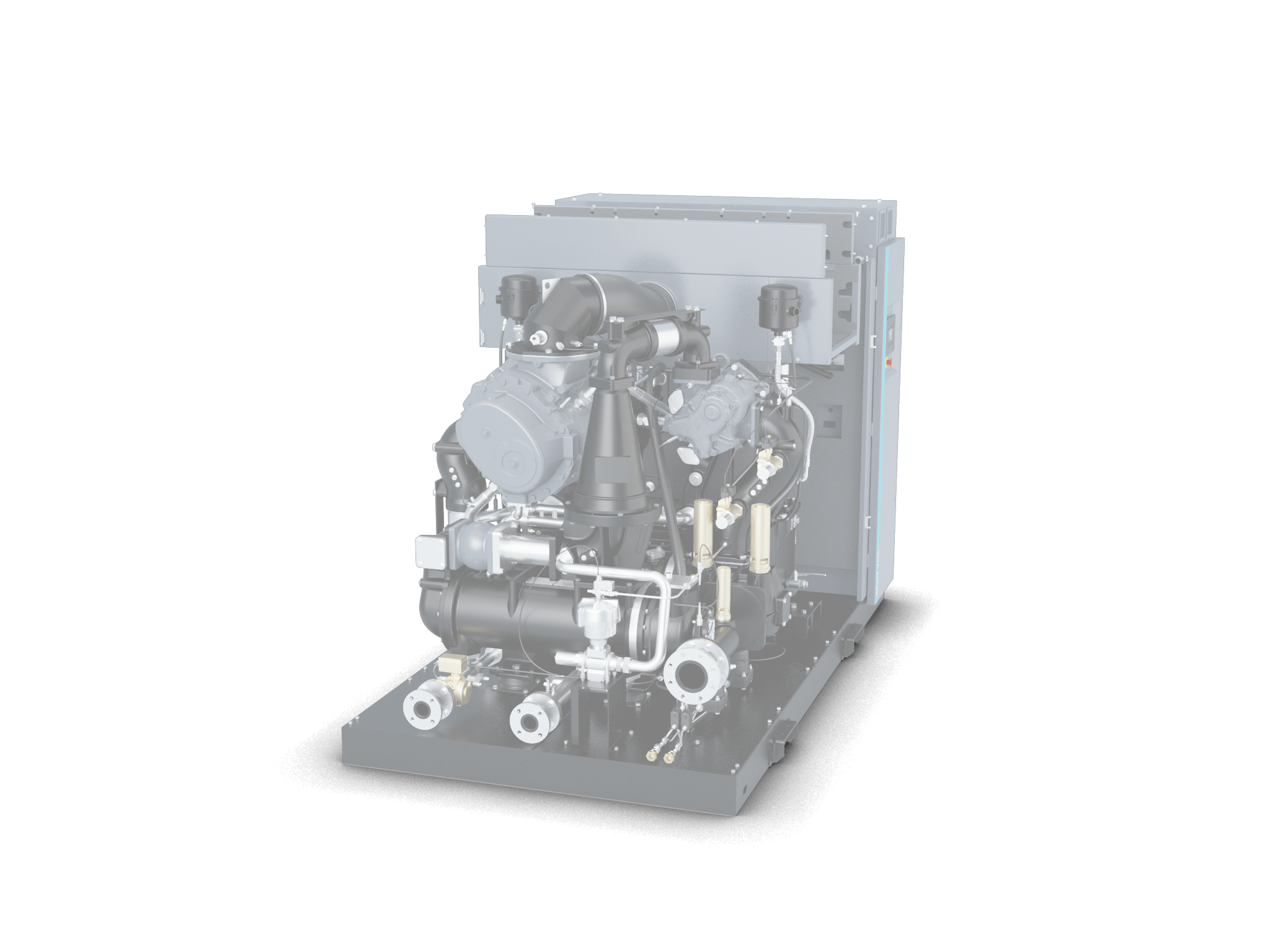

