To ensure the success of your business, you need to guarantee consistent quality while minimizing your overheads. A ZR/ZT 30-55 FLX compressor keeps you on track by delivering a reliable supply of clean, dry air. Every component is optimized for long life and easy servicing.

Engineered to enhance your profits

ZT 30-55 FLX FF (iD)

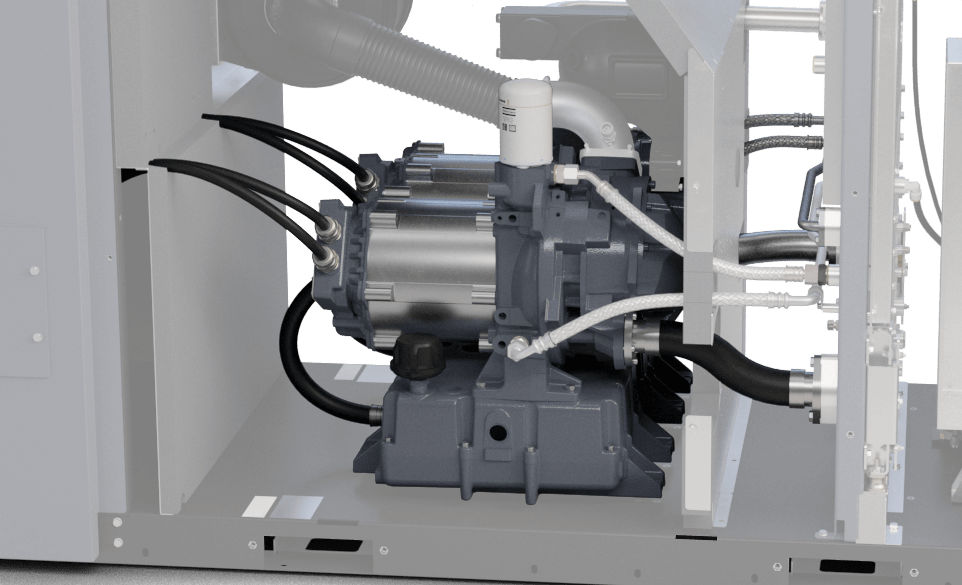

ZT 30-55 FLX FF Front Interior Element Highlights

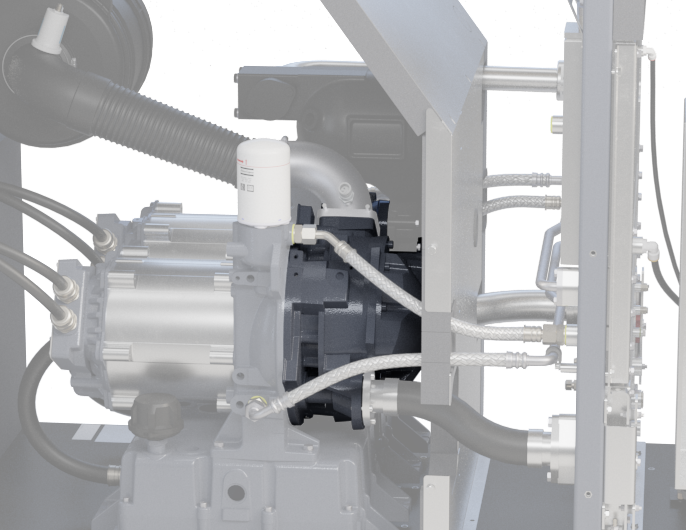

ZT 30-55 FLX FF Back Interior Element Highlights

-

1

Advanced Elektronikon® monitoring system

-

2

Compact design

-

3

NEOS Next frequency converters

-

4

Soundproof canopy

-

5

Permanent Magnet Motors

-

6

Oil-free tooth element

-

7

Reliable cooling

-

8

Low maintenance

-

9

Integrated dryer

-

Advanced Elektronikon® monitoring system

– User-friendly Elektronikon® Touch, with enhanced connectivity potential.

– Included warning indications, maintenance scheduling and online visualization of the machine’s condition for increased reliability.

