Did you know that compressed air generation can amount to over 40% of a plant’s total electricity bill? And that energy consumption can account for over 80% of a compressor’s lifecycle cost? For businesses serious about increasing their profits, energy consumption is an obvious target. It was therefore one of the leading design priorities for our ZR/ZT 30-50 VSD⁺ compressors.

Building energy savings into your process

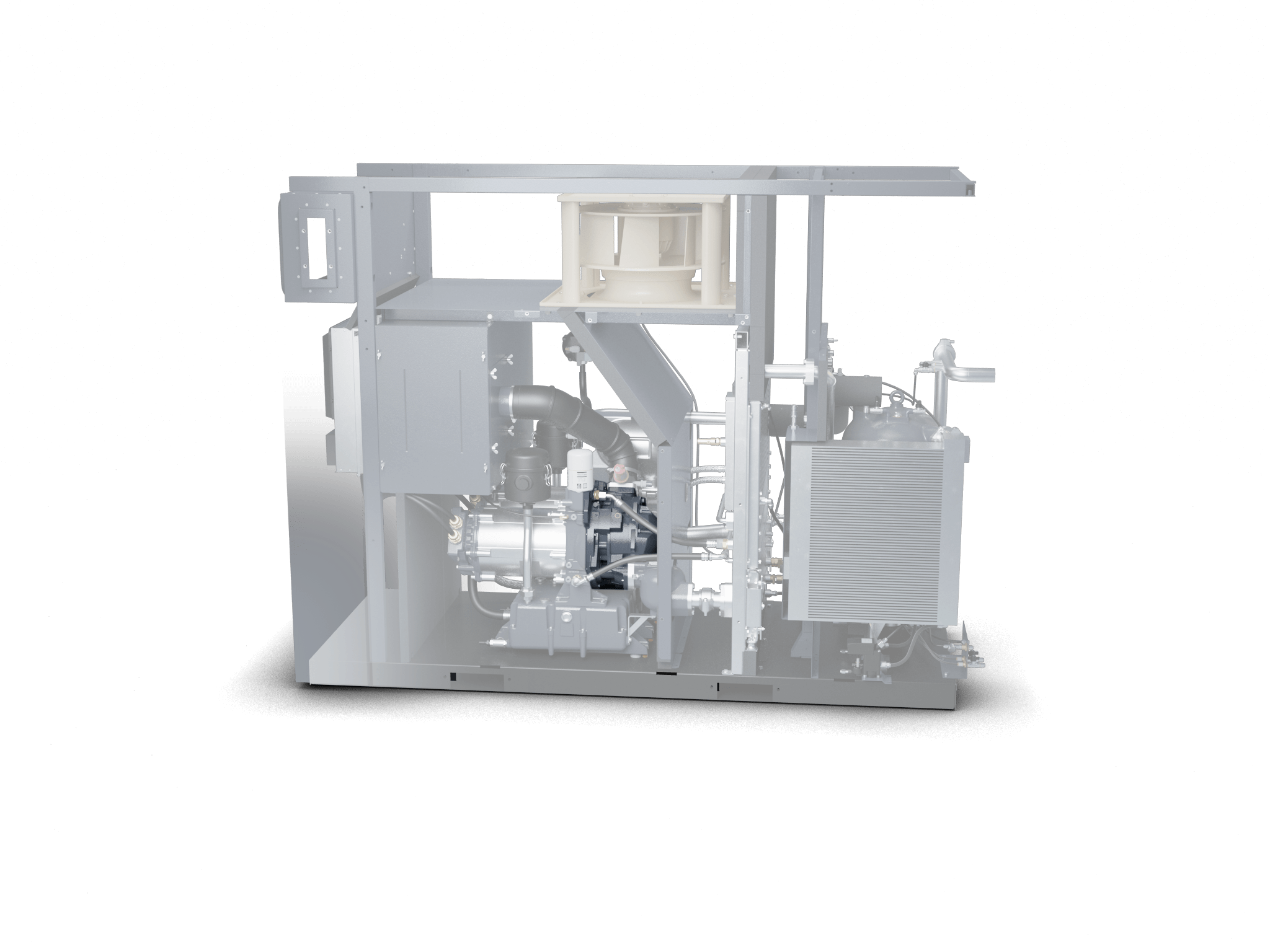

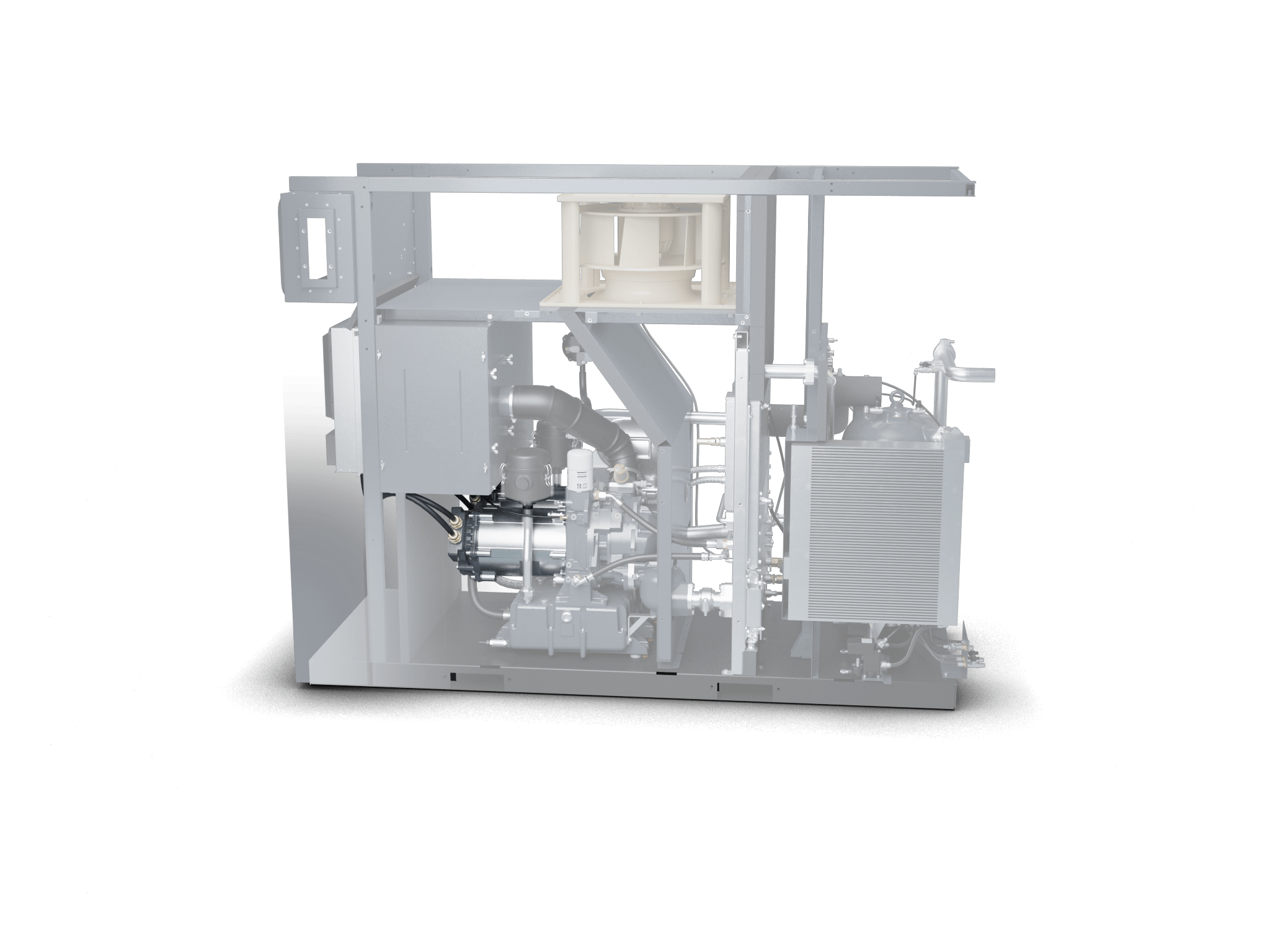

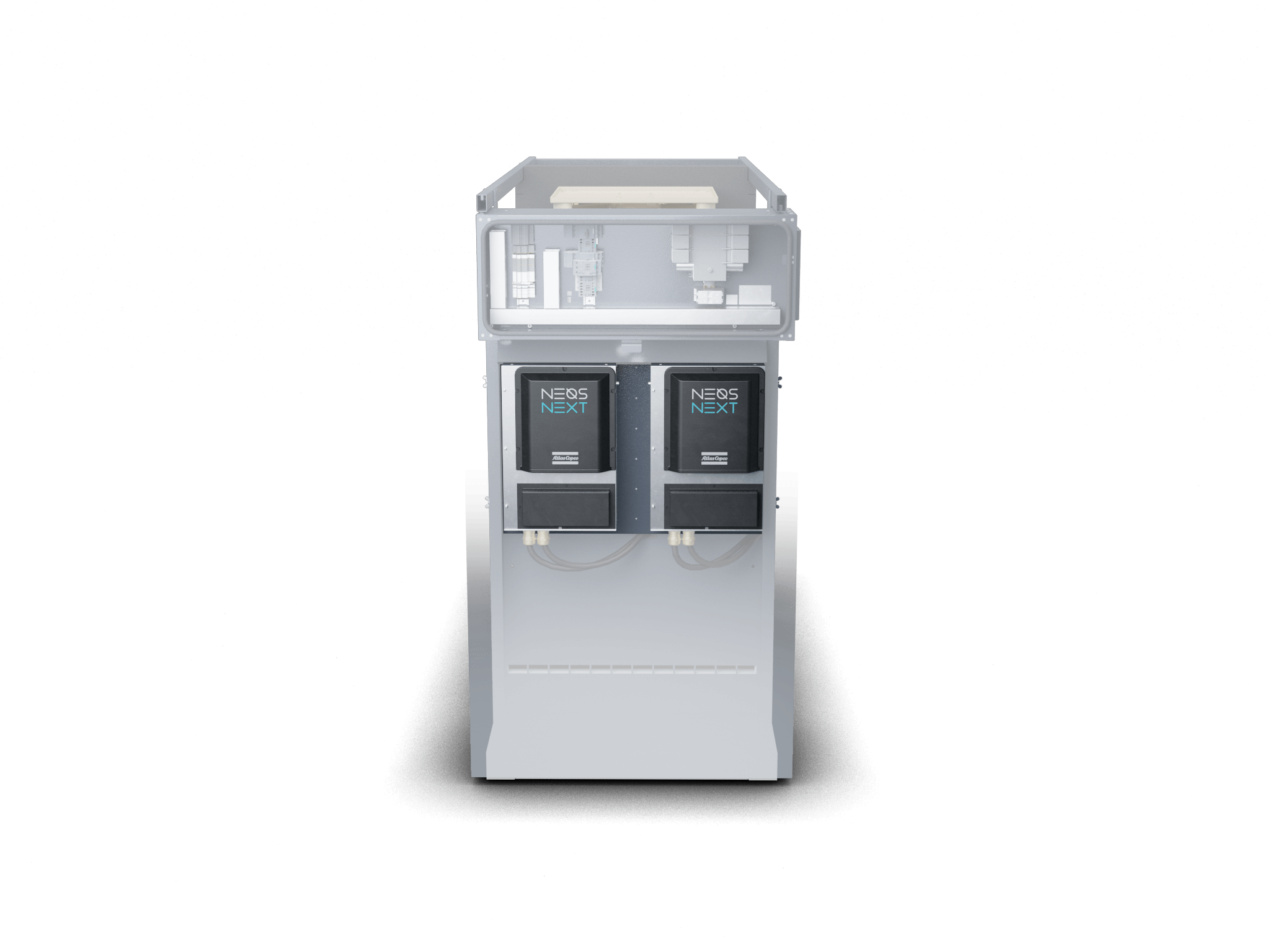

Energy-saving componentsOur engineers took every opportunity to reduce energy consumption in these machines. The patented elements are designed in-house