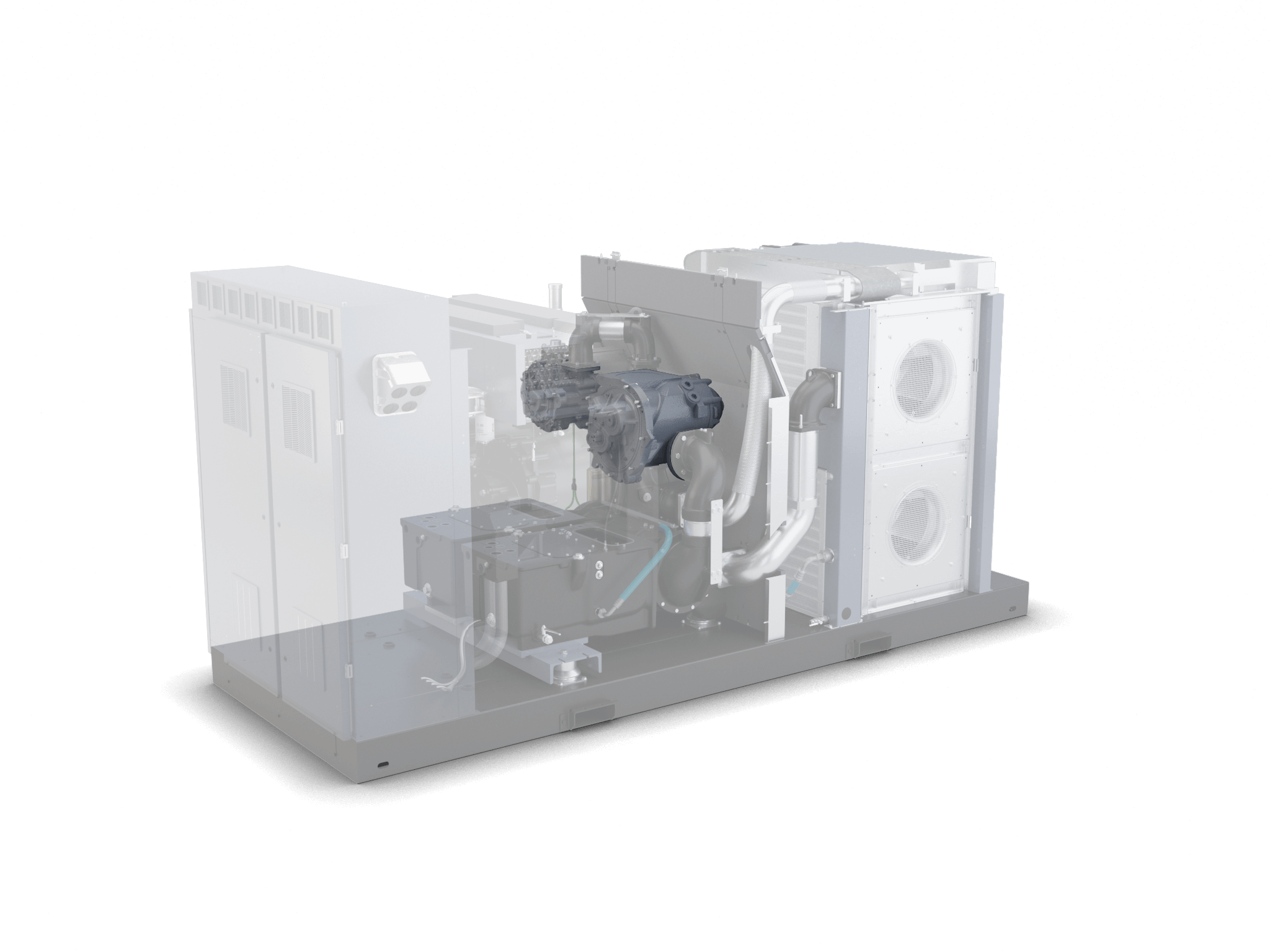

ZT 200-355 VSD⁺ FF (iMD)