-

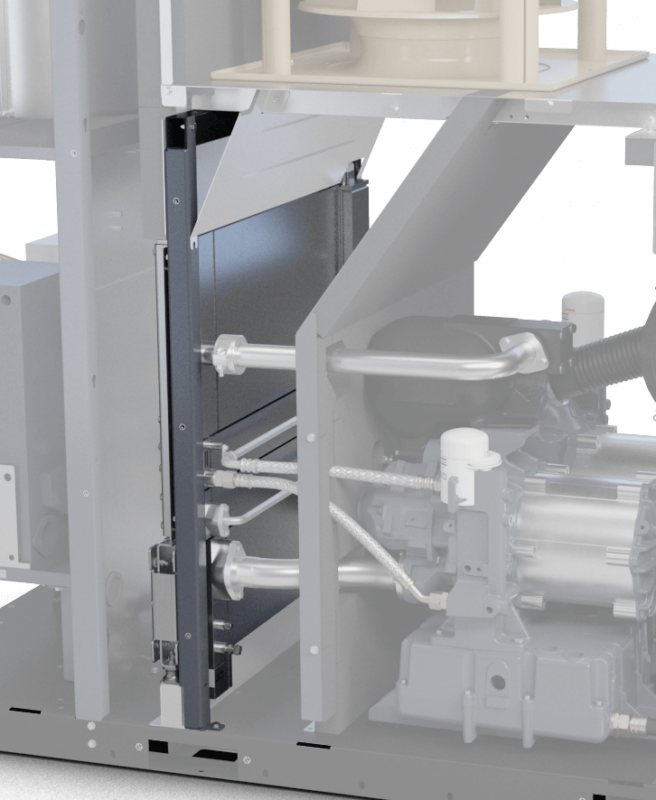

Compact design

With its compact design, the Full Feature version offers substantial space savings and simplifies installation compared to traditional freestanding dryers.

-

NEOS Next frequency converters

– Our patented NEOS Next designed for IP54 allows the unit to run at minimum speed during unload, reducing the unload power consumption to minimum.

– Designed to withstand temperatures up to 50°C/122°F.

-

Soundproof canopy

– Sound insulation allows for installation in most working environments.

– No need for a separate compressor room.

-

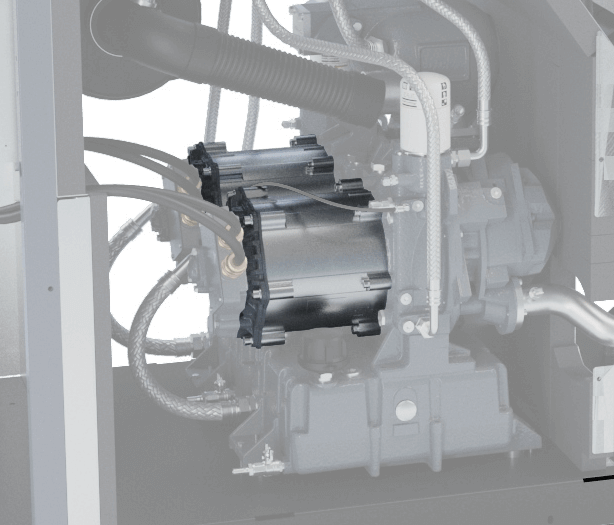

Permanent Magnet Motors

– A proven design with a direct coupled permanent magnet drive motor for low- and high-pressure element, each with their own frequency converter.

– Our oil-cooled permanent magnet motors feature an IP66-rated enclosure which offers a complete protection against dust and powerful water jets to ensure reliable performance even in harsh operating environments.

– Optimized intercooler pressure across the entire speed range ensures stable operation and reinforces long-term reliability, even under demanding conditions.

