ZT 75-160 VSD⁺

ZT 75-160 VSD⁺

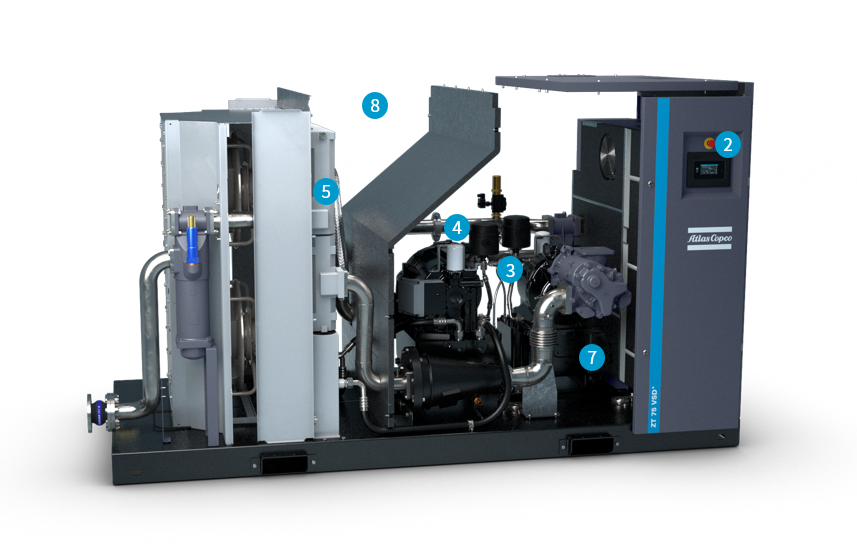

ZT 75 VSD+

-

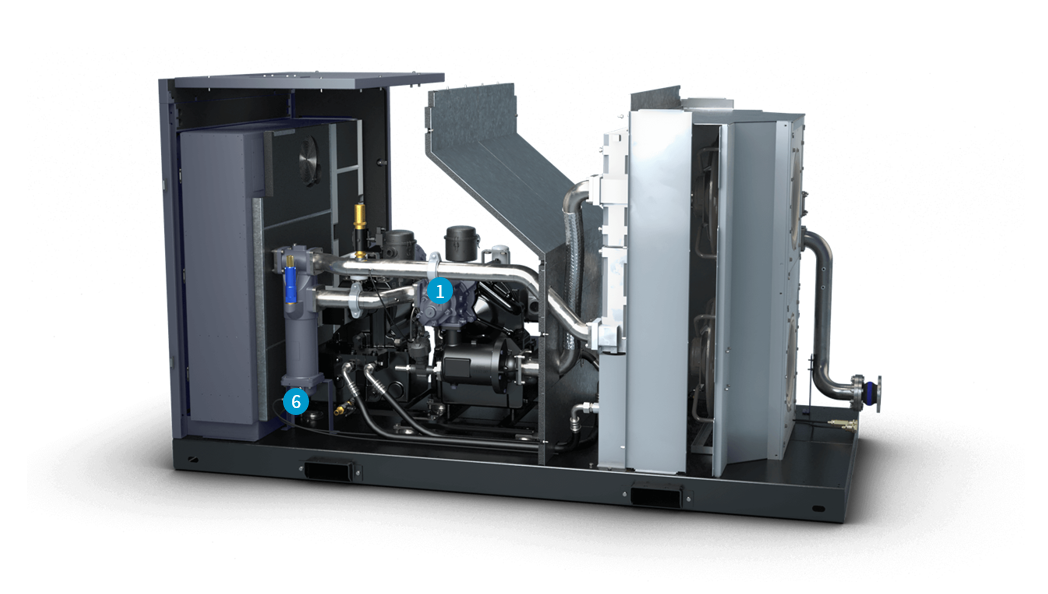

1

Reliable element

-

2

Advanced touch screen monitoring system

-

3

Highly reliable motor

-

4

Easy access

-

5

Reliable cooling

-

6

Zero loss drains

-

7

Grouped service items

-

8

Soundproof design

-

9

Reliable control – NEOS drive

-

10

Integrated dryer

-

Reliable element

• Next generation world class compression element.

• Atlas Copco superior rotor coating for high durability.

• Thermal efficiency reduces the expansion leading to reduces wear and increased reliability.