Product

On

Off

Labels

On

Off

Left view

Right view

-

1

High performance elements

-

2

Advanced touch screen monitoring system

-

3

Efficient motor

-

4

NEOS drive

-

5

Reliable cooling

-

6

Zero loss drains

-

7

Easy access

-

8

Soundproof design

-

9

Grouped service items

-

10

Integrated dryer

-

High performance elements

- Next generation world class compression element

- Atlas Copco superior rotor coating for high durability

- Thermal efficiency reduces the expansion leading to reduced

wear and increased reliability - More compact, improved rotor profiles and cooling jackets for

maximum durability

-

Advanced touch screen monitoring system

- User-friendly Elektronikon® Touch, with enhanced connectivity

potential - Included warning indications, maintenance scheduling and

online visualization of the machine’s condition for increased

reliability

- User-friendly Elektronikon® Touch, with enhanced connectivity

-

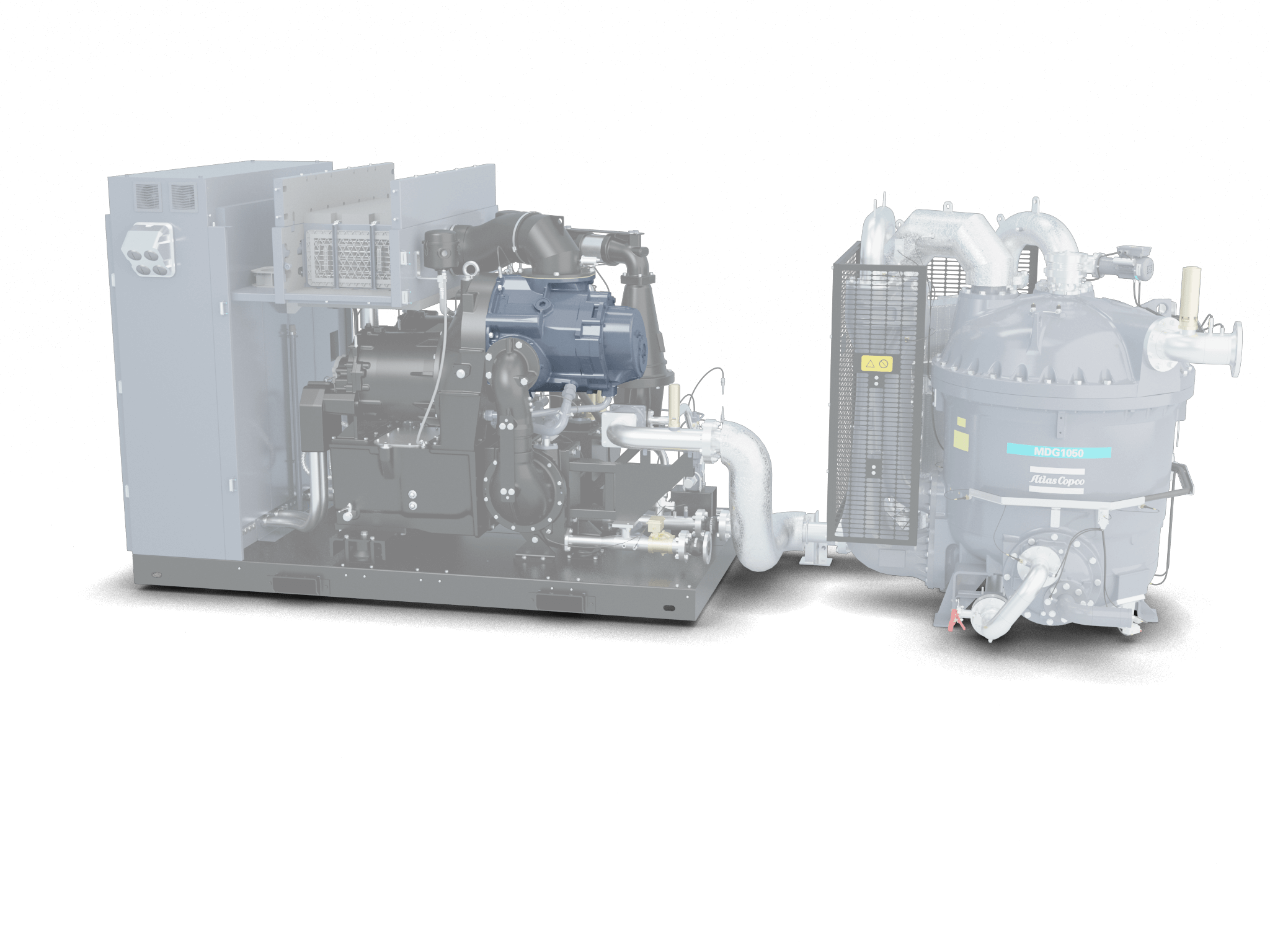

Efficient motor

- Permanent Magnet oil-cooled motor with oil lubricated

bearings - Rock-solid reliability prevents dust and water entering the

motor.