-

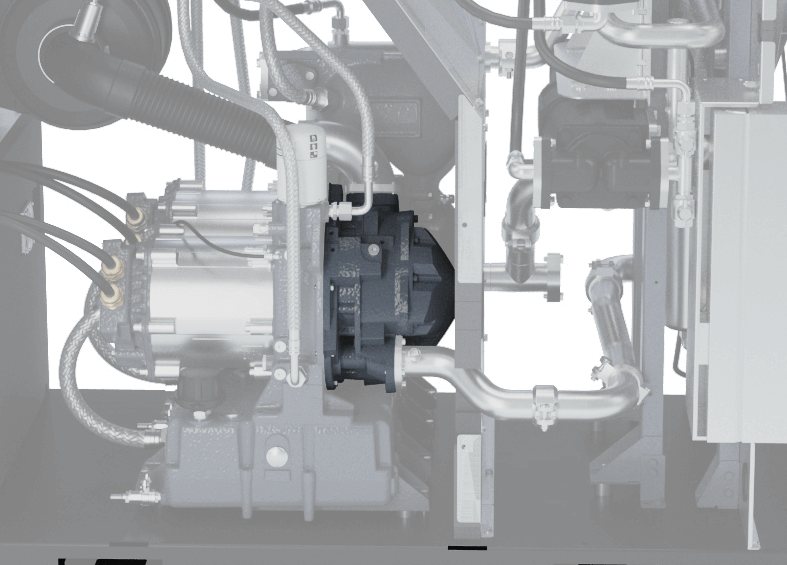

Oil-free tooth element

Our oil-free tooth element is designed for dependable performance. It uses precision gears and durable bearings which reduce wear and keep the machine running smoothly, even under demanding conditions.

-

Reliable cooling

– Available in both air-cooled and water-cooled versions

– Frequency-controlled fan adapts cooling to actual operating conditions, preventing overheating and supporting consistent, reliable operation.

-Oil cooling for permanent magnet motors protects against dust, moisture, and temperature fluctuations, increasing motor lifespan and reducing the risk of failure.

-

Low maintenance

– Strategically placed components allow quick and easy access, simplifying maintenance and reducing downtime.

– Oil-lubricated motor bearings eliminate the need for re-greasing, ensuring long-lasting performance with minimal upkeep.

-

Integrated dryer

– Integrated dryer option reduces installation complexity and minimizes footprint, lowering the risk of setup errors and ensuring consistent performance.

– Available in both Refrigerant and Heat of Compression versions, offering reliable drying performance tailored to different operating needs.

– Heat of Compression version delivers dew point suppression of over 30°C (86°F), ensuring dependable moisture control even in demanding conditions.