• More compact, improved rotor profiles and cooling jackets for maximum durability.

-

Advanced touch screen monitoring system

• User-friendly Elektronikon® Touch, with enhanced connectivity potential.

• Included warning indications, maintenance scheduling and online visualization of the machine’s condition for increased reliabiltiy.

-

Highly reliable motor

• IP66 Permanent Magnet water cooled motor with oil lubricated bearings.

• Rock-solid reliability prevents dust and water entering the motor.

-

Easy access

• Easy access to all components to minimize maintenance times.

• Hinged doors for easy routine maintenance e.g. cleaning.

• Saves valuable and often expensive floor space in a facility.

• Highest ratio flow/footprint on the market.

-

Reliable cooling

- Stress-free connections

- Compact integrated design resulting in low pressure drop

- High efficiency radial fans and Aluminium brazed heat exchanger lead to low cooler approach temperatures

-

Zero loss drains

• Clearance of all water & contamination

• Increasing both product & system reliability.

-

Grouped service items

• Minimal service time because service parts are grouped together for ease of access.

• All components are designed for serviceability and long lasting lifetime.

-

Soundproof design

• Silenced canopy ensures optimal working conditions for everyone in the immediate environment.

• Optimized internal ducting and integrated pulsation damper to reduce the noise level.

• High quality coated canopy to prevent rust.

-

Reliable control – NEOS drive

• Atlas Copco NEOS inverter designed to work in the harsh conditions of the compressor house.

• Modular design allows replacement of individual components, reducing maintenance cost.

• Cubicle designed to keep the inverter cool extending the lifetime & increase operational efficiency.

-

Integrated dryer

Having an integrated dryer helps for easier installation, less pressure drop because of more efficient connections. On top of that it also saves a lot of space in your compressor room.

ZR 75-160 VSD⁺ iMDG

ZR 75-160 VSD⁺ iMDG

ZR 75-160 VSD+ iMDG

-

1

High performance elements

-

2

Advanced touch screen monitoring system

-

3

Efficient motor

-

4

NEOS drive

-

5

Reliable cooling

-

6

Zero loss drains

-

7

Easy access

-

8

Soundproof design

-

9

Grouped service items

-

10

Integrated dryer

-

High performance elements

- Next generation world class compression element.

- Atlas Copco superior rotor coating for high durability.

- Thermal efficiency reduces the expansion leading to reduced wear and increased reliability.

- More compact, improved rotor profiles and cooling jackets for maximum durability.

-

Advanced touch screen monitoring system

- User-friendly Elektronikon® Touch, with enhanced connectivity potential.

- Included warning indications, maintenance scheduling and online visualization of the machine’s condition for increased reliability.

-

Efficient motor

- Permanent Magnet water cooled motor with oil lubricated bearings.

- Rock-solid reliability prevents dust and water entering the motor.

-

NEOS drive

- Atlas Copco NEOS inverter is designed to work in the harsh conditions of the compressor house.

- Modular design allows replacement of individual components, reducing maintenance cost.

- The cubicle keeps the inverter cool extending the lifetime & increasing operational efficiency.

-

Reliable cooling

- Cooler with highly efficient water separator for higher reliability.

- Stainless steel enlarged surface coolers to ensure top performance over a long lifetime.

- Pipes with star profile form bi-anodised aluminium for preventing corrosion

- Easily removable for quick, cost-efficient maintenance.

-

Zero loss drains

- Clearance of all water & contamination.

- Increasing both product & system reliability.

-

Easy access

- Easy access to all components to minimize maintenance times.

- Hinged doors for easy routine maintenance eg. cleaning.

- Saves valuable and often expensive floor space in a facility.

- Highest ratio flow/footprint on the market.

-

Soundproof design

- Silenced canopy ensures optimal working conditions for everyone in the immediate environment.

- Optimized internal ducting and integrated pulsation damper to reduce the noise level.

- High quality coated canopy to prevent dust.

-

Grouped service items

- Minimal service time because service parts are grouped together for ease of access.

- All components are designed for serviceability and long lasting lifetime.

-

Integrated dryer

- Having an integrated dryer helps for easier installation, less pressure drop because of more efficient connections

- On top of that it also saves a lot of space in your compressor room.