- Permanent Magnet oil-cooled motor with oil lubricated

-

NEOS drive

- Atlas Copco NEOS inverter is designed to work in the harsh

conditions of the compressor house - Modular design allows replacement of individual components,

reducing maintenance cost - The cubicle keeps the inverter cool extending the lifetime &

increasing operational efficiency

- Atlas Copco NEOS inverter is designed to work in the harsh

-

Reliable cooling

- Coolers with highly efficient water separator for higher reliability

- Stainless steel precooler to protect aftercooler from heat loads

- Stress-free connections

- Compact integrated design resulting in low pressure drop

- High efficiency radial fans and Aluminium brazed heat exchanger lead to low cooler approach temperatures

-

Zero loss drains

- Clearance of all water & contamination

- Increasing both product & system reliability

-

Easy access

- Easy access to all components to minimize maintenance times

- Hinged doors for easy routine maintenance eg. cleaning

- Saves valuable and often expensive floor space in a facility

- Highest ratio flow/footprint on the market

-

Soundproof design

- Silenced canopy ensures optimal working conditions for

everyone in the immediate environment - Optimized internal ducting and integrated pulsation damper to

reduce the noise level - High quality coated canopy to prevent dust

- Silenced canopy ensures optimal working conditions for

-

Grouped service items

- Minimal service time because service parts are grouped

together for ease of access - All components are designed for serviceability and long lasting

lifetime

- Minimal service time because service parts are grouped

-

Integrated dryer

- Having an integrated dryer helps for easier installation, less

pressure drop because of more efficient connections - On top of that it also saves a lot of space in your compressor room.