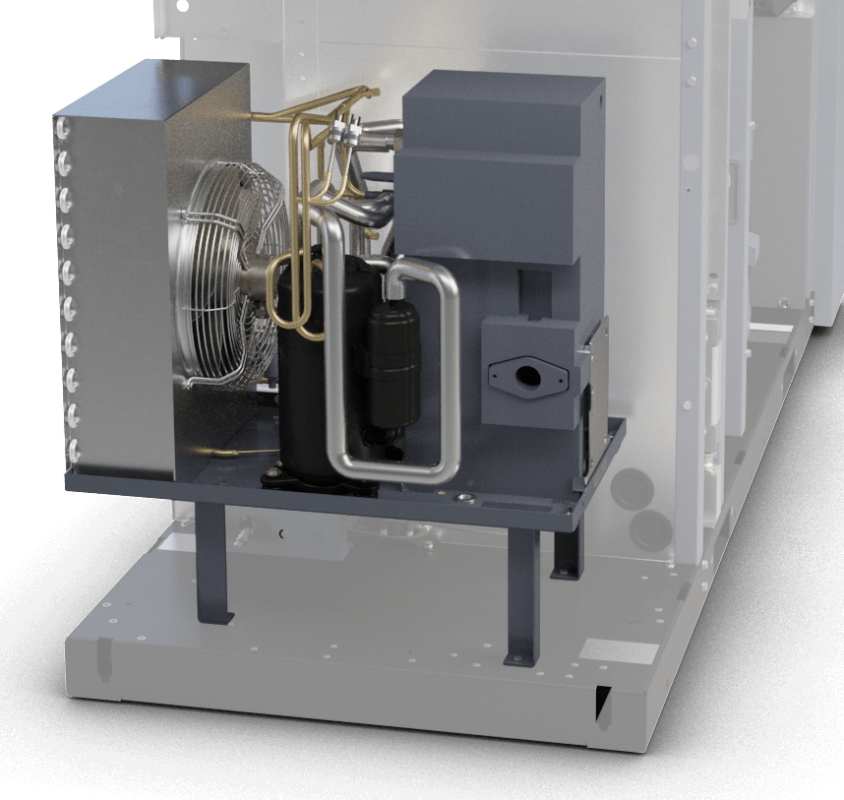

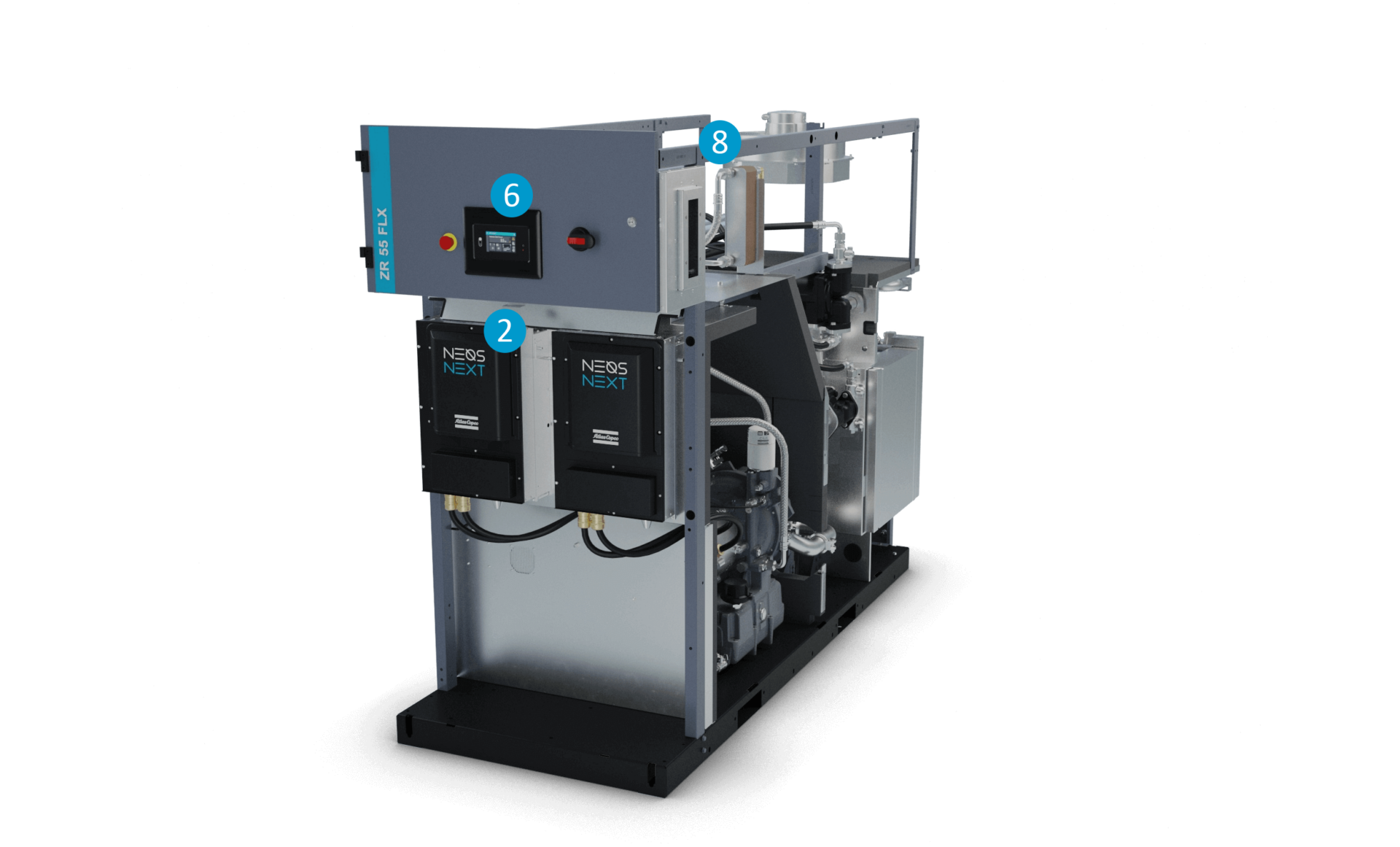

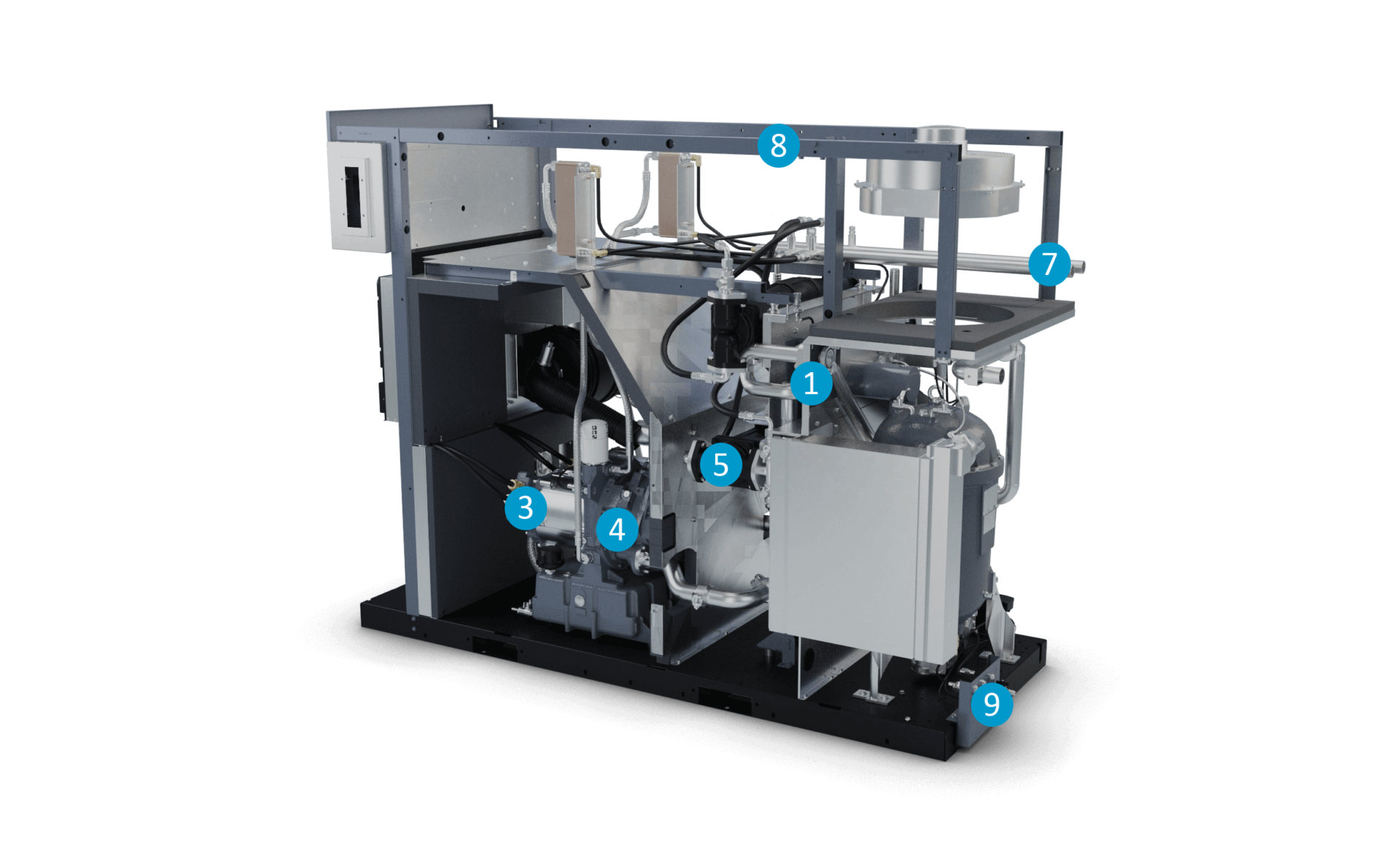

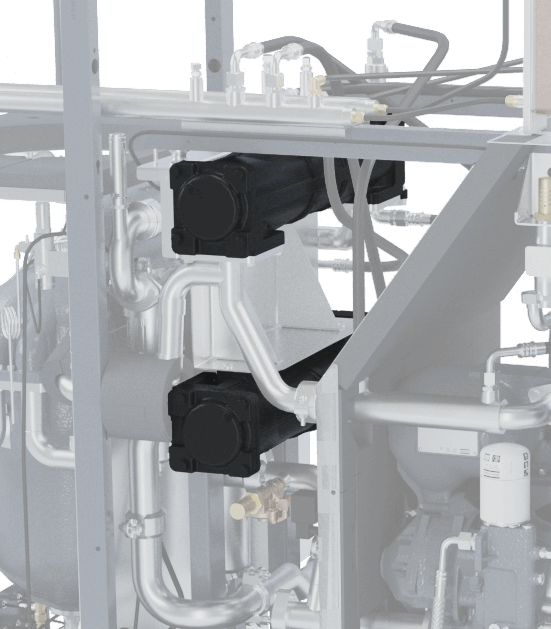

ZR 30-55 FLX FF (iMD)

ZR 30-55 FLX FF (iMD) Highlights Front

ZR 30-55 FLX FF (iMD) Highlights Back

-

1

Soundproof canopy

-

2

NEOS Next frequency converters

-

3

Permanent magnet motor

-

4

Oil-free tooth element

-

5

Reliable cooling

-

6

Advanced Elektronikon® monitoring system

-

7

Compact design

-

8

Low maintenance

-

9

Integrated dryer

-

Soundproof canopy

– Sound insulation allows for installation in most working environments.

– No need for a separate compressor room.

-

NEOS Next frequency converters

– Our patented NEOS Next designed for IP54 allows the unit to run at minimum speed during unload, reducing the unload power consumption to minimum.

– Designed to withstand temperatures up to 50°C/122°F.

-

Permanent magnet motor

– A proven design with a direct coupled permanent magnet drive motor for low- and high-pressure element, each with their own frequency converter.