for maximum efficiency. A superior coating on the active surfaces of the stainless steel rotors contributes to the most efficient oil-free tooth technology in this capacity range. A unique Z seal design further reduces running costs and guarantees 100% certified oil-free air for your application.  Oil-free Tooth ElementOur in-house designed oil-free tooth element boosts efficiency by delivering consistent, high-performance compression with minimal energy loss. Its streamlined design ensures low unload power, helping the machine use less energy while maintaining top output.  MotorThe IE5 permanent magnet motor in our oil-free tooth FLX machine achieves up to 97% energy efficiency, ensuring maximum power conversion and reduced energy consumption during operation  Neos NextOur patented NEOS Next drives improve energy efficiency by minimizing power use during unload and enabling smart speed control across varying air demands. |

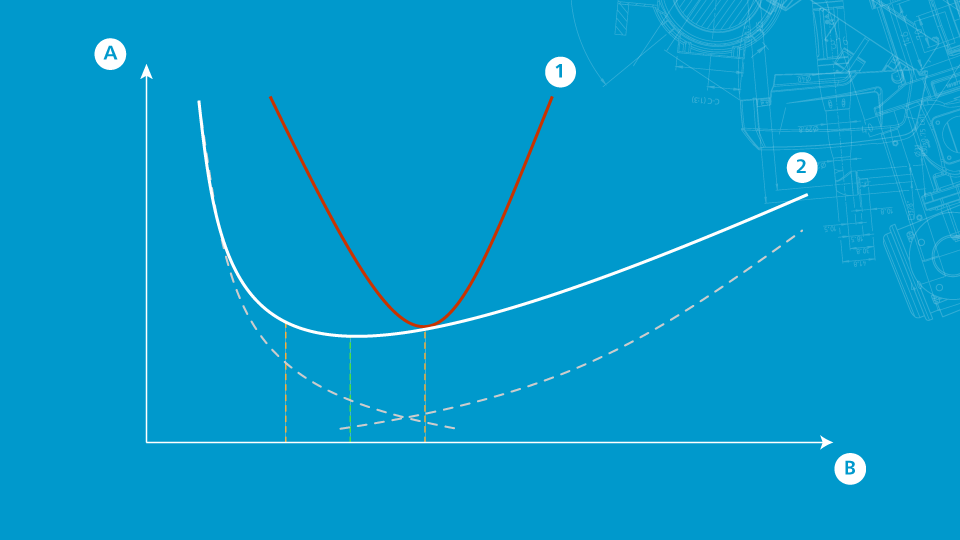

A= Losses

B = Speed

1 = Total losses traditional element

2 = Total losses AC element

VSD⁺ with dual NEOS drives

Atlas Copco pioneered VSD technology in the compressed air industry to offer major energy savings while protecting the environment for future generations. Today, we offer the widest range of integrated VSD compressors on the market.

VSD technology automatically adjusts the motor speed to air demand, reducing energy consumption by up to 35%. For the ZR/ZT 30-50 VSD⁺ range, we added a specially designed NEOS inverter to constantly optimize the motor speed, and our own Permanent Magnet Motor for class-leading efficiency.

Featuring dual NEOS drives, the ZR/ZT 30-50 VSD⁺ range has the widest operating range on the market. The units can operate from 28 to 100% load without wasting energy from unloaded operation, resulting in huge energy savings during periods of low to medium air demand. The dual NEOS drive system also keeps the compressor working at optimal efficiency – at any pressure – consuming less energy than a standard fixed speed machine or a VSD machine with a fixed gear ratio.