- Having an integrated dryer helps for easier installation, less

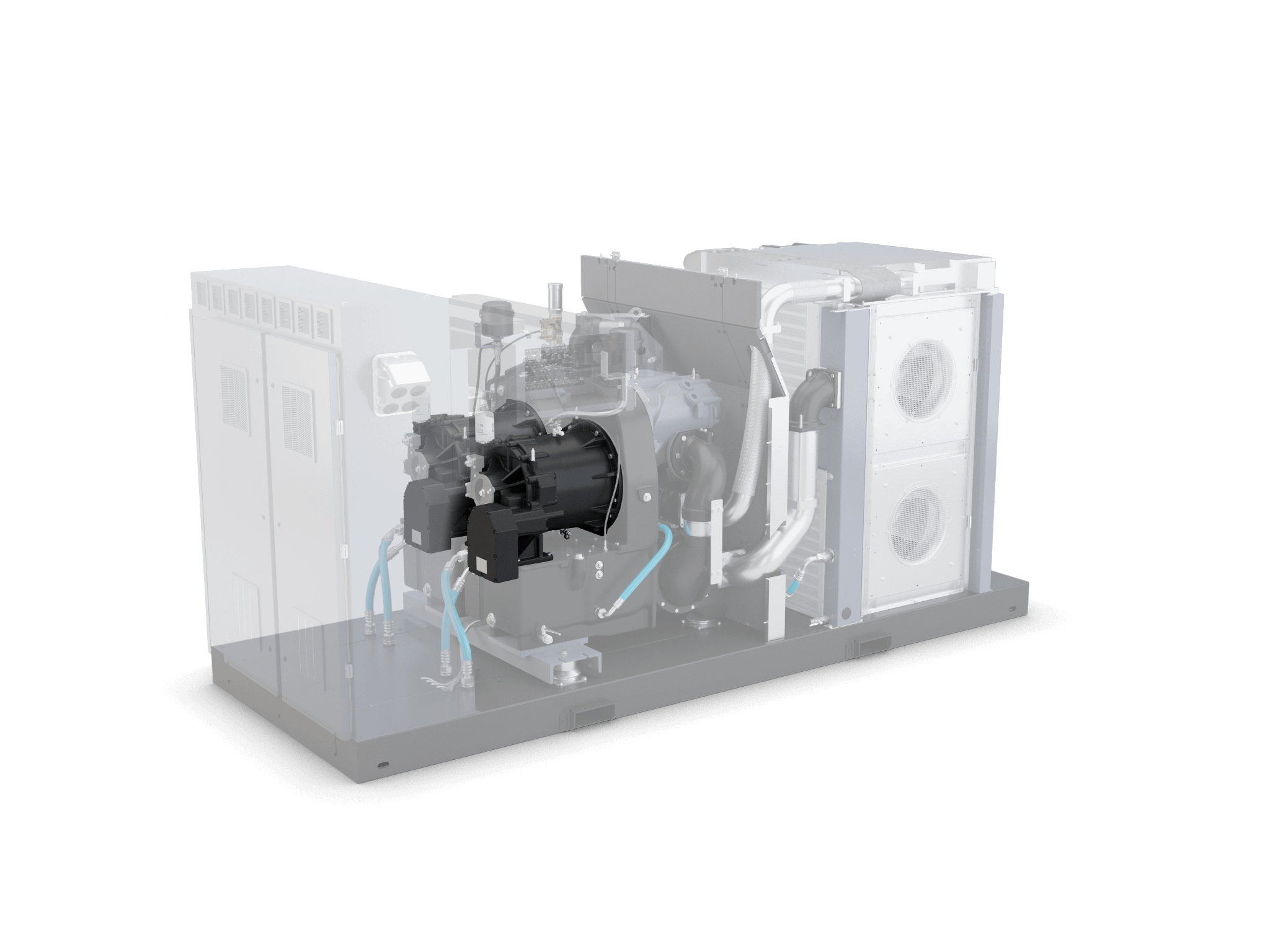

ZT 200-355 VSD⁺ Pack

Product

On

Off

Labels

On

Off

Left view

Right view

-

1

High performance elements

-

2

Advanced touch screen monitoring system

-

3

Efficient motor

-

4

NEOS drive

-

5

Reliable cooling

-

6

Zero loss drains

-

7

Easy access

-

8

Soundproof design

-

9

Grouped service items

-

High performance elements

- Next generation world class compression element

- Atlas Copco superior rotor coating for high durability

- Thermal efficiency reduces the expansion leading to reduced

wear and increased reliability - More compact, improved rotor profiles and cooling jackets for

maximum durability

-

Advanced touch screen monitoring system

- User-friendly Elektronikon® Touch, with enhanced connectivity

potential - Included warning indications, maintenance scheduling and

online visualization of the machine’s condition for increased

reliability

- User-friendly Elektronikon® Touch, with enhanced connectivity

-

Efficient motor

- Permanent Magnet oil-cooled motor with oil lubricated

bearings - Rock-solid reliability prevents dust and water entering the

motor

- Permanent Magnet oil-cooled motor with oil lubricated

-

NEOS drive

- Atlas Copco NEOS inverter is designed to work in the harsh

conditions of the compressor house - Modular design allows replacement of individual components,

reducing maintenance cost - The cubicle keeps the inverter cool extending the lifetime &

increasing operational efficiency

- Atlas Copco NEOS inverter is designed to work in the harsh

-

Reliable cooling

- Coolers with highly efficient water separator for higher reliability

- Stainless steel precooler to protect aftercooler from heat loads

- Stress-free connections

- Compact integrated design resulting in low pressure drop

- High efficiency radial fans and Aluminium brazed heat exchanger lead to low cooler approach temperatures

-

Zero loss drains

- Clearance of all water & contamination

- Increasing both product & system reliability

-

Easy access

- Easy access to all components to minimize maintenance times

- Hinged doors for easy routine maintenance eg. cleaning

- Saves valuable and often expensive floor space in a facility

- Highest ratio flow/footprint on the market

-

Soundproof design

- Silenced canopy ensures optimal working conditions for

everyone in the immediate environment - Optimized internal ducting and integrated pulsation damper to

reduce the noise level - High quality coated canopy to prevent dust

- Silenced canopy ensures optimal working conditions for

-

Grouped service items

- Minimal service time because service parts are grouped

together for ease of access - All components are designed for serviceability and long lasting

lifetime

- Minimal service time because service parts are grouped