– Our oil-cooled permanent magnet motors feature an IP66-rated enclosure which offers a complete protection against dust and powerful water jets to ensure reliable performance even in harsh operating environments.

– Optimized intercooler pressure across the entire speed range ensures stable operation and reinforces long-term reliability, even under demanding conditions.

-

Oil-free tooth element

Our oil-free tooth element is designed for dependable performance? It uses precision gears and durable bearings which reduce wear and keep the machine running smoothly, even under demanding conditions.

-

Reliable cooling

– Water-cooled oil coolers, intercooler, and aftercooler

– Frequency-controlled fan optimizes cooling for all running conditions

– Oil cooling shields permanent magnet motors from the environment and makes them more robust

-

Advanced Elektronikon® monitoring system

– User-friendly Elektronikon® Touch, with enhanced connectivity potential.

– Included warning indications, maintenance scheduling and online visualization of the machine’s condition for increased reliability.

-

Compact design

With its compact design, the Full Feature version offers substantial space savings and simplifies installation compared to traditional freestanding dryers.

-

Low maintenance

– Strategically placed components allow quick and easy access, simplifying maintenance and reducing downtime.

– Oil-lubricated motor bearings eliminate the need for re-greasing, ensuring long-lasting performance with minimal upkeep.

-

Integrated dryer

– Integrated dryer option reduces installation complexity and

minimizes footprint, lowering the risk of setup errors and ensuring

consistent performance.

– Available in both Refrigerant and Heat of Compression versions,

offering reliable drying performance tailored to different operating

needs.

– Heat of Compression version delivers dew point suppression of

over 30°C (86°F), ensuring dependable moisture control even in

demanding